Anti-aging MPP (modified polypropylene) electric tube

An anti-aging and electric power technology, which is applied in the field of anti-aging MPP power pipes, can solve the problems of aging resistance and heat resistance that cannot meet the needs of the society, low product dimensional stability, poor aging resistance and degradation performance, etc., to improve rigidity , size reduction, and the effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

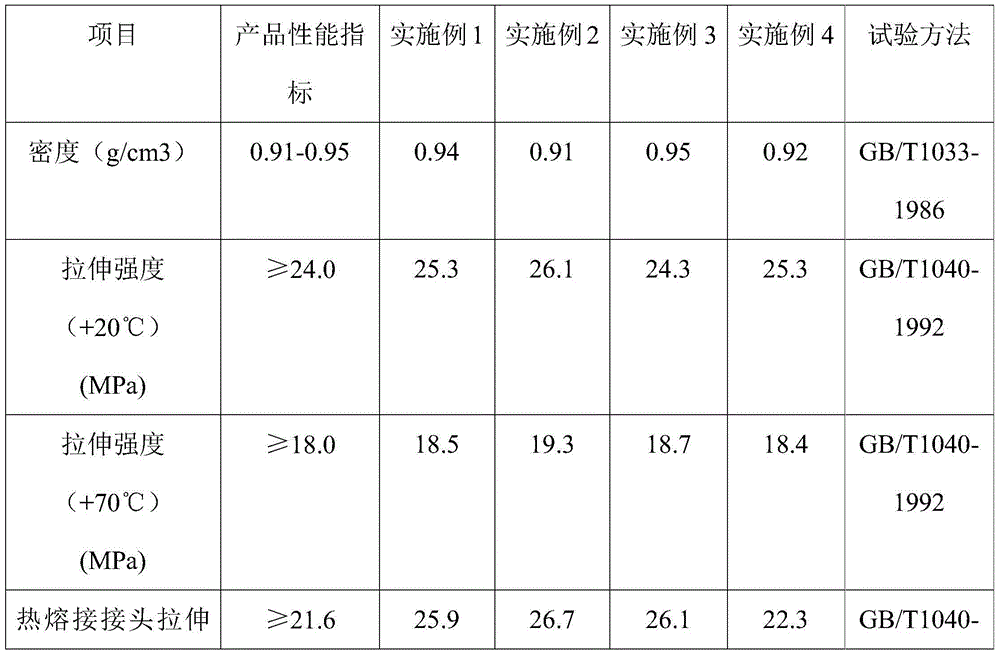

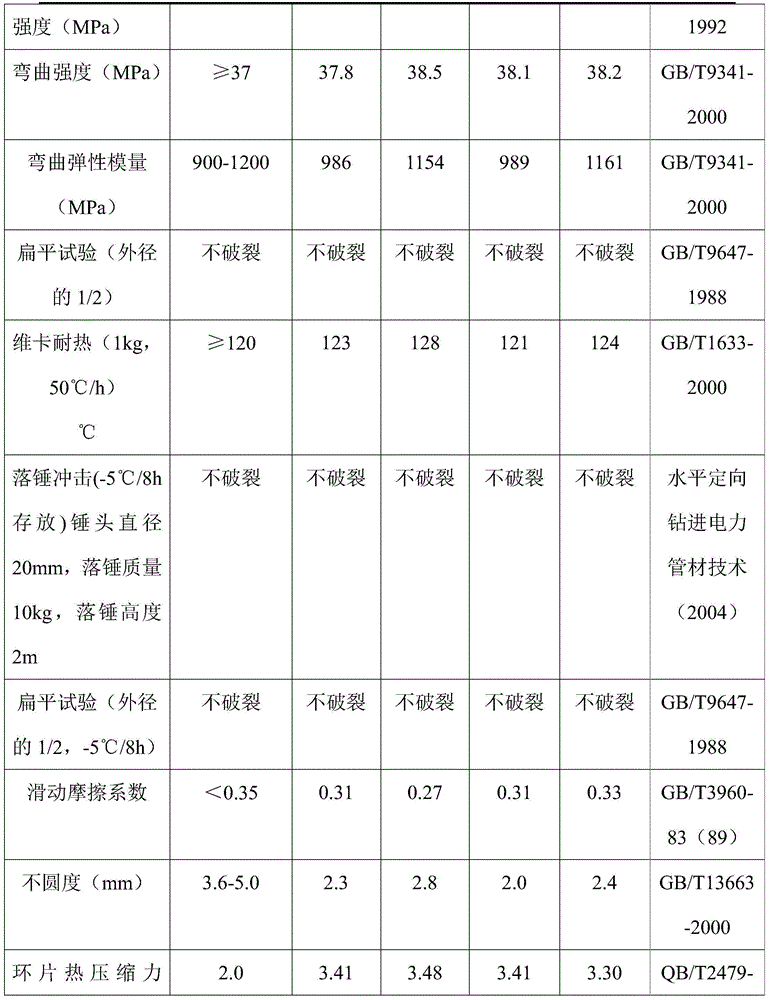

Examples

Embodiment 1

[0023] The anti-aging MPP electric power pipe of the present invention, its raw material comprises by weight: 125.4 parts of polypropylene, 7.5 parts of light calcium carbonate, 4.6 parts of flaky talcum powder, 4 parts of calcined kaolin, 1.3 parts of brucite powder, modified 26 parts of silica fume, 1.6 parts of coloring agent, 5.9 parts of new nucleating agent, 1.6 parts of antioxidant, 1.1 parts of polytetrafluoroethylene, 11 parts of toughening masterbatch, 9 parts of melamine cyanurate, 8 parts of modified whiskers ; The new nucleating agent is prepared by the following steps: add 153 parts of p-tert-butylbenzoic acid to 221ml tetraisopropyl titanate, react at 97°C for 3.5h, and then add 108ml orthosilicate formazan to obtain Solution A, solution A was added to ethanol-water mixture, hydrolyzed at 57°C for 3.6h, filtered and dried to obtain the new nucleating agent.

Embodiment 2

[0025] The anti-aging MPP power pipe of the present invention, its raw material comprises by weight: 128 parts of polypropylene, 7.6 parts of light calcium carbonate, 5 parts of flaky talcum powder, 5.5 parts of calcined kaolin, 2.8 parts of brucite powder, modified 29 parts of silica fume, 1.4 