Process for extracting and refining natural borneol

A natural borneol and process technology, which is applied in the separation/purification of essential oils/fragrance, hydroxyl compounds, and fat production, can solve the problems of inability to improve oil separation efficiency, reduction of primary product yield, increase of impurity products, etc., and achieve loss Small, improve recovery rate, increase the effect of borneol content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

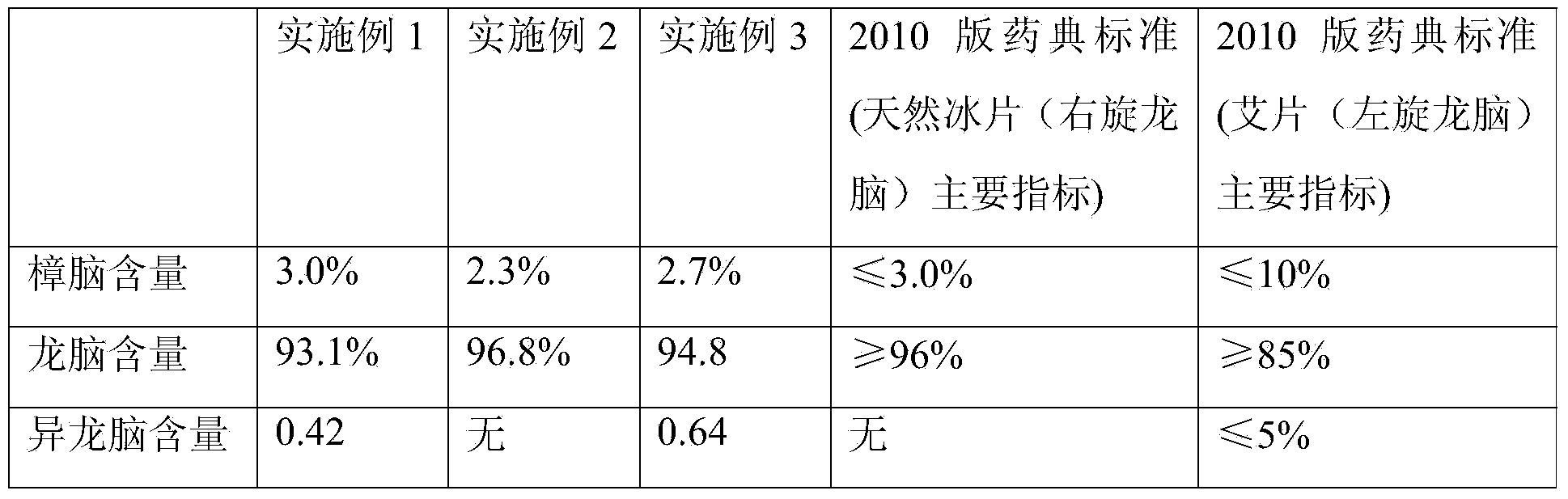

Embodiment 1

[0022] Distill and extract the plant Ai Naxiang in sus304 stainless steel to obtain the primary extract of Ai Naxiang containing water. Send 20kg of the primary extract of Aiinaxiang containing water into a centrifuge for centrifugal dehydration at a speed of 4000rpm, and the oily water is separated from the oil by standing. Spray 0.2wt% sodium dodecyl benzene sulfonate solution (can be sprayed by setting water nozzle in the centrifuge) in the centrifuge again, further wash and remove the residual Aina sesame oil composition in the initial extract of the plant, After being dehydrated by a centrifuge, the product also contains about 26% moisture. Then send it to a vacuum dryer and dry it under the condition of a vacuum degree of 0.03MPa and a temperature of about 60°C. After drying, the moisture content of the product is reduced to below 1%. Then put it into the sublimation crystallization kettle to vacuumize the air in the kettle to 0.01MPa (absolute vacuum), then fill it with...

Embodiment 2

[0024] The plant borneol camphor is distilled and extracted in a glass-lined reactor to obtain the initial extract of borneol camphor containing water, and 20 kg of the initial extract of borneol camphor containing water is sent to a centrifuge for dehydration at a speed of 2000 rpm, and the oily water is separated from the oil by standing . Then spray 0.1wt% fatty acid sucrose ester solution into the centrifuge, further wash and remove the residual liquid oil components in the plant initial extract, and also contain about 26% moisture after dehydration by the centrifuge, and then send it into a vacuum dryer Vacuum degree of 0.03MPa is dried at about 70°C, and the moisture content of the product after drying is reduced to below 1%. Then put it into the sublimation crystallization kettle, pump the air in the kettle to 0.01MPa, fill it with nitrogen to 0.09MPa, raise the temperature to 110°C and keep it for 100 minutes, then raise the temperature to 215°C, stop heating after abo...

Embodiment 3

[0026] Distill and extract the plant Ainaxiang in sus304 stainless steel by conventional methods to obtain 20 kg of the initial extract with a water content of about 50%, and send it to a centrifuge for dehydration at a speed of 4000rpm, and the oily water is separated from the oil after standing. Then spray 0.07wt% AEO9 solution into the centrifuge to further wash and remove the residual liquid oil components in the initial plant extract. After being dehydrated by the centrifuge, it still contains about 26% water, and then sent to a vacuum dryer at about 60°C Dry under vacuum at low temperature. Then put it into the sublimation crystallization kettle, pump the air in the kettle to 0.01MPa, fill it with nitrogen to 0.08MPa, raise the temperature to 120°C for 80 minutes, then raise the temperature to 185°C, stop heating after about 12 hours after the borneol sublimation is completed, and put the crystallization plate Take out the shoveled ice flake crystals.

[0027] The appea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com