Anti-fatigue cable material and preparation method thereof

A cable material and anti-fatigue technology, applied in the field of anti-fatigue cable material and its preparation, can solve the problems of poor fatigue resistance, insufficient toughness, electric shock, etc., and achieve good oil resistance, excellent fatigue resistance, and good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

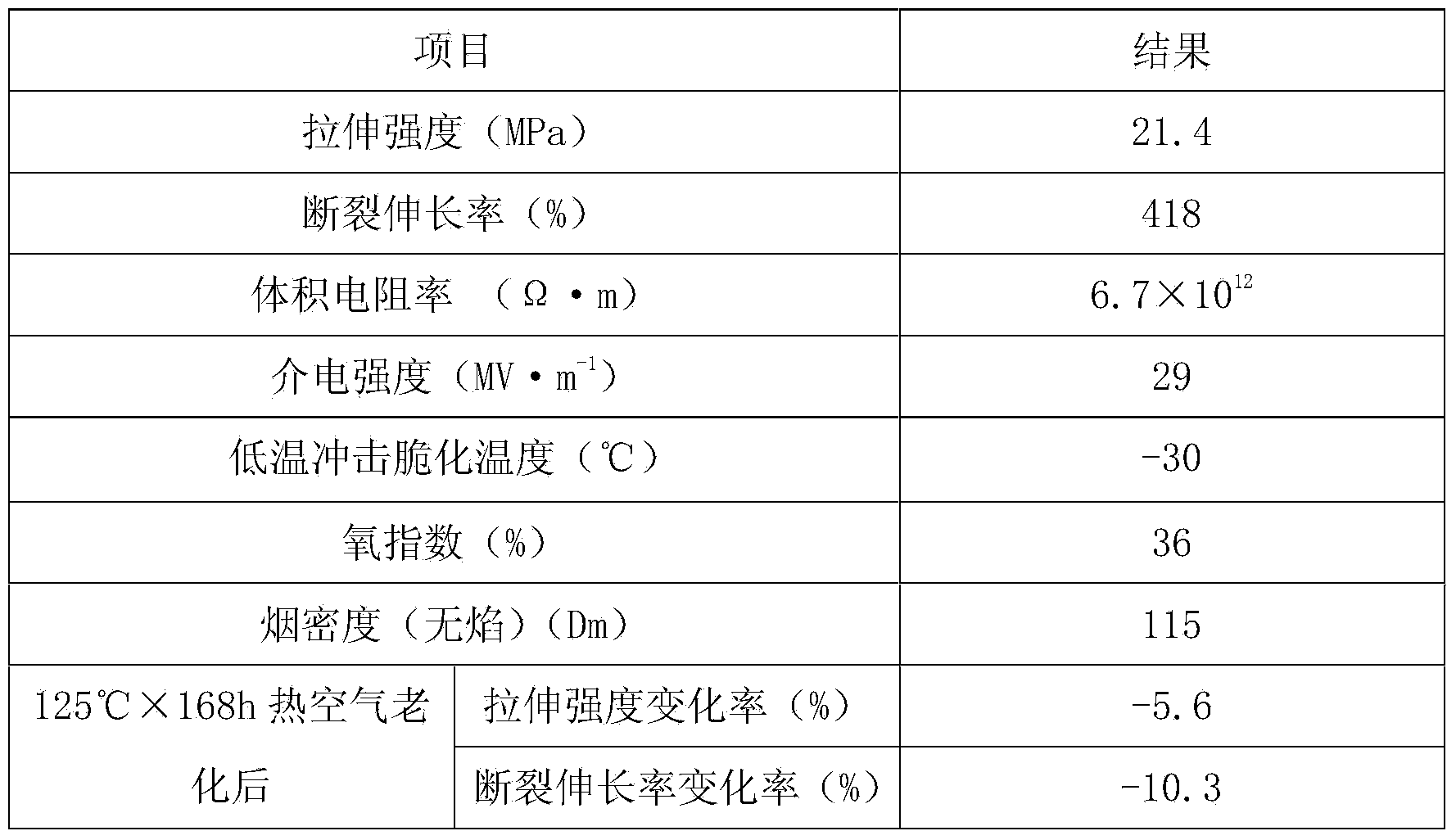

Examples

Embodiment Construction

[0013] An anti-fatigue cable material, made of the following raw materials by weight (kg): SG-5 type polyvinyl chloride 80, impact-resistant polystyrene 20, polyether ether ketone 15, epoxy soybean oil 8, trioxide Antimony 12, activated aluminum hydroxide 1-, nano bauxite 18, glass fiber 6, composite filler 7, trioctyl trimellitate 12, acetyl tributyl citrate 8, dioctyl phthalate 6, Calcium-zinc composite stabilizer 2, tributyltin chloride 1.5, isopropyl tris (dioctyl pyrophosphate acyloxy) titanate 0.8, erucamide 0.5, oxidized polyethylene wax 0.8;

[0014] The preparation method of described composite filler is as follows: a. get the raw material of following weight (kg): kaolinite 15, pyrophyllite 5, zeolite powder 6, fly ash 5, stearic acid 2, isopropyl distearyl oxygen Base aluminate 1, calcium lignosulfonate 3, epoxy linseed oil 10, nano zirconia 3, nano jade powder 5, cerium isooctanoate 1, neodymium isooctanoate 0.5; b, put kaolinite and pyrophyllite at 520°C Calcined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com