Preparation method of solvent-type polystyrene modified asphalt waterproof paint

A technology for modifying asphalt and polystyrene, which is applied in asphalt coatings, coatings, etc., can solve the problems of high toxicity of tar gas, short construction period, poor environmental protection, etc., and achieves convenient and simple preparation, low equipment investment, and good use effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

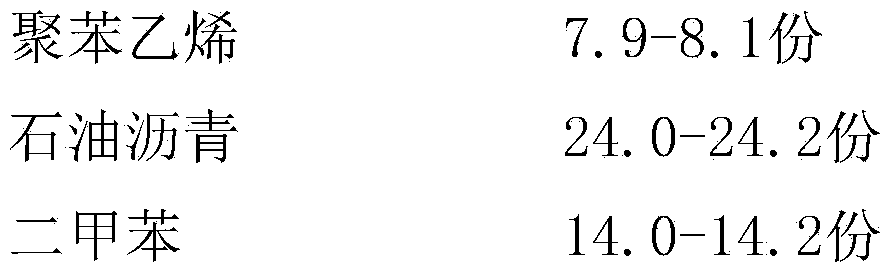

[0021] A solvent-based polystyrene modified asphalt waterproof coating is composed of the raw materials of the following components:

[0022]

[0023] The method for preparing solvent-based polystyrene modified asphalt waterproof coating of the present invention comprises the following processing steps:

[0024] a. Choose a mixing tank, pour the xylene and dichloropropane in the raw material into the mixing tank according to the formula amount and mix evenly, then put the polystyrene in the raw material into it, start stirring until it is completely dissolved and then set aside.

[0025] b. Select a heating and dissolving kettle, put the petroleum pitch in the raw material into it according to the formula amount, start heating until the temperature is 130-150°C, and start dehydration.

[0026] c. After the dehydration of the reactants in the dissolution kettle in step b is completed, all the rosin water, dibutyl phthalate, dioctyl phthalate, cresol and large white powder in...

Embodiment 2

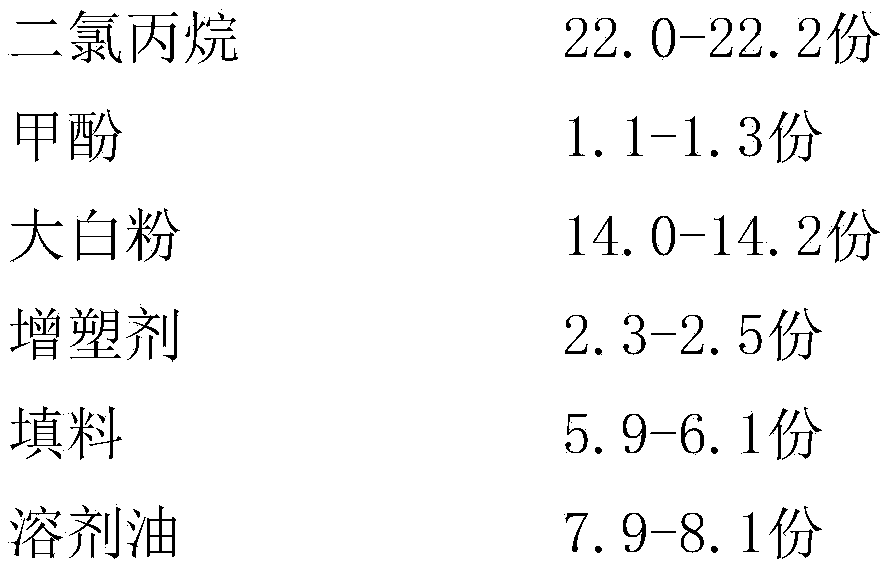

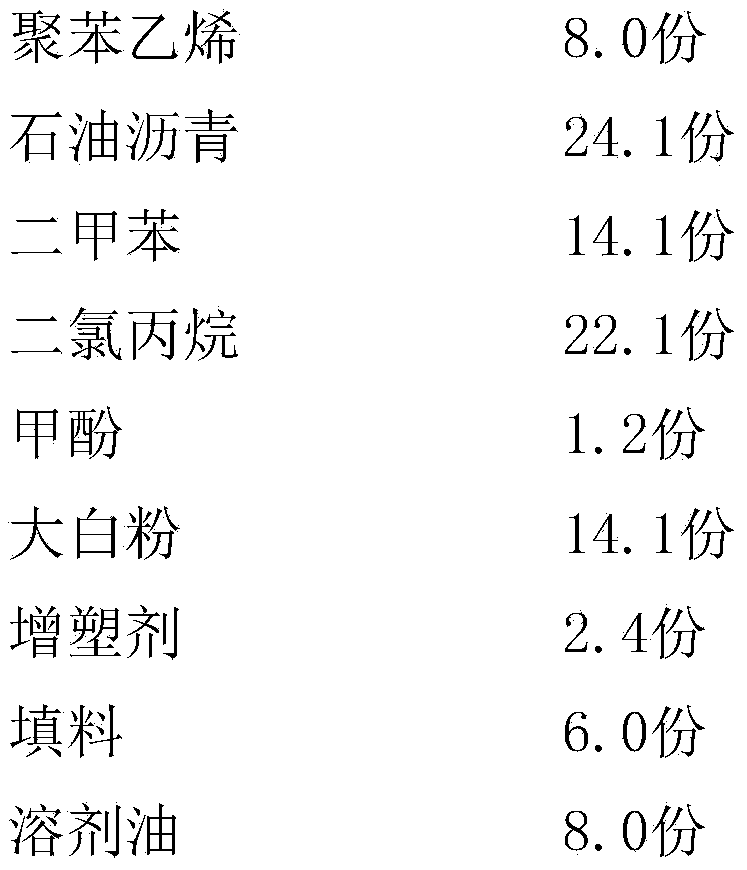

[0029] A solvent-based polystyrene modified asphalt waterproof coating is composed of the raw materials of the following components:

[0030]

[0031] The method for preparing solvent-based polystyrene modified asphalt waterproof coating of the present invention comprises the following processing steps:

[0032] a. Choose a mixing tank, pour the xylene and dichloropropane in the raw material into the mixing tank according to the formula amount and mix evenly, then put the polystyrene in the raw material into it, start stirring until it is completely dissolved and then set aside.

[0033] b. Select a heating and dissolving kettle, put the petroleum pitch in the raw material into it according to the formula amount, start heating until the temperature is 130-150°C, and start dehydration.

[0034] c. After the dehydration of the reactants in the dissolution kettle in step b is completed, all the rosin water, dibutyl phthalate, dioctyl phthalate, cresol and large white powder in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com