Preparation method for hydrotalcite-carbon paper composite material and application of hydrotalcite-carbon paper composite material as biosensor

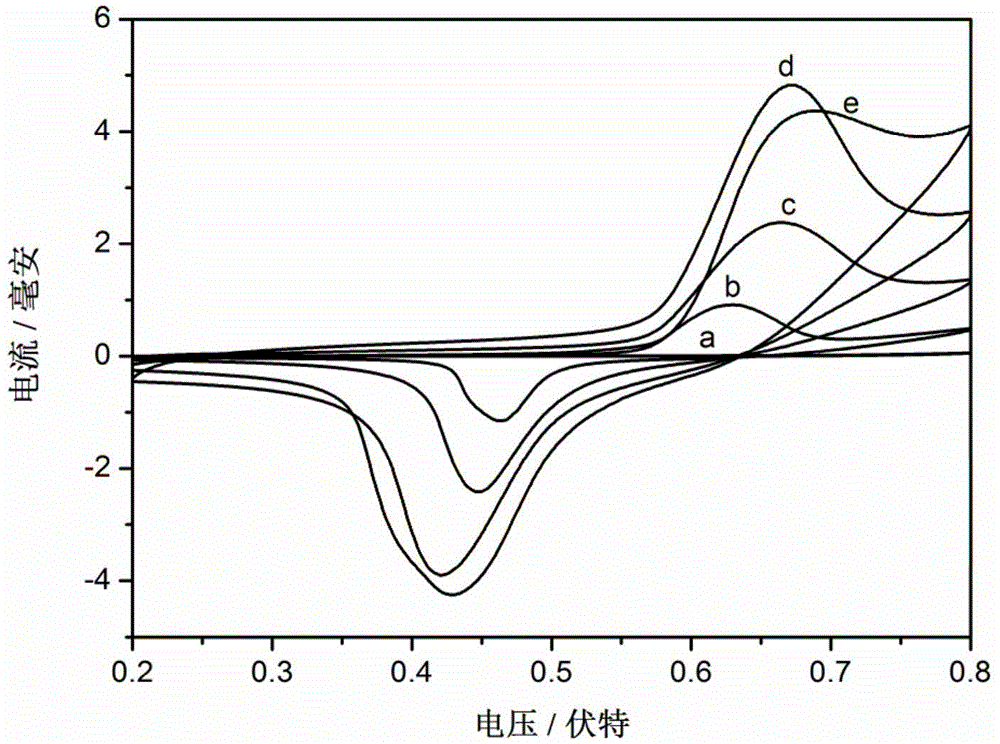

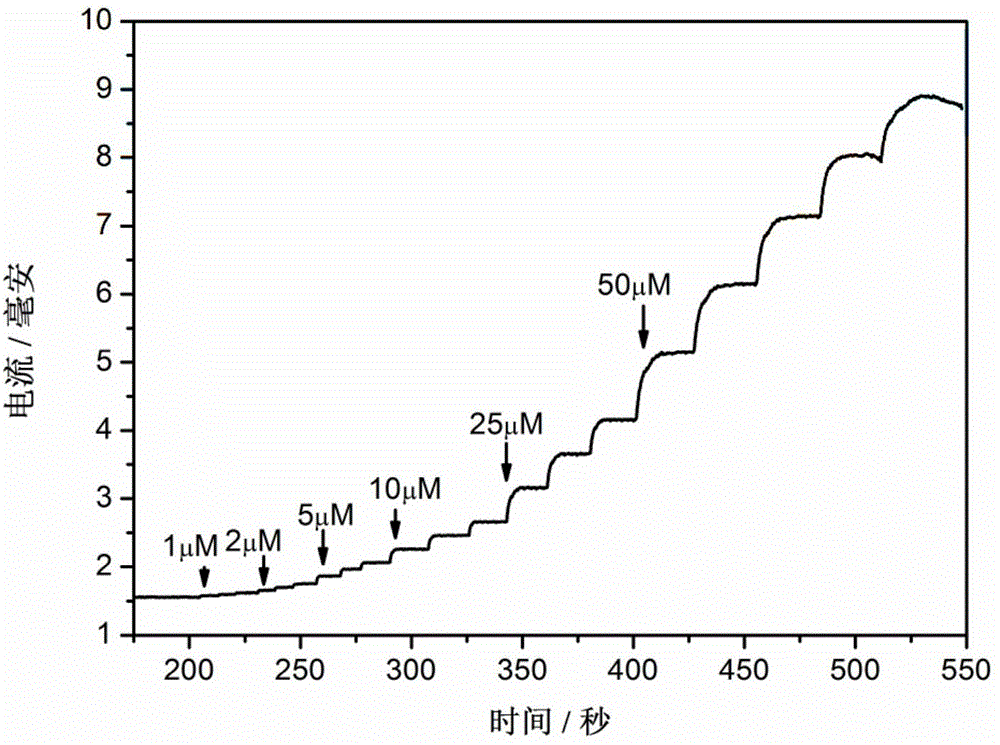

A technology of composite materials and hydrotalcite, which is applied in the field of electrochemical biosensor preparation, can solve the problems of medium-level electrocatalytic performance of composite electrodes, and achieve the effects of good electrocatalytic performance, wide linear range and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

