Wastewater treatment and reuse device and process for treating wastewater

A waste water treatment, waste water technology, applied in the direction of water/sewage multi-stage treatment, water/sludge/sewage treatment, dispersed particle separation, etc., can solve the problems of high operating cost, large investment cost, and the introduction of other impurity ions, etc., to achieve The effect of low running cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

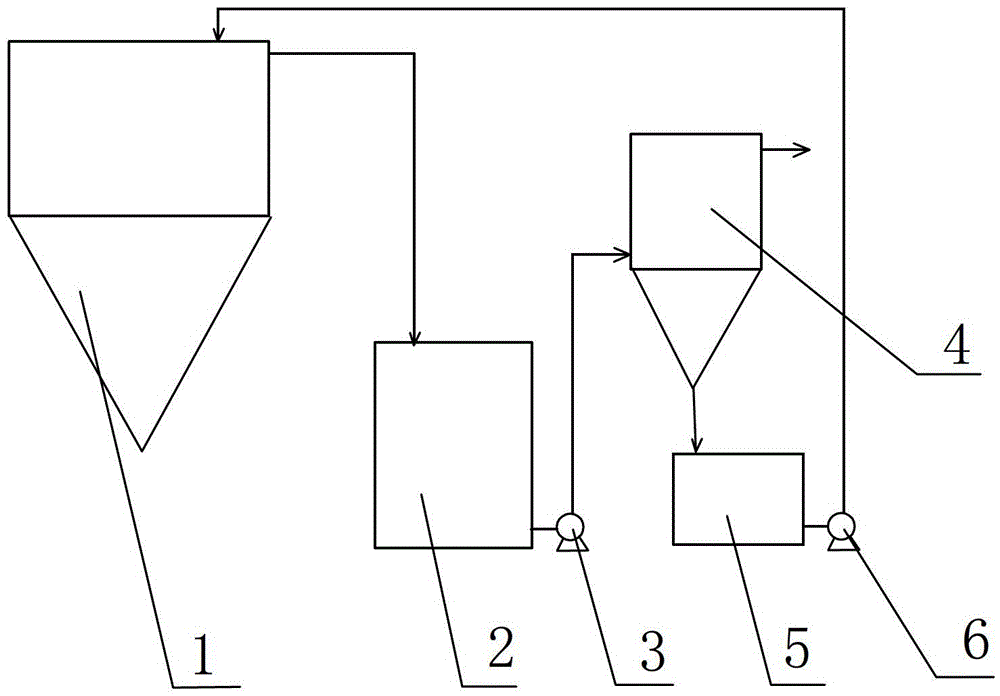

[0034] The wastewater treatment and reuse device of the present invention is as attached figure 1 As shown, it includes a dewatering bin 1 for holding waste water, a regulating pool 2 connected to the water outlet of the dewatering bin 1, a primary filter 4, and a slag pool 5 connected to the bottom of the primary filter 4, which is used to dewater the The waste water in the conditioning tank 2 is pumped to the primary filter feed pump 3 in the primary filter 4 and the slurry transport pump 6 that transports the slurry in the slag tank 5 to the dewatering bin 1. The slurry transport pump 6 and the dewatering bin 1 connect. The adjustment tank is a pH adjustment tank, and the pH value is adjusted by adding lime slurry. The primary filter 4 is an automatic backwashing surface filter.

[0035] This embodiment mainly removes the suspended solids in the ash flushing wastewater. The technological process is as follows: the ash flushing wastewater first enters the dehydration bin f...

Embodiment 2

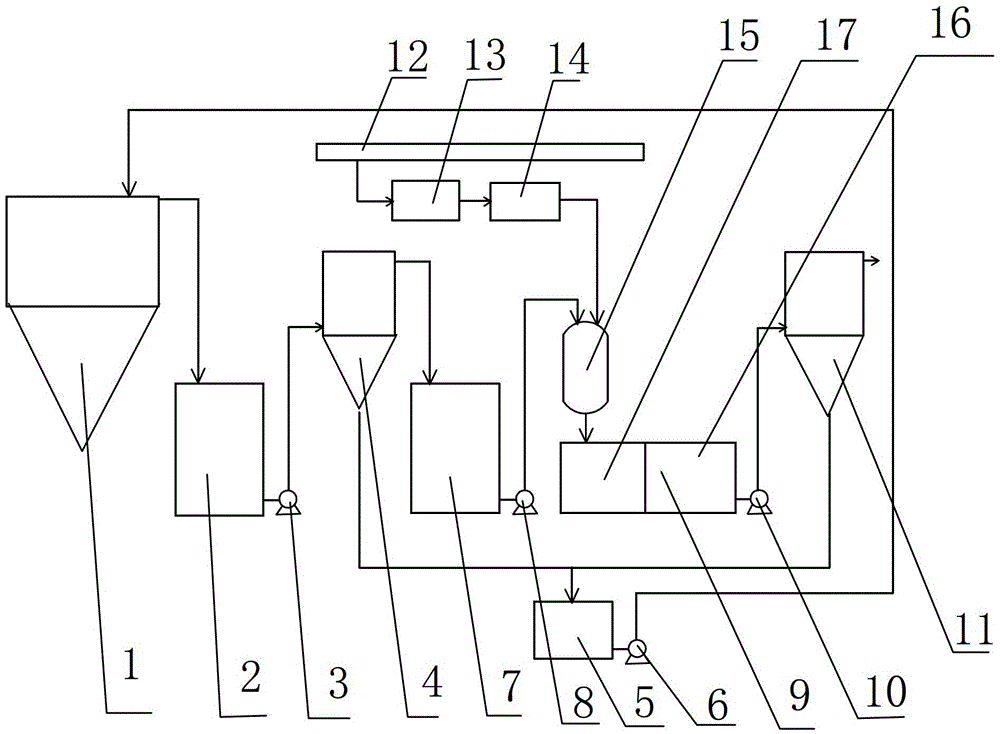

[0040] The wastewater treatment and reuse device of the present invention is as attached figure 2 As shown, it includes a dehydration bin 1 for holding waste water, a regulating tank 2 connected to the water outlet of the dehydration bin 1, a primary filter 4, a secondary filter 11, and a connection between the primary filter 4 and the secondary filter 11. The slag pool 5 connected at the bottom, the primary filter feed pump 3 for pumping the waste water in the conditioning pool 2 into the primary filter 4, and the slurry transfer pump 6 for transporting the slurry in the slag pool 5 to the dewatering bin 1 , the slurry pump 6 is connected to the dewatering bin 1 . The adjustment tank 2 is a pH adjustment tank, and the primary filter 4 is an automatic backwashing surface filter.

[0041]It also includes a buffer pool 7, a gas-liquid mixer 15 connected to the clear liquid port of the primary filter 4, a raw water delivery pump 8 that sends the liquid in the buffer pool 7 to t...

Embodiment 3

[0046] This embodiment is an extended application of Embodiment 2. The treatment device is the same as that of Embodiment 2. It is mainly based on the fact that the water quality of chemical water treatment wastewater produced by thermal power plants is basically the same as that of ash flushing wastewater, and its water volume is not very large. It can be used as a supplement to the lost water during ash flushing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com