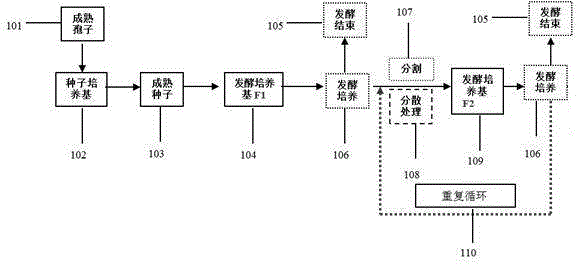

Method for producing citric acid by continuous fermentation of Aspergillus niger

A technology of Aspergillus niger and citric acid, applied in the field of fermentation engineering, can solve the problems of restricting the popularization and application of yeast, difficulty in the production process of citric acid, difficulty in separation and purification of citric acid, etc., to facilitate mass transfer and dissolved oxygen, shorten production cycle, The effect of reducing raw material cost and operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1: Glucose and soybean meal powder were used to prepare seed medium (total nitrogen 8%, total nitrogen 0.15%) and fermentation medium (F1: total sugar 15.2%, total nitrogen 0.08%; F2~F10: total sugar 15.2%, total nitrogen 0.25%); cultivate mature Aspergillus niger spores to inoculate the seed medium, and the concentration of the spore liquid after transplanting is 300,000 / ml; cultivate for 20h to obtain a mature seed liquid, and then transfer the fermentation medium with 20% inoculum After 48 hours of fermentation and cultivation, 1 / 3 of the fermented liquid was divided, and the remaining fermented liquid continued to be fermented in F1 after the division. When the concentration of reducing sugar in the fermentation medium was lower than 0.5%, the fermentation ended and citric acid was obtained. The separated fermented liquid is dispersed and processed by a disperser. After the treatment, the average diameter of the bacteria ball is 90um, and it is transferred to...

Embodiment 2

[0041] Example 2: Corn flour and deionized water are mixed uniformly in a batching tank at about 60°C at a ratio of 1:3, and calcium hydroxide is added to adjust the pH to 6.0, and high-temperature α-amylase is added at 25U / g corn flour, and after The second injection liquefaction, the iodine test is qualified (light brown), and the corn liquefaction mixture is obtained; 70% of the mixture is filtered through the plate frame to obtain the corn liquefaction clear liquid. The corn liquefaction mixed liquid and the clear liquid were mixed in a certain proportion to prepare seed medium (12% total sugar, add a certain amount of ammonium sulfate to adjust total nitrogen 0.25%) and fermentation medium (F1: 16% total sugar, 0.05% total nitrogen; F2~F10: total sugar 16%, total nitrogen 0.15%). Cultivate mature Aspergillus niger spores to inoculate the seed medium, and the concentration of the spore liquid after transplanting is 450,000 / ml; cultivate for 28 hours to obtain mature seed l...

Embodiment 3

[0044]Embodiment 3: Same as Embodiment 2, corn flour and water are mixed evenly according to a certain ratio, and the liquefied mixed liquid is obtained through secondary jet liquefaction, the liquefied liquid is mixed with water according to a certain ratio, and a certain proportion of ammonium sulfate is added to prepare the seed culture medium ( Total sugar 9.5%, 0.26%). Mix cassava flour and water at a ratio of 1:4 in a batching tank at about 60°C, add calcium hydroxide to adjust the pH to 5.8, add high-temperature α-amylase at 30 U / g cassava flour, and undergo secondary jet liquefaction to obtain Cassava liquefaction liquid; cassava liquefaction mixed liquid is all filtered through plate and frame to obtain cassava liquefaction clear liquid. Mix cassava liquefaction clear liquid with water according to a certain ratio, add a certain amount of corn flour liquefaction liquid, and prepare fermentation medium (F1: total sugar 14%, total nitrogen 0.15%; F2~F10: total sugar 14%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com