Resistance strain load sensor for high pressure hydrogen sulfide environment

A resistance strain type, load sensor technology, used in instruments, measuring devices, measuring forces, etc., can solve the problems of lack of material/machine durability testing equipment and technology, no direct safety testing, etc., to extend service life, Guaranteed effect of accuracy and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

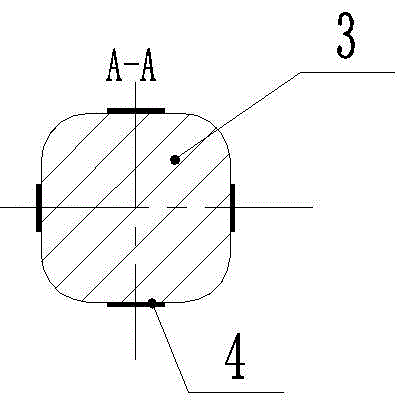

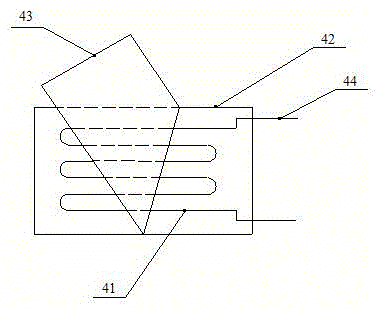

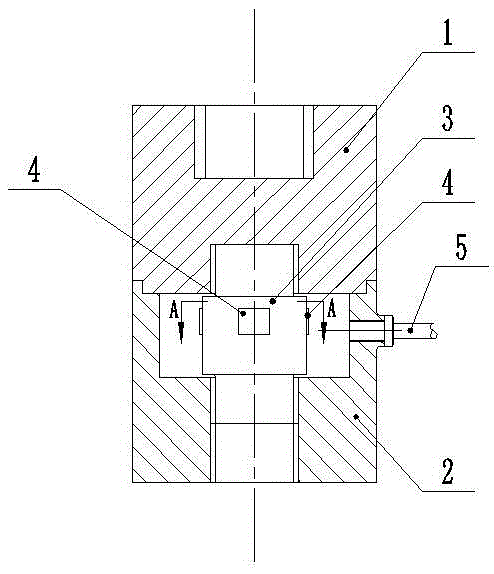

[0027] A load cell in a high-pressure hydrogen sulfide environment (such as figure 1 , 2 shown), including the upper sensor case 1, the lower sensor case 2 and the elastic body 3. The materials for the upper sensor case 1, the lower sensor case 2 and the elastic body 3 are all made of C-276 Hastelloy (commercially available), and the elastic body 3 are respectively threadedly connected with the sensor upper shell 1 and the sensor lower shell 2, and the middle part of the elastic body 3 is evenly distributed with foil strain gauges 4, and there is a piece of foil strain gauge 4 in the middle of each of the four faces of the middle part of the elastic body 3. The foil strain gauges 4 on the front and rear surfaces of the middle part of the body 3 are arranged laterally (refer to the attached image 3 ), the foil strain gauges 4 on the left and right surfaces in the middle of the elastic body 3 are arranged longitudinally, the foil strain gauges 4 are bonded to the elastic body ...

Embodiment 2

[0032] The difference between this embodiment and Embodiment 1 is that the thickness of the sensitive grid is 20 μm, and the composition of each element in the iron-based alloy by mass percentage is: the composition of each element in the iron-based alloy by mass percentage is: chromium 25%, 2% nickel, 2% molybdenum, 1% aluminum, 70% iron; the thickness of the iron transition layer is 100nm, and the thickness of the aluminum-zinc alloy layer is 100nm. The composition of each element of the aluminum-zinc alloy in terms of mass percentage is: 5% zinc and 95% aluminum.

[0033] The thickness of the aluminum oxide protective layer is 10nm, and the processing parameters of the plasma oxidation technology are: the frequency of the radio frequency source used is 15MHz, and the power of the radio frequency source is 2W / cm 2 , the gas source is a mixed gas mixed with argon and oxygen at a volume ratio of 10:1, the gas flow rate is 49 sccm, and the reaction chamber pressure is 8×10 4 P...

Embodiment 3

[0036] The difference between this embodiment and Embodiment 1 is that the thickness of the sensitive grid is 15 μm, and the composition of each element of the iron-based alloy in terms of mass percentage is: 10% chromium, 5% nickel, 4% molybdenum, 4% aluminum, iron 77%; the thickness of the iron transition layer is 100nm, and the thickness of the aluminum-zinc alloy layer is 100nm. The composition of each element of the aluminum-zinc alloy in terms of mass percentage is: 20% zinc and 80% aluminum.

[0037] The thickness of the aluminum oxide protective layer is 5nm, and the processing parameters of the plasma oxidation technology are: the frequency of the radio frequency source used is 12MHz, and the power of the radio frequency source is 2W / cm 2 , the gas source is a mixed gas mixed with argon and oxygen at a volume ratio of 7:1, the gas flow rate is 49 sccm, and the reaction chamber pressure is 5×10 4 Pa, the sensitive gate temperature is controlled at 250°C, and the oxida...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com