Method for catalytically synthesizing laminine by using solid and liquid phases

A technology of laminine and ethanol solution, applied in the field of preparation of high-purity laminine, can solve problems such as separation and purification difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The present invention, a kind of method of solid-liquid two-phase catalytic synthesis laminin, specifically comprises the following steps:

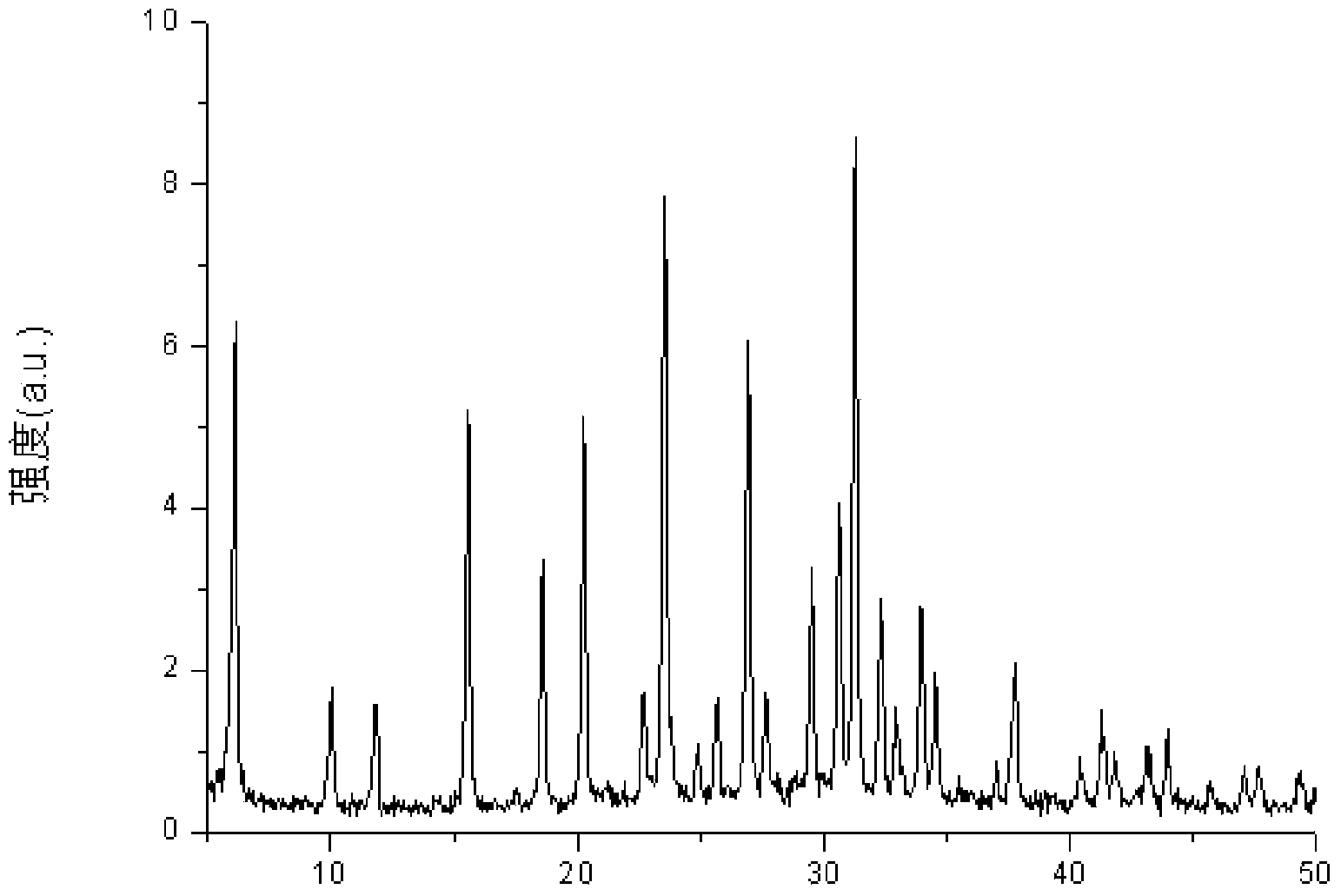

[0038] (1) Select 100 g of NaY molecular sieves with a high silicon-aluminum ratio of 6.7, soak them in a saturated acidic nickel chloride solution for 24 hours, filter, and dry at 120° C. for 1 hour. The nickel content is 6.04%, and the average particle size is 1.1 μm to obtain Na- Ni-Y molecular sieve Ⅰ;

[0039] (2) Weigh 100g Na-Ni-Y type molecular sieve I, mix it with 100g nickel chloride hexahydrate powder, put it in a muffle furnace, and heat it stepwise. The specific heating procedure is: first, the temperature rises every minute Increase by 2°C, keep the temperature constant for 45 minutes when it rises to 90°C; then turn to increase by 1°C per minute, and keep the temperature constant for 30 minutes when it rises to 140°C; finally turn to increase by 2°C per minute, keep the temperature for 2 hours when it rises to 1200°C; ...

Embodiment 2

[0048] The present invention, a kind of method of solid-liquid two-phase catalytic synthesis laminin, specifically comprises the following steps:

[0049] (1) Select 100 g of NaY molecular sieves with a high silicon-aluminum ratio greater than 7.0, soak them in a saturated acidic nickel chloride solution for 24 hours, filter, and dry at 120°C for 1 hour. The nickel content is 6.11%, and the average particle size is 1.3 μm, to obtain Na- Ni-Y type molecular sieve Ⅰ;

[0050] (2) Weigh 100g Na-Ni-Y type molecular sieve I, mix it with 100g nickel chloride hexahydrate powder, put it in a muffle furnace, and heat it stepwise. The specific heating procedure is: first, the temperature rises every minute Increase by 2°C, keep the temperature constant for 45 minutes when it rises to 90°C; then turn to increase by 1°C per minute, and keep the temperature constant for 30 minutes when it rises to 140°C; finally turn to increase by 2°C per minute, keep the temperature for 2 hours when it r...

Embodiment 3

[0054] (1) Select 100 g of NaY molecular sieves with a high silicon-aluminum ratio greater than 7.0, soak them in a saturated acidic nickel chloride solution for 24 hours, filter, and dry at 120°C for 1 hour. The nickel content is 6.11%, and the average particle size is 1.3 μm, to obtain Na- Ni-Y type molecular sieve Ⅰ;

[0055] (2) Weigh 100g Na-Ni-Y type molecular sieve I, mix it with 100g nickel chloride hexahydrate powder, put it in a muffle furnace, and heat it stepwise. The specific heating procedure is: first, the temperature rises every minute Increase by 2°C, keep the temperature constant for 45 minutes when it rises to 90°C; then turn to increase by 1°C per minute, and keep the temperature constant for 30 minutes when it rises to 140°C; finally turn to increase by 2°C per minute, keep the temperature for 2 hours when it rises to 1200°C; while hot Pour the mixed material into 1L of water under stirring, stir to normal temperature, filter and dry to obtain Na-Ni-Y type...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com