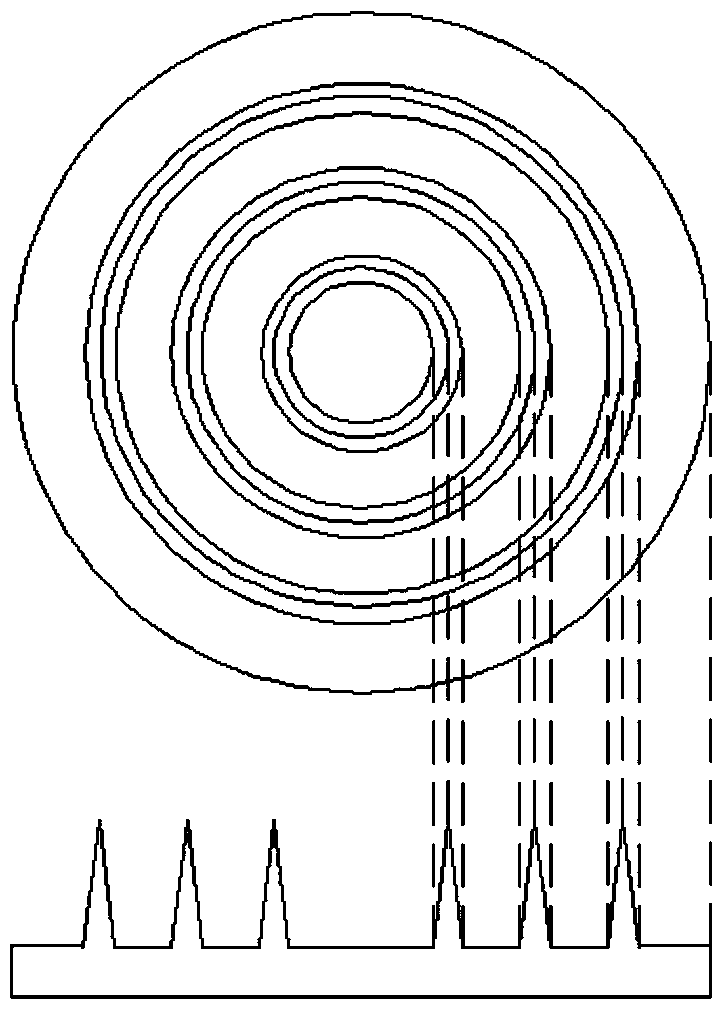

Polycrystal hexaboride annular field emission cathode and preparation method thereof

A field emission cathode and hexaboride technology, which is applied in the manufacture of cold cathodes, electrode systems, discharge tubes/lamps, etc., can solve problems such as the instability of the cathode cone structure, achieve excellent electron emission performance, and avoid contact Not strong, the effect of large effective field emission area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

