A Terpolymerized Polynaphthaleneimide with Widely Adjustable Information Storage Behavior and Its Preparation

A polynaphthalimide, ternary copolymerization technology, applied in electrical components, circuits, electric solid devices, etc., can solve problems such as disappearance, optimization of storage performance, and restricted monomer structure in molecular design, and achieves practicability. Strong, easy-to-prepare effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 4,4'-diaminotriphenylamine, 9,9'-bis(aminophenyl)fluorene, 1,4,5,8-naphthalene tetracarboxylic anhydride molar ratio of 0:100:100 terpolymerized polynaphthalene Preparation of imide:

[0031] Under nitrogen protection, 2.68g (10.0mmol) of 1,4,5,8-naphthalene tetracarboxylic anhydride, 3.48g (10.0mmol) of 9,9'-bis(aminophenyl)fluorene were added to a 100mL three-necked flask, and then Add 50ml of m-cresol (treated) and stir in a closed environment at room temperature for 2 hours. When the solution is evenly stirred, add the dehydrating agent isoquinoline under nitrogen protection, and simultaneously raise the temperature to 200°C for continuous reaction for 12 hours. After cooling, the polymer is repeatedly precipitated with methanol and dried to obtain 4,4'-diaminotriphenylamine, 9,9'-bis(aminophenyl)fluorene, 1,4,5,8-naphthalene Tetraformic anhydride molar ratio of 0:100:100 terpolymer polynaphthaleneimide solid.

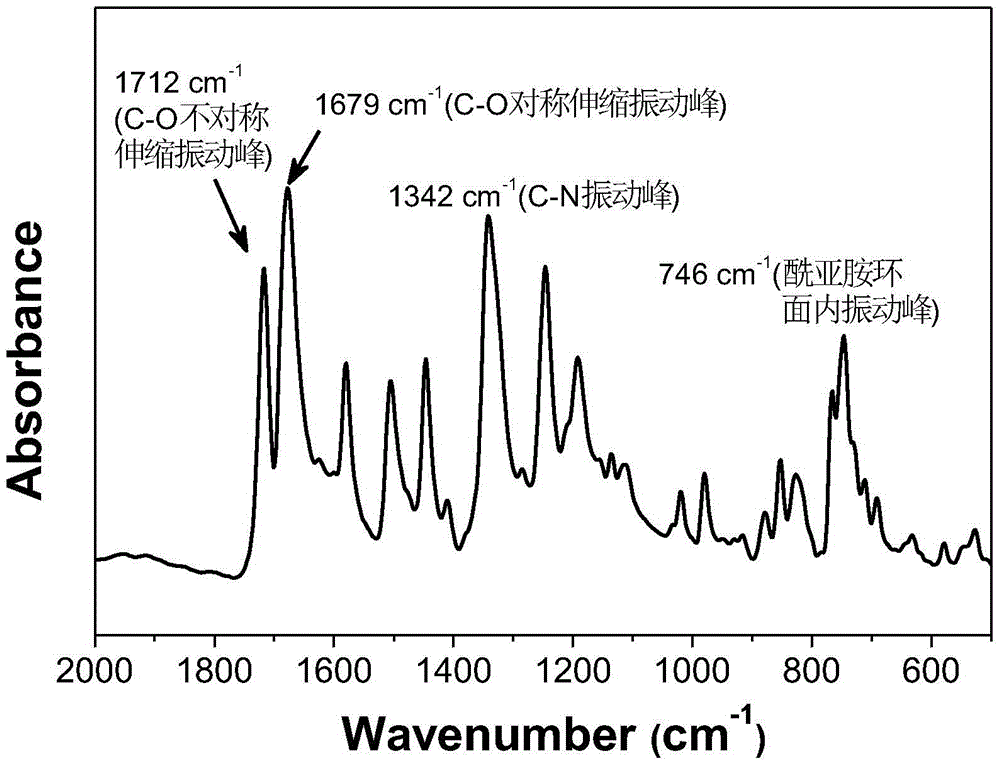

[0032] Infrared (KBr tablet): 1712cm -1 (C-O asymme...

