Surface protecting agent for phenolic foam heat-insulating plate

A technology of phenolic foam and thermal insulation board, which is applied in the direction of coating, etc., can solve the problems of low bonding strength between the coating film and the surface of the phenolic foam thermal insulation board, affecting the quality of building thermal insulation projects, and incapable of industrial continuous production, etc., and achieves a small footprint , fast film forming speed and high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A face protection agent for phenolic foam insulation boards, which is composed of the following raw materials in parts by weight:

[0043] Resin acrylic emulsion 50 parts,

[0044] Vinyl emulsion 8 parts,

[0045] 5 parts dry oil,

[0046] Sodium base white bentonite 5 parts,

[0047] 2 parts of nonionic surfactant 5044,

[0048] Sodium salt nonionic surfactant 1 part,

[0049] 1 part of tributyl phosphate,

[0050] Alcohol ester-12 2 parts,

[0051] Silane coupling agent KH-550 3 parts,

[0052] 6 parts of talcum powder,

[0053] Sharp white TIO2 35 parts,

[0054] 15 parts of clean water;

[0055] Put each component of the raw material into the high-speed disperser and stir for 30 minutes until the raw material is evenly mixed and there are no particles.

Embodiment 2

[0057] A face protection agent for phenolic foam insulation boards, which is composed of the following raw materials in parts by weight:

[0058] Silane graft modified acrylic emulsion 55 parts,

[0059]Vinyl acetate emulsion 10 parts,

[0060] Drying oil 10 parts,

[0061] Sodium base white bentonite 10 parts,

[0062] 3 parts of nonionic surfactant 5044,

[0063] 2 parts of sodium salt nonionic surfactant,

[0064] 2 parts of tributyl phosphate,

[0065] Alcohol ester-12 3 parts,

[0066] Silane coupling agent A-178 5 parts,

[0067] Talcum powder 10 parts,

[0068] Sharp white TIO2 5 parts,

[0069] 20 parts of clean water;

[0070] Put each component of the raw material into the high-speed disperser and stir for 30 minutes until the raw material is evenly mixed and there are no particles.

Embodiment 3

[0072] A face protection agent for phenolic foam insulation boards, which is composed of the following raw materials in parts by weight:

[0073] Resin acrylic emulsion 52 parts,

[0074] Vinyl emulsion 9 parts,

[0075] 8 parts dry oil,

[0076] Sodium base white bentonite 8 parts,

[0077] 2.5 parts of nonionic surfactant 5044,

[0078] Sodium salt nonionic surfactant 1.5 parts,

[0079] 1.5 parts of tributyl phosphate,

[0080] Alcohol ester-12 2.5 parts,

[0081] Silane coupling agent KH-550 4 parts,

[0082] 8 parts of talcum powder,

[0083] Sharp white TIO2 4 parts,

[0084] 18 parts of clean water;

[0085] Put each component of the raw material into the high-speed disperser and stir for 30 minutes until the raw material is evenly mixed and there are no particles.

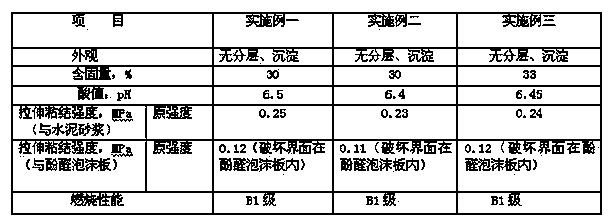

[0086] The surface protectors of the phenolic foam insulation boards in the above three embodiments can be directly sprayed, brushed or dipped to a certain thickness, and then formed into a film b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com