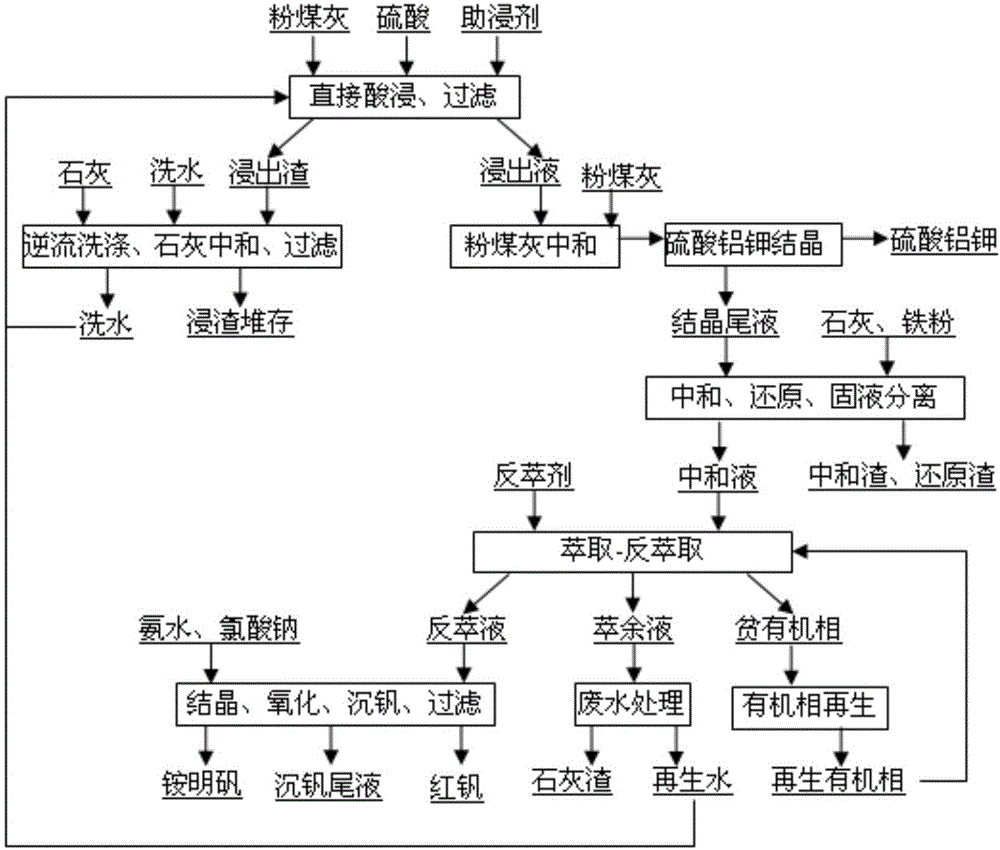

Technological method for comprehensively recovering vanadium and potassium through acid leaching of pulverized fuel ash

A technology of fly ash and acid leaching, which is applied in the field of hydrometallurgy, can solve the problems of large waste of resources, low recovery rate, and high cost, and achieve the effects of increasing profit margins, increasing recovery rate, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] This method was used to collect fly ash from a certain place in Shaanxi. The main minerals of the mine are quartz and clay minerals, V 2 o 5 Content 0.92%. The fly ash is the fly ash after combustion of vanadium-containing stone coal mines with a low calorific value below 3500 kcal or stone coal vanadium mines with a low calorific value below 2000 kcal.

[0032] (1) Leaching-fly ash neutralization operation

[0033] Add 40% sulfuric acid of fly ash and 3.50% leaching aid calcium fluoride, liquid-solid ratio (ratio of leaching liquid volume to solid weight) 2.5:1, and leaching reaction at 90°C for 7 hours. After the leaching operation is completed, solid-liquid separation is carried out, and the leaching supernatant is neutralized with fly ash, the amount of which is 55% of the amount of leached fly ash, the neutralization temperature of fly ash is 50°C, and the neutralization time is 4 hours. Solid-liquid separation is smooth. Neutralizing solution contains V 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com