parts of coloring agent, 4.5 parts of new nucleating agent, 2.0 parts of antioxidant, 2.3 parts of polytetrafluoroethylene, 7 parts of toughening masterbatch, 16 parts of melamine cyanurate, 11.5 parts of modified whiskers ; Wherein, the modified microsilica powder is modified by a coupling agent, and the coupling agent is Si-42; the colorant is an organic colorant; the toughening masterbatch is mPE / LDPE crosslinking The modified whisker is a surfactant modified basic magnesium sulfate whisker, and the modification process is: add 10 parts of basic magnesium sulfate whisker and 150ml deionized water in a three-necked flask under stirring, and then add 0.5 parts of sodium dodecylbenzenes...

Embodiment 3

[0027] The anti-aging MPP power pipe of the present invention, its raw material comprises by weight: 105 parts of polypropylene, 8 parts of light calcium carbonate, 4.6 parts of flaky talcum powder, 4 parts of calcined kaolin, 3 parts of brucite powder, modified 36 parts of silica fume, 2.3 parts of coloring agent, 5 parts of new nucleating agent, 1.9 parts of antioxidant, 1.8 parts of polytetrafluoroethylene, 8 parts of toughening masterbatch, 12.9 parts of melamine cyanurate, 9 parts of modified whiskers ; Wherein, the modified micro-silica powder is modified with a coupling agent, the coupling agent is KH-550 and Si-42; the colorant is an inorganic colorant; the toughening masterbatch is mPE / LDPE cross-linked product; the modified whiskers are surfactant-modified basic magnesium sulfate whiskers, and the modification process is: add 15 parts of basic magnesium sulfate whiskers and 250ml deionized Water, then add 0.5 parts of sodium alkylarylsulfonate and 0.3 parts of sodiu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com