Magnetic core/shell/shell triple structure material with noble metal nano particles being at double-shell interlayer and preparation method of material

A nanoparticle and triple structure technology is applied in the field of magnetic core/shell/shell triple structure materials and their preparation, which can solve the loss of metal, increase energy consumption and cost in the production process, and do not solve the problem of increasing the agglomeration of loaded nano metal particles. and other problems, to achieve the effect of preventing loss and agglomeration, and good magnetic responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

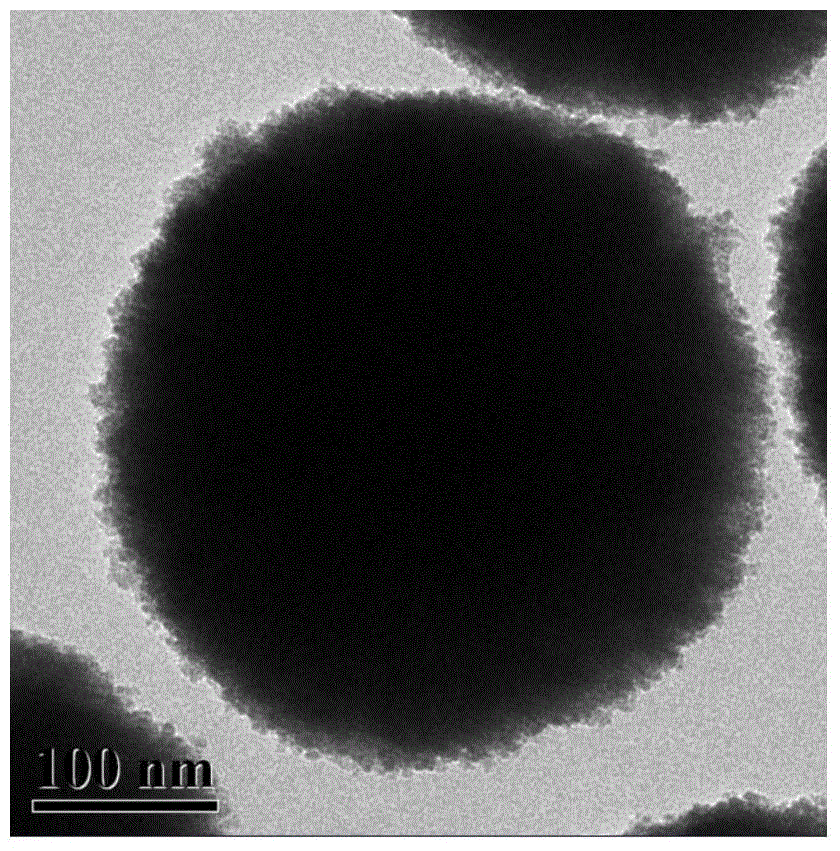

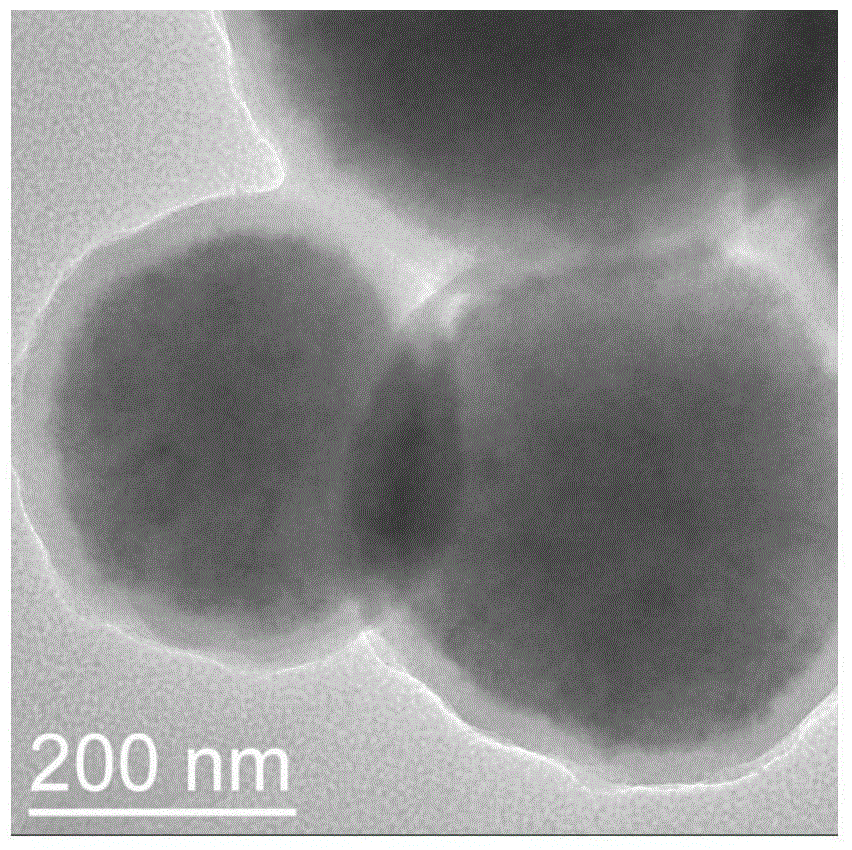

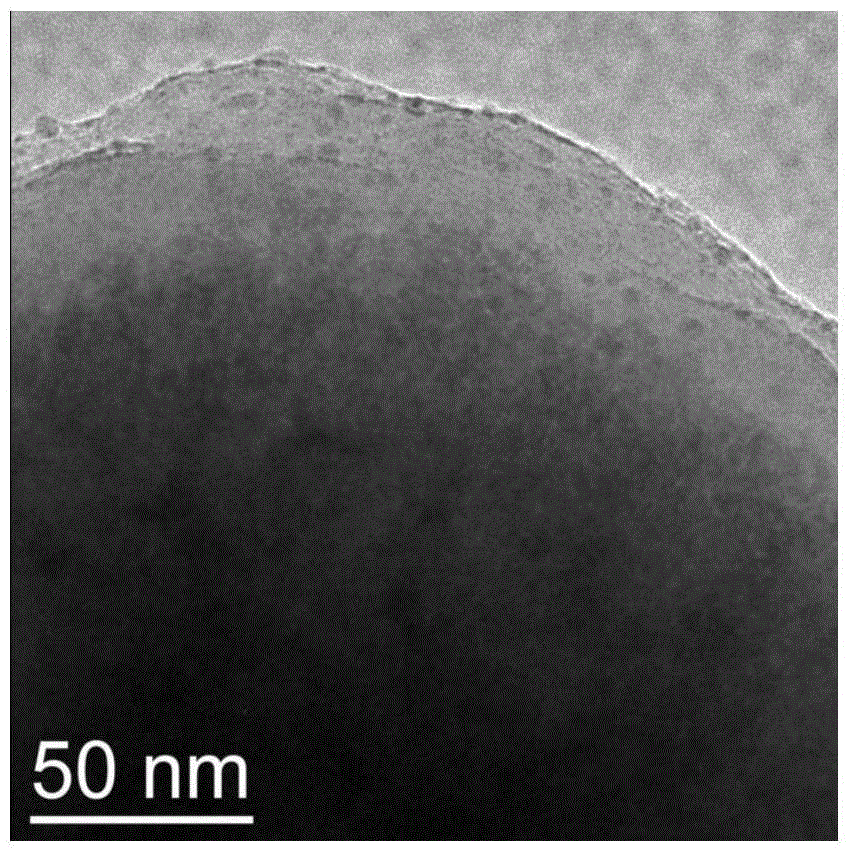

[0022] Fe 3 o 4 SiO 2 / PdZIF-8 synthesis:

[0023] (1) Add 1.35g of ferric chloride hexahydrate and 3.6g of sodium acetate into 40mL of ethylene glycol and stir for 1h to dissolve it, then put it into a synthesis kettle at 200°C for 8h, then wash with ethanol for 3 times; then take 0.1g of Got Fe 3 o 4 Add 60mL of ethanol, 1mL of water, 2mL of ammonia water (28%) and 160μL of tetraethyl orthosilicate to the mixed solution, stir at 40°C for 6h to obtain Fe 3 o 4 SiO 2 core-shell particles.

[0024] (2) Take 15mL of 2mM H 2 PdCl 4 Add 21 mL of water, 14 mL of ethanol and 0.0667 g of PVP to the mixture and reflux for 3 h to obtain PVP-Pd nanoparticles.

[0025] (3) Fe obtained from the above step (1) 3 o 4 SiO 2 Add 20mL of APTES ethanol solution with a concentration of 1% by mass to the core-shell particles and stir mechanically at 60°C for 8h, and then the treated Fe 3 o 4 SiO 2 Add 10 mL of the PVP-Pd nanoparticle solution with a mass percent concentration of 0...

