Technology for smelting difficultly-treated precious metal-containing material

A precious metal and refractory technology, which is applied in the field of smelting process of precious metals and refractory precious metal-containing materials, can solve the problem of high investment and achieve the effect of less investment, strong adaptability and low melting point of lead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

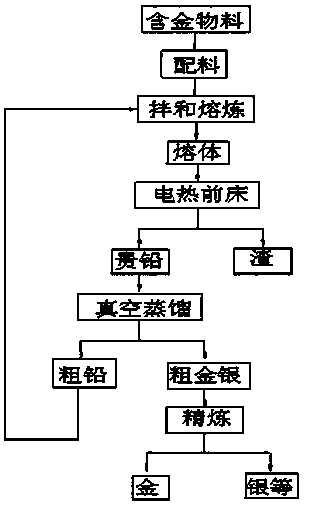

[0023] like figure 1 As shown, for a gold-containing material - cyanide slag, containing 12g / t gold and 30 g / t silver, the main impurities are iron oxide, silicon dioxide, calcium oxide, etc., through phase analysis , the slag type is close to the blast furnace lead slag type, the material contains 1.5% arsenic and 0.5% antimony, and its smelting process includes the following steps

[0024] Step (1): Put the precious metal-containing material into the furnace from the feeding port of the side blowing smelting furnace at the bottom, and at the same time add 15% of the mass of the precious metal-containing material lead, and smelt it under a weak reducing atmosphere at 900°C for 60 minutes to make the gold and silver in the material The precious metals are enriched in the lead liquid to obtain the melt;

[0025] Step (2): discharge the melt obtained in step (1) from the bottom of the melting furnace to the discharge port of the side blowing melting furnace into the electric he...

Embodiment 2

[0030] like figure 1 As shown, for a high-arsenic and high-sulfur refractory gold concentrate, the gold content is about 18g / t, the sulfur content is about 30%, and the arsenic content is about 10%. Its smelting process includes the following steps:

[0031] First, the conventional two-stage roasting process is used to desulfurize and dearsenate;

[0032] Step (1), put the high-temperature roasted ore roasted in the second stage directly into the rotary kiln for smelting, and at the same time add the lead in the lead anode slime containing 15% of the mass of the precious metal material, and smelt it under a weak reducing atmosphere at a smelting temperature of 1200°C 90min, so that precious metals such as gold and silver in the material are enriched in the lead liquid to obtain a melt;

[0033] Step (2): discharge the melt obtained in step (1) from the discharge port of the rotary kiln into the electric heating front bed, heat up to 1300°C, and then stand and separate for 60...

Embodiment 3

[0038] like figure 1 As shown, for a high-arsenic and high-sulfur refractory gold concentrate, the gold content is about 18g / t, the sulfur content is about 30%, and the arsenic content is about 10%. Its smelting process includes the following steps:

[0039] First, the conventional two-stage roasting process is used to desulfurize and dearsenize the raw materials;

[0040] In step (1), the high-temperature roasted ore roasted in the second stage is directly put into the rotary kiln for smelting, and at the same time, metal lead containing 10% of the mass of the precious metal material is added, and the smelting temperature is 1100°C under a weak reducing atmosphere for 45 minutes to make the material Precious metals such as gold and silver are enriched in the lead liquid to obtain a melt;

[0041] Step (2): discharge the melt obtained in step (1) from the discharge port of the rotary kiln into the electric heating front bed, heat up to 1200°C, and then stand and separate for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com