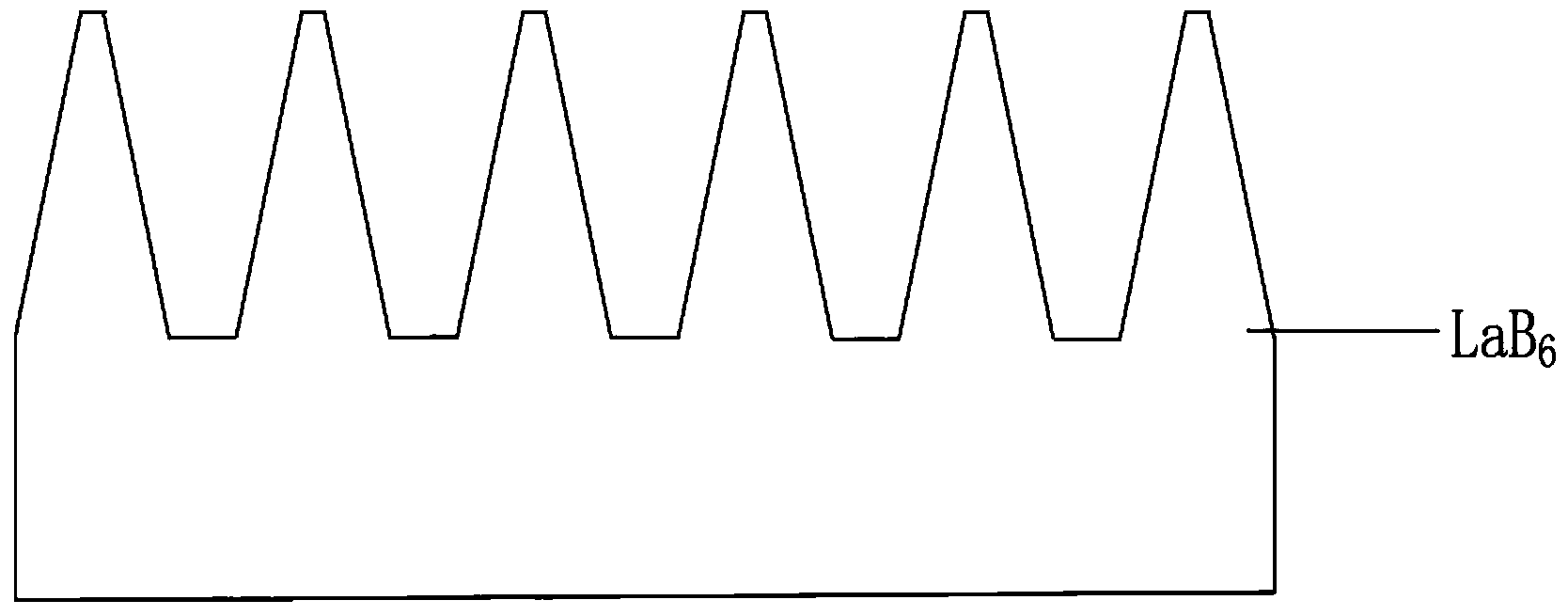

[0033] In this example, an amorphous silicon film is used as a mask for polycrystalline lanthanum hexaboride etching to prepare a large-area polycrystalline lanthanum hexaboride field emission cathode. The steps are as follows:

[0034] 1) Polishing and cleaning: After polishing the polycrystalline lanthanum hexaboride substrate, ultrasonically clean it with detergent, deionized water, absolute ethanol, acetone, absolute alcohol, and deionized water in sequence. The cleaning time is 15 minutes.

[0035] Because the surface of the processed polycrystalline lanthanum hexaboride substrate is not smooth enough, it needs to be ground and polished with emery abrasives. Then use different reagents to clean and remove particles, metal ions and organic impurities attached to the surface of the substrate in order to obtain a clean surface. The cleaned substrates were blown dry with nitrogen.

[0036] 2) Mask deposition: the plasma-enhanced chemical vapor deposition (PECVD) method is u...

Embodiment 2

[0049] In this example, a method for preparing a large-area polycrystalline lanthanum hexaboride field emission cathode using a silicon nitride film as a mask for polycrystalline lanthanum hexaboride etching, the steps are as follows:

[0050] 1) Polishing and cleaning: After polishing the polycrystalline lanthanum hexaboride substrate, ultrasonically clean it with detergent, deionized water, absolute ethanol, acetone, absolute alcohol, and deionized water in sequence. The cleaning time is 15 minutes.

[0051] 2) Mask deposition: Deposit silicon nitride (Si 3 N 4 ) film as a mask for bulk polycrystalline lanthanum hexaboride etching. Among them, silicon nitride (Si 3 N 4 ) mask deposition parameters: SiH 4 with NH 3 The flow ratio is 3sccm:50sccm, the pressure is 60Pa, the power is 15W, the substrate temperature is 250°C, the gas temperature is 160°C, and the deposition time is 30min.

[0052] 3) Glue coating: uniformly coat a layer of positive photoresist on the above-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com