Soft capsule health food capable of protecting liver and preparation method of food

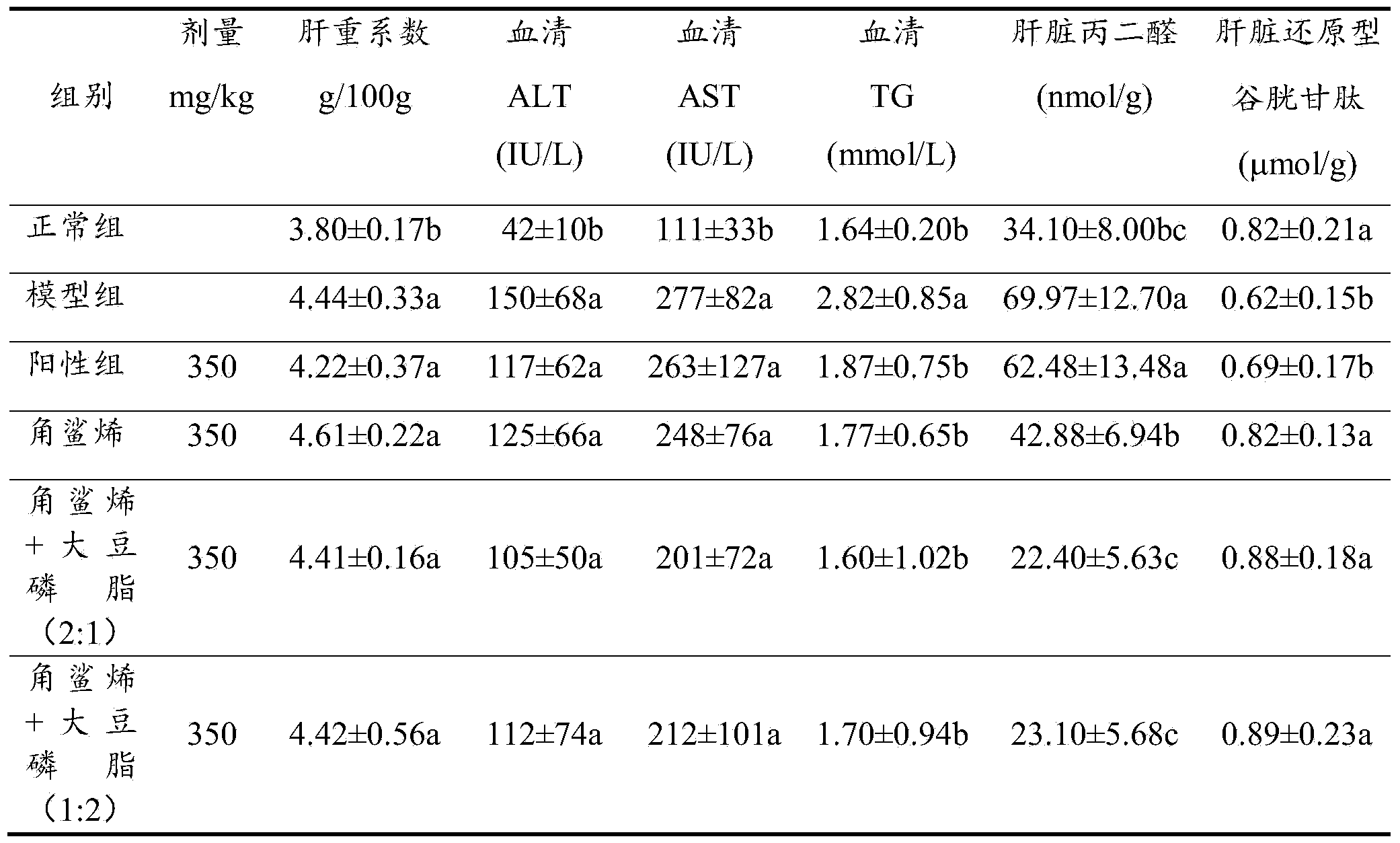

A technology for health food and soft capsule, which is applied in the directions of food preparation, food processing, food processing, etc., can solve the problem of no public technology of compounding squalene and soybean lecithin, and no public technology of compounding squalene and soybean lecithin. Specific dosage forms and other issues, to achieve the effect of improving the protective effect, improving the protective effect, and reducing the content of malondialdehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] Step 1: Ingredients

[0059] (1) Prepare the contents of the soft capsule: at normal temperature, take 60 parts of squalene, 20 parts of soybean lecithin and 40 parts of vegetable oil by weight, grind on a colloid mill for 30 minutes to obtain a uniform liquid, which is ready for use;

[0060] (2) Glue preparation: Weigh 100 parts of gelatin, 30 parts of glycerin, 80 parts of purified water, 2-4 parts of sorbitol, and 2 parts of brown iron oxide, put them into the plastic bucket, heat up to 60°C, and stir for 4 Hours, keep warm at 50°C, place for 6 hours, degas, and set aside.

[0061] Step 2: Press the pill

[0062] The contents of the prepared soft capsules and the glue are respectively transported into the pelletizing machine, and the ambient temperature is controlled at 26°C and the relative humidity is 30%. Start the pill press machine, press the soft capsule, the speed is 4r / min, the rubber thickness is controlled at 0.78-0.85mm, the weight of the capsule conten...

Embodiment 2

[0072] Step 1: Ingredients

[0073] (1) Prepare the contents of the soft capsule: at normal temperature, take 60 parts of squalene, 30 parts of soybean lecithin and 40 parts of vegetable oil by weight, grind on a colloid mill for 30 minutes to obtain a uniform liquid, which is ready for use;

[0074] (2) Glue preparation: Weigh 100 parts of gelatin, 40 parts of glycerin, 80 parts of purified water, 3 parts of sorbitol, and 2 parts of brown iron oxide, put them into the plastic bucket, heat up to 60°C, and stir for 4 hours. Insulate at 50°C, place for 6 hours, degas, and set aside.

[0075] Step 2: Press the pill

[0076] The contents of the prepared soft capsules and the glue are respectively transported into the pelletizing machine, and the ambient temperature is controlled at 26°C and the relative humidity is 30%. Start the pill press machine, press the soft capsule, the speed is 4r / min, the rubber thickness is controlled at 0.78-0.85mm, the weight of the capsule content i...

Embodiment 3

[0086] Step 1: Ingredients

[0087] (1) Prepare the contents of the soft capsule: at normal temperature, take 80 parts of squalene, 30 parts of soybean lecithin and 50 parts of vegetable oil by weight, and grind for 60 minutes on a colloid mill to obtain a uniform liquid, which is used for equipment;

[0088] (2) Glue preparation: Weigh 100 parts of gelatin, 40 parts of glycerin, 80 parts of purified water, 3 parts of sorbitol, and 2 parts of brown iron oxide, put them into the plastic bucket, heat up to 60°C, and stir for 4 hours. Insulate at 50°C, place for 6 hours, degas, and set aside.

[0089] Step 2: Press the pill

[0090] The contents of the prepared soft capsules and the glue are respectively transported into the pelletizing machine, and the ambient temperature is controlled at 26°C and the relative humidity is 30%. Start the pill press machine, press the soft capsule, the speed is 4r / min, the rubber thickness is controlled at 0.78-0.85mm, the weight of the capsule ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com