Embodiment 2

[0034] 4,4'-diaminotriphenylamine, 9,9'-bis(aminophenyl)fluorene, 1,4,5,8-naphthalene tetracarboxylic anhydride in molar ratio of 1:99:100 terpolymerized polynaphthalene Preparation of imide:

[0035] Under nitrogen protection, 2.68g (10.0mmol) 1,4,5,8-naphthalene tetracarboxylic anhydride, 3.45g (9.9mmol) 9,9'-di(aminophenyl)fluorene, 0.03g (0.1mmol) 4 , Add 4'-diaminotriphenylamine into a 100mL three-necked flask, then add 50ml of m-cresol (treated) and stir in a closed environment at room temperature for 2 hours. When the solution is evenly stirred, add the dehydrating agent isoquinoline under nitrogen protection , while raising the temperature to 200°C for continuous reaction for 12 hours. After cooling, the polymer is repeatedly precipitated with methanol and dried to obtain 4,4'-diaminotriphenylamine, 9,9'-bis(aminophenyl)fluorene, 1,4,5,8-naphthalene Tetraformic anhydride molar ratio of 1:99:100 terpolymer polynaphthaleneimide solid.

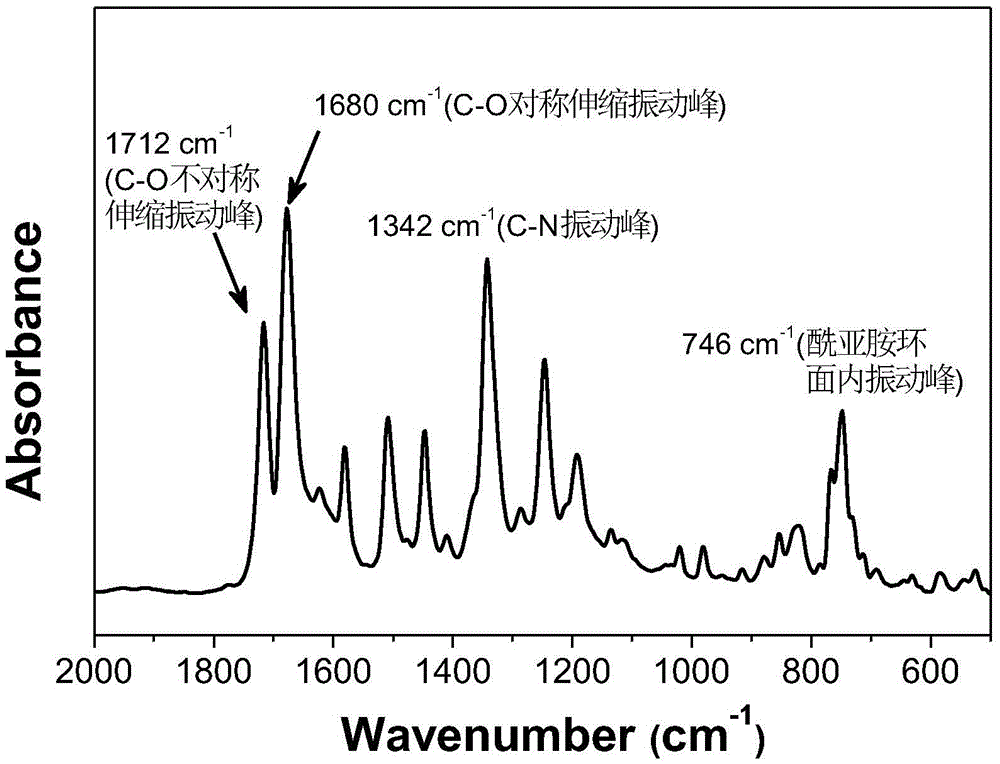

[0036] Infrared (KBr tablet): 1...

