Preparation method of SAPO-34 molecular sieve

A technology of SAPO-34 and molecular sieve, applied in the field of preparation of SAPO-34 molecular sieve, can solve the problems of difficult solid-liquid separation, material loss and high cost, and achieve the effects of large specific surface area, easy operation and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

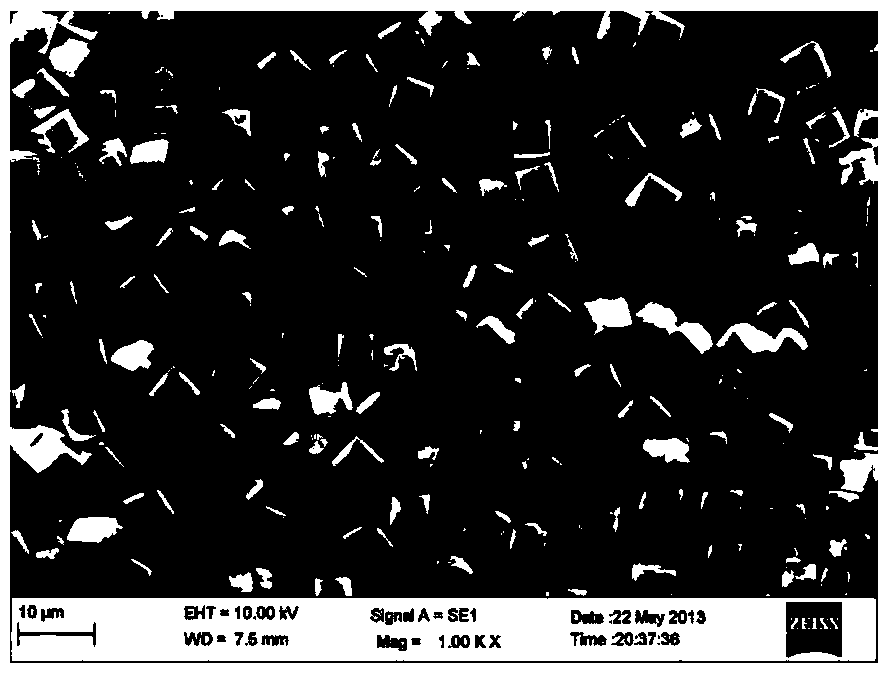

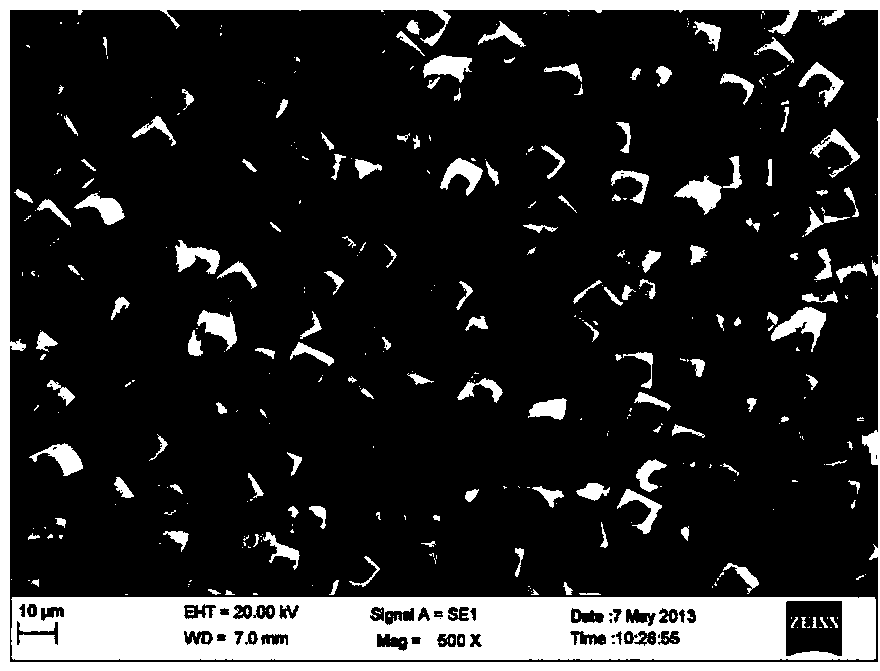

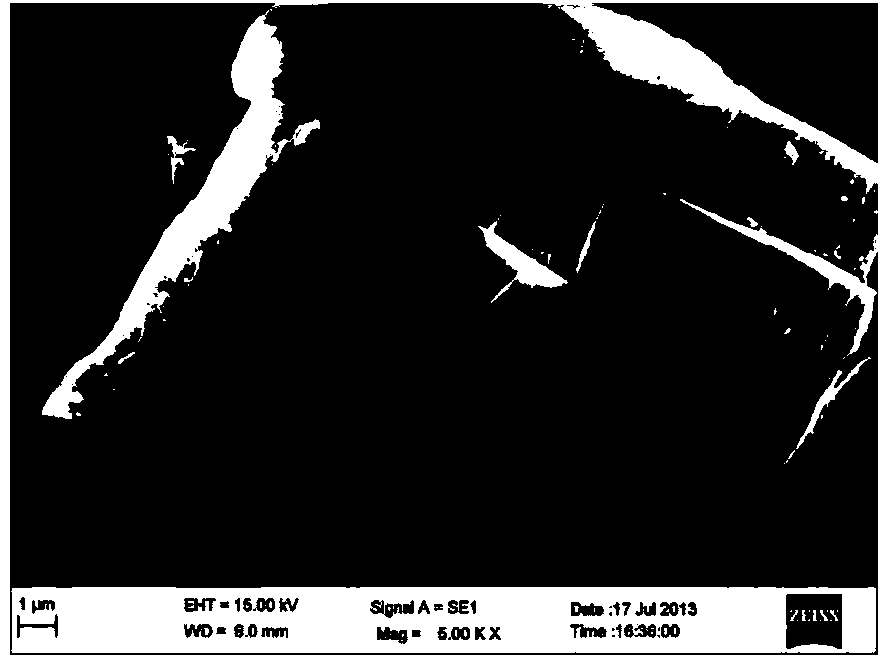

[0047] Under stirring at room temperature, 105.8g of pseudo-boehmite (Al 2 o 3 Content is 76.5%) drop into 500g deionized water, then add 183.0g orthophosphoric acid (H 3 PO 4 content is 85%) and 183.0g deionized water, increase the stirring speed to 600 rpm, after stirring for 2h, add 63.5g silica sol (SiO 2 content is 30%) and 38.5g deionized water, 186.7g morpholine, and 162.9g TMAmOH aqueous solution (TMAmOH content is 25%) and 40.0g deionized water, increase stirring speed to 800 rev / min, form uniform after stirring 5h Gel; then transfer the gel to a 2L crystallization kettle, add 3g of seed crystal mixture (0.95g of seed crystal content), set the stirring speed at 120 rpm, and heat up to 190°C for crystallization 24h. After the crystallization is completed, the mixed solution is filtered, washed, dried, roasted and other post-treatments to obtain the target product, which is named B. After XRD and SEM characterization tests, it is found that the target product B pre...

Embodiment 2

[0049] Under stirring at room temperature, 115.6g of aluminum hydroxide was dropped into 750g of deionized water, and then 170.8g of orthophosphoric acid (H 3 PO 4 content is 85%) and 170g deionized water, increase the stirring speed to 600 rpm, after stirring for 2h, add 