Rosin ester-containing flux composition and solder paste composition for soldering

A composition and flux technology, applied in the field of flux composition and solder paste composition, can solve the problems of easy brittleness of flux residue, cracking of flux residue, corrosion of circuit metal, etc. The effect of suppressing stickiness and improving workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0094] Hereinafter, although an Example and a comparative example are given and this invention is demonstrated in detail, this invention is not limited to these Examples.

[0095]

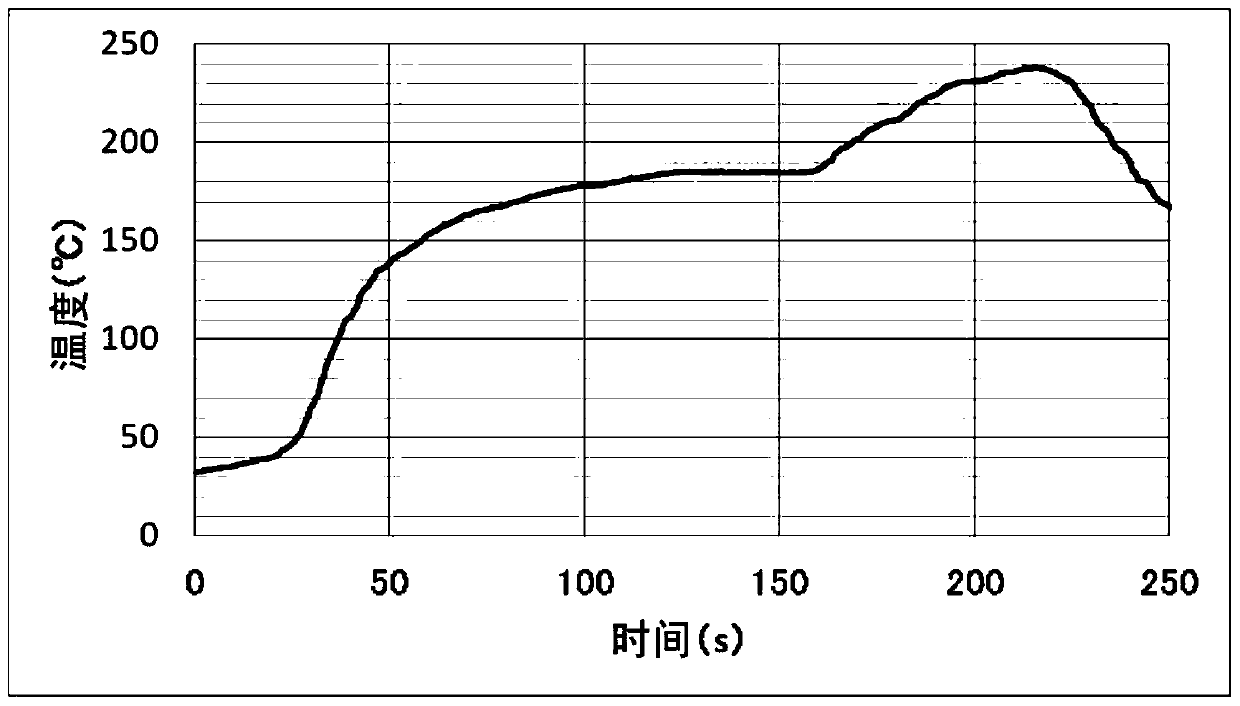

Synthetic example 1)

[0097] 138.6 g of hydrogenated acid-modified rosin (PINECRYSTAL KE-604, manufactured by Arakawa Chemical Industry Co., Ltd.) (COOH group: 0.6 mol) and 85.5 g (OH group: 0.3 mol) of dimer diol (PRIPOL2033, manufactured by CRODA JAPAN KK) were stirred at 150° C. for 1 hour under a nitrogen atmosphere to dissolve the hydrogenated acid-modified rosin.

[0098] Next, 5.7 g (0.03 mol) of p-toluenesulfonic acid monohydrate was added thereto, and the temperature was raised to 180° C. to perform a dehydration reaction. These were reacted for 3 hours until the dehydration stopped, and then left to cool to room temperature, and 200 g of ethyl acetate was further added to form a uniform solution.

[0099] It was neutralized with saturated sodium bicarbonate aqueous solution, liquid-separated, and concentrated to obtain 190.5 g of modified rosin A (acid value: 77 mgKOH / g, weight average molecular weight: 2,400).

Synthetic example 2)

[0101] As in Synthesis Example 1, 92.4 g (COOH group: 0.4 mol) of hydrogenated acid-modified rosin (PINECRYSTAL KE-604, manufactured by Arakawa Chemical Industry Co., Ltd.), alcohol-modified product of dimer acid (PRIPLAST1838, CRODA JAPAN KK 200.0 g (OH group: 0.2 mol) to obtain 248.2 g of modified rosin B (acid value: 39 mgKOH / g, weight average molecular weight: 7,800).

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com