Embodiment 3

[0038] 4,4'-diaminotriphenylamine, 9,9'-bis(aminophenyl)fluorene, 1,4,5,8-naphthalene tetracarboxylic anhydride in a molar ratio of 2:98:100 terpolymerized polynaphthalene Preparation of imide:

[0039] Under nitrogen protection, 2.68g (10.0mmol) 1,4,5,8-naphthalene tetracarboxylic anhydride, 3.41g (9.8mmol) 9,9'-di(aminophenyl)fluorene, 0.06g (0.2mmol) 4 , Add 4'-diaminotriphenylamine into a 100mL three-necked flask, then add 30ml m-cresol (treated) and stir in a closed environment at room temperature for 2 hours. When the solution is evenly stirred, add the dehydrating agent isoquinoline under nitrogen protection , while raising the temperature to 200°C for continuous reaction for 12 hours. After cooling, the polymer is repeatedly precipitated with methanol and dried to obtain 4,4'-diaminotriphenylamine, 9,9'-bis(aminophenyl)fluorene, 1,4,5,8-naphthalene Tetraformic anhydride molar ratio is 2:98:100 terpolymer polynaphthalimide solid.

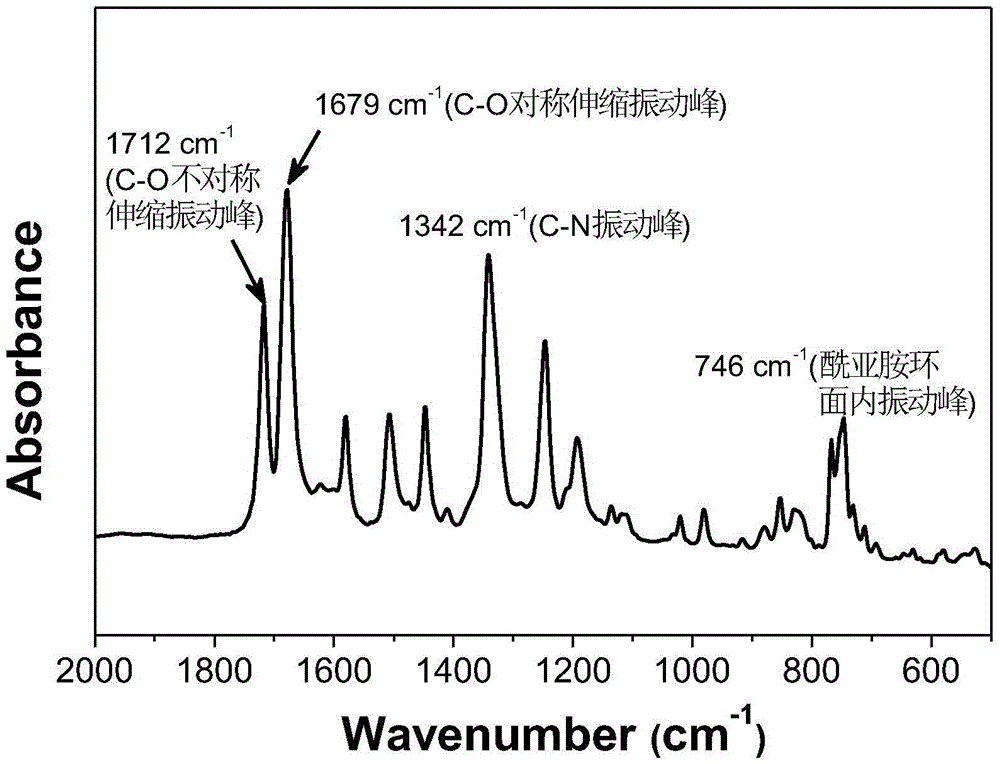

[0040] Infrared (KBr tablet): 1712c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com