88.9g silica sol (SiO 2 content is 30%) and 48.4g deionized water, 209.5g triethylamine, and 124.8g TMAdOH aqueous solution (TMAdOH content is 25%) and 50.0g deionized water, increase the stirring speed to 800 rpm, and form a uniform mixture after stirring for 2 hours Gel; then transfer the gel to a 2L crystallization kettle, add 3g of seed crystal mixture solution (seed crystal content is 0.76g), set the stirring speed to 100 rpm, and heat up to 180°C for crystallization 48h. After the crystallization is completed, the mixed solution is filtered, washed, dried, roasted and other post-treatments to obtain the target product, which is named C. After XRD and SEM characterization tests, it was found that the ...

Embodiment 3

[0051] Under stirring at room temperature, 123.8g of aluminum hydroxide was dropped into 600.0g of deionized water, and then 183.0g of orthophosphoric acid (H 3 PO 4 content is 85%) and 183.0g deionized water, increase the stirring speed to 600 rpm, after stirring for 2h, continuously add 95.2g silica sol (SiO 2 content is 30%) and 42.6g deionized water, 192.4g triethylamine, and 50.5g aqueous solution of N-methyl-3-quinoniol hydroxide (N-methyl-3-quinoniol hydroxide content is 25 %) and 30.0g deionized water, increase the stirring speed to 800 rpm, and form a uniform gel after stirring for 2h; then transfer the gel to a 2L crystallization kettle, and add 3g seed crystal mixed solution (seed crystal content 0.81g), the stirring speed was set at 80 rpm, and the temperature was raised to 180°C for 48 hours of crystallization. After the crystallization is completed, the mixed solution is filtered, washed, dried, roasted and other post-treatments to obtain the target product, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com