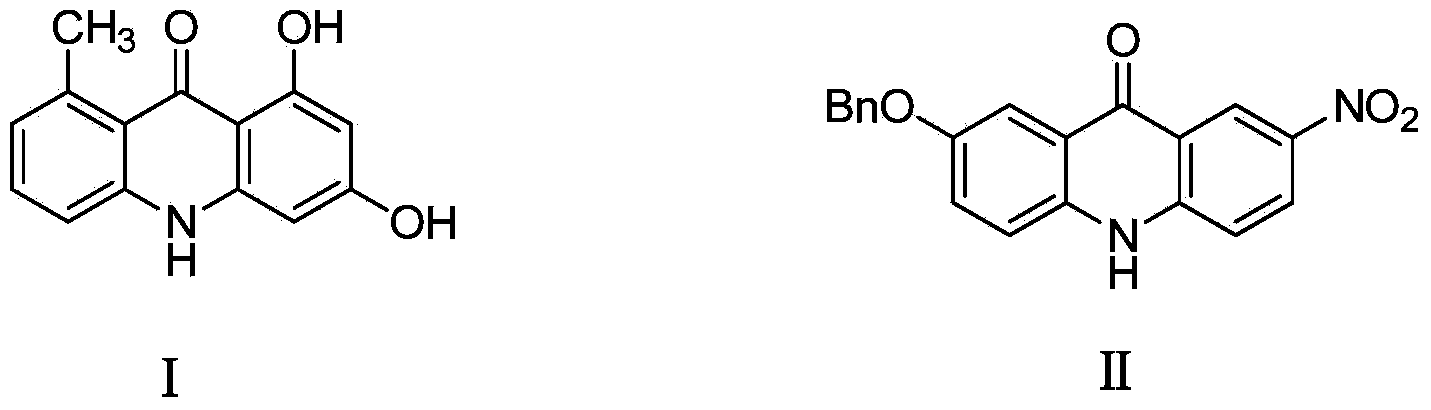

Preparation method of N-(2-hydroxy-5-methoxycarbonyl phenyl) acridone compound

A technology for methoxycarbonyl phenyl and compound, which is applied in the field of preparation of N-acridone compounds, can solve the problems of poor substrate adaptability, high reaction temperature, long reaction time and the like, and achieve sustainable development and utilization , The effect of convenient post-processing and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

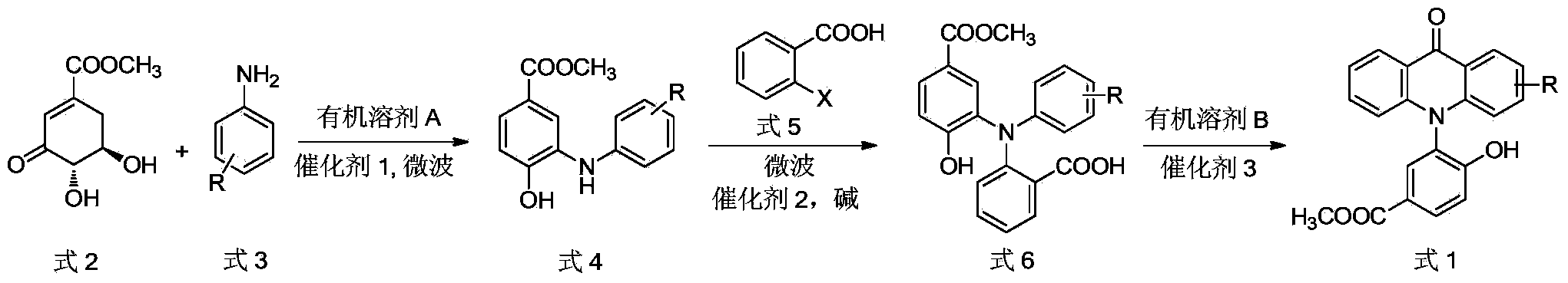

Method used

Image

Examples

Embodiment 1

[0031] The preparation of N-(2-hydroxyl-5-methoxycarbonylphenyl) acridone comprises the following steps:

[0032] Step 1: Methyl 3-dehydroshikimate (0.41g, 2.2mmol), aniline (0.19g, 2.0mmol), p-toluenesulfonic acid (19.0mg, 0.1mmol), 5ml N,N-dimethylformamide Add to the microwave reaction vial at one time. The reaction system was reacted at 130° C. for 8 min in a microwave reactor.

[0033] Step 2: Potassium carbonate (0.83g, 6mmol), cuprous oxide (0.14g, 1mmol), o-iodobenzoic acid (0.50g, 2mmol) were added to the above system and reacted in a microwave reactor at 130°C for 5min. The reaction was monitored by TLC. After the reaction was completed, it was cooled and filtered with suction. The filtrate was poured into 100ml of ice water and acidified with dilute hydrochloric acid. A large amount of off-white solids were precipitated, filtered with suction, dried, and recrystallized with ethyl acetate-petroleum ether to obtain white crystals N- Phenyl-N-(2-carboxyphenyl)-2-hydr...

Embodiment 2

[0037] The preparation of 2-methyl-9-(2-hydroxyl-5-methoxycarbonylphenyl) acridone comprises the following steps:

[0038] Step 1: Methyl 3-dehydroshikimate (0.19g, 1.0mmol), p-methylaniline (0.11g, 1.0mmol), p-toluenesulfonic acid (19.0mg, 0.1mmol), 5ml N,N-dimethyl Acetamide was added to the microwave reaction vial at one time. The reaction system was reacted at 80°C for 20 min in a microwave reactor.

[0039] Step 2: Potassium carbonate (0.55g, 4mmol), cuprous oxide (0.14mg, 0.1mmol), o-iodobenzoic acid (0.25g, 1mmol) were added to the above system and reacted in a microwave reactor at 100°C for 15min. The reaction was monitored by TLC. After the reaction was completed, it was cooled and filtered with suction. The filtrate was poured into 100ml of ice water and acidified with dilute hydrochloric acid. A large amount of off-white solid precipitated, filtered with suction, dried, and recrystallized with ethyl acetate-ethanol to obtain light yellow crystals N -(4-methylphenyl)...

Embodiment 3

[0043] The preparation of 2-bromo-9-(2-hydroxyl-5-methoxycarbonylphenyl) acridone comprises the following steps:

[0044] Step 1: Methyl 3-dehydroshikimate (0.45g, 2.4mmol), p-bromoaniline (0.35g, 2.0mmol), formic acid (4.6mg, 0.1mmol), and 5ml dimethyl sulfoxide were added to the microwave reaction at one time in the bottle. The reaction system was reacted at 180° C. for 3 min in a microwave reactor.

[0045] Step 2: Potassium carbonate (0.83g, 6mmol), cuprous oxide (0.29g, 2mmol), o-iodobenzoic acid (0.50g, 2mmol) were added to the above system and reacted at 160°C for 5min in a microwave reactor. The reaction was monitored by TLC. After the reaction was completed, it was cooled and filtered with suction. The filtrate was poured into 100ml of ice water and acidified with dilute hydrochloric acid. A large amount of off-white solids were precipitated, filtered with suction, dried, and recrystallized with dichloromethane-petroleum ether to obtain white crystals N -(4-bromophe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com