Method for preparing nitrogen-doped titanium dioxide photocatalyst through electron beam irradiation

A technology of electron beam irradiation and titanium dioxide, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, catalyst activation/preparation, etc., can solve the problems of high cost, long preparation time, complicated process, etc., and achieve good crystallization and low cost. The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

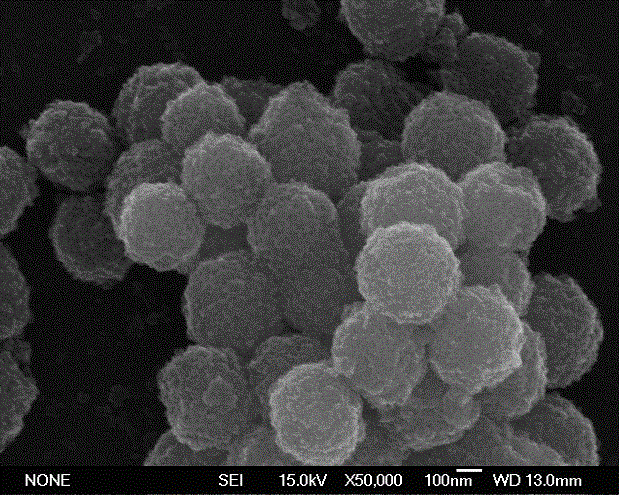

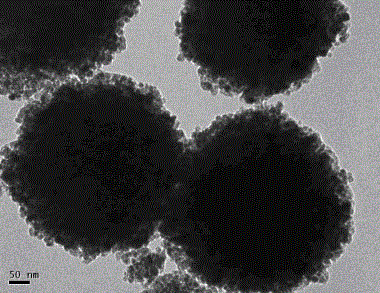

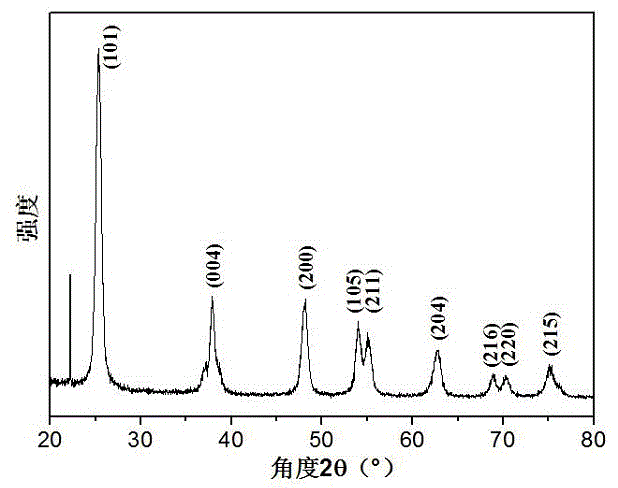

[0019] First, prepare titanium dioxide according to the existing known technology (for this technical method, please refer to the literature: Chem. Commun., 2012, 18, 4250-4252.)

[0020] 1. Preparation of titanium dioxide

[0021] A certain amount of octadecylamine (C 18 h 39 N) Add to absolute ethanol, then add deionized water, and mix uniformly at room temperature to obtain solution A. In addition, a certain amount of tetra-n-butyl titanate (C 16 h 36 o 4 Ti) was added into absolute ethanol, and ultrasonically mixed to obtain solution B. Mix solution B and solution A evenly, transfer to the reaction kettle, 170 o C for 20 hours; after the reaction, the reaction solution was naturally cooled to room temperature; then centrifuged to obtain a solid sample; then the sample was repeatedly washed with absolute ethanol and deionized water. Wash the samples at 60 o C under vacuum. Finally, dry the sample at 350 o C and calcined for 3 hours to obtain titanium dioxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com