High conversion efficiency anti-pid crystalline silicon solar cell and manufacturing method thereof

A technology of solar cells and conversion efficiency, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the high requirements of equipment furnace tube cleanliness, the increase in the proportion of defective cell appearance, and the reduction in cell conversion efficiency, etc. It can eliminate the PID effect, improve the conversion efficiency, and improve the absorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

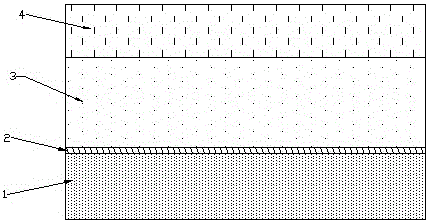

Image

Examples

Embodiment 1

[0024] Step 1, preheating, the silicon wafer enters the reaction chamber of the tubular coating equipment, and nitrogen and ammonia gas are introduced. The flow rate of nitrogen gas is 3000 sccm / min, and the flow rate of ammonia gas is 3000 sccm / min. Turn on the radio frequency power supply to carry out the treatment of graphite boat and silicon wafer. Heating, the RF power is 5800W, the pressure range is 1.0 is Torr, the time is 240sec, and the temperature is 410℃;

[0025] Step 2, silicon oxide film layer deposition, feed nitrous oxide gas, the gas flow rate is 5000sccm / min, the pressure is 1.0Torr, the deposition time is 160sec, and a layer of silicon oxide film with a thickness of 2-3nm is deposited on the surface of the silicon wafer Floor;

[0026] Step 3: Vacuumize and extract the reaction residual gas in the reaction chamber to prepare for the subsequent deposition of silicon nitride and silicon oxynitride;

[0027] Step 4, constant pressure, filling the reaction cham...

Embodiment 2

[0038] Step 1, preheating, the silicon wafer enters the reaction chamber of the tubular coating equipment, and nitrogen and ammonia gas are introduced. The flow rate of nitrogen gas is 3000 sccm / min, and the flow rate of ammonia gas is 3000 sccm / min. Turn on the radio frequency power supply to carry out the treatment of graphite boat and silicon wafer. Heating, the RF power is 5800W, the pressure range is 1.0 is Torr, the time is 240sec, and the temperature is 410℃;

[0039] Step 2, silicon oxide film layer deposition, feed nitrous oxide gas, the gas flow rate is 5000sccm / min, the pressure is 1.0Torr, the deposition time is 160sec, and a layer of silicon oxide film with a thickness of 2-3nm is deposited on the surface of the silicon wafer Floor;

[0040] Step 3: Vacuumize and extract the reaction residual gas in the reaction chamber to prepare for the subsequent deposition of silicon nitride and silicon oxynitride;

[0041] Step 4, constant pressure, filling the reaction cham...

Embodiment 3

[0052] In order to make the above-mentioned purpose, features and advantages of the present invention more obvious and easy to understand, the following solar cell coating process will give an example to describe in detail.

[0053] Step 1, preheating, the silicon wafer enters the reaction chamber of the tubular coating equipment, and nitrogen and ammonia gas are introduced. The flow rate of nitrogen gas is 3000 sccm / min, and the flow rate of ammonia gas is 3000 sccm / min. Turn on the radio frequency power supply to carry out the treatment of graphite boat and silicon wafer. Heating, the RF power is 5800W, the pressure range is 1.0 is Torr, the time is 240sec, and the temperature is 410℃;

[0054] Step 2, silicon oxide film layer deposition, feed nitrous oxide gas, the gas flow rate is 5000sccm / min, the pressure is 1.0Torr, the deposition time is 160sec, and a layer of silicon oxide film with a thickness of 2-3nm is deposited on the surface of the silicon wafer Floor;

[0055]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com