Embodiment 2

[0028] Fe 3 o 4 SiO 2 / PtZIF-8 synthesis:

[0029] (1) 5 mL of K at a concentration of 10 mM 2 PtCl 4 Add the solution to a mixture of 12.5 mL of 0.4 M TTAB and 29.5 mL of water, stir for 15 minutes, add 3 mL of 0.5 M sodium borohydride aqueous solution, and continue stirring at 50 ° C for 15 h to obtain TTAB - Pt nanoparticles.

[0030] (2) the Fe processed with APTES prepared in Example 1 3 o 4 SiO 2 Add 10 mL of the TTAB-Pt solution with a mass percent concentration of 0.001% synthesized in the above step (1) to the core-shell particles, and stir at 60° C. for 1 h.

[0031] (3) Add the magnetic particles obtained in the above step (2) directly to a mixture of 0.16 g of zinc nitrate dihydrate, 0.4 g of 2-methylimidazole, and 20 mL of methanol, and stir at 30° C. for 4 h to obtain Fe 3 o 4 SiO 2 / PtZIF-8 core / shell / shell particles.

Embodiment 3

[0033] Fe 3 o 4 SiO 2 / AuZIF-8 synthesis:

[0034] (1) 5 mL of 38.8 mM sodium citrate aqueous solution was quickly added to 50 mL of 1 mM HAuCl 4 solution, and then stirred and refluxed for 15 minutes to obtain citrate-protected Au nanoparticles.

[0035] (2) the Fe processed with APTES prepared in Example 1 3 o 4 SiO 2 Add 10 mL of the Au nanoparticle solution with a mass percent concentration of 0.001% synthesized in the above step (1) to the particles, and stir at 60° C. for 1 h.

[0036] (3) Add the magnetic particles obtained in the above step (2) directly to a mixture of 0.16 g of zinc nitrate dihydrate, 0.4 g of 2-methylimidazole, and 20 mL of methanol, and stir at 30° C. for 4 h to obtain Fe 3 o 4 SiO 2 / AuZIF-8 core / shell / shell particles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com