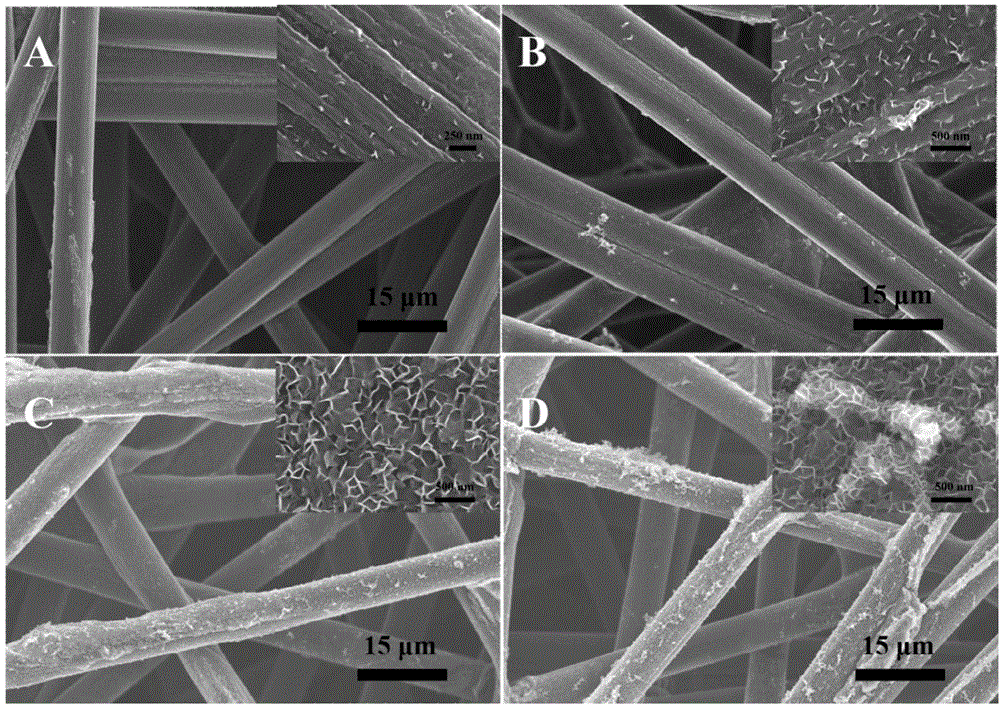

[0031] A. Preparation of AlOOH colloidal solution: Dissolve aluminum isopropoxide in deionized water at a mass ratio of aluminum isopropoxide to deionized water of 1 / 10, stir at 85°C for 20 minutes; use 1mol / L HNO 3 The pH of the aqueous solution was adjusted to 3.4, stirred at 85°C for 2 hours, and then dried at 60°C to obtain solid AlOOH, which was ground into powder; dissolved according to the mass ratio of AlOOH to deionized water of 1 / 18, stirred at 85°C for 60 Minutes, then add 1mol / L HNO dropwise 3 aqueous solution, adjust the pH to 2.5 to obtain a milky white translucent AlOOH colloidal solution;

[0032] B. Preparation of reaction bottom liquid: according to Ni(NO 3 ) 2 ·6H 2 O and NH 4 NO 3 Ni(NO 3 ) 2 ·6H 2 O and NH 4 NO 3 Soluble in deionized water, NH 4 NO 3 The concentration is 2mol / L; finally adjust the pH to 5.9 with 1mol / L ammonia water to obtain the reaction bottom solution;

[0033] C. Preparation of hydrotalcite carbon paper composite material: 1...

Embodiment 2

[0041] The preparation of A.AlOOH colloidal solution is with embodiment 1;

[0042] B. Preparation of reaction bottom liquid: according to Co(NO 3 ) 2 ·6H 2 O and NH 4 NO 3 Co(NO 3 ) 2 ·6H 2 O and NH 4 NO 3 Soluble in deionized water, NH 4 NO 3 The concentration is 2mol / L; finally adjust the pH to 6.0 with 1mol / L ammonia water to obtain the reaction bottom liquid;

[0043] C. Preparation of hydrotalcite carbon paper composite material: 1) immerse the carbon paper in ethanol, acetone, and secondary water for 20 minutes, and then dry it naturally at room temperature; 2) then immerse the carbon paper in the AlOOH colloidal solution , take it out after 10 minutes, dry it with N2, and complete the deposition of one layer of AlOOH; 3) repeat step 2) to operate 20 times, and deposit AlOOH thin layers of different thicknesses on the surface of carbon paper; 4) deposit the carbon of AlOOH thin layer on the surface The paper is immersed in the reaction bottom solution, seale...

Embodiment 3

[0047] A. Preparation of AlOOH colloidal solution: Dissolve aluminum isopropoxide in deionized water at a mass ratio of aluminum isopropoxide to deionized water of 1 / 9, stir at 80°C for 30 minutes; use 1mol / L HNO 3 The pH of the aqueous solution was adjusted to 3.7, stirred at 80°C for 3 hours, and then dried at 50°C to obtain solid AlOOH, which was ground into powder; dissolved according to the mass ratio of AlOOH to deionized water of 1 / 17, stirred at 85°C for 100 Minutes, then add 1mol / L HNO dropwise 3 aqueous solution, adjust the pH to 2 to obtain a milky white translucent AlOOH colloidal solution;

[0048] B. Preparation of reaction bottom liquid: according to Ni(NO 3 ) 2 ·6H 2 O and NH 4 NO 3 Ni(NO 3 ) 2 ·6H 2 O and NH 4 NO 3 Soluble in deionized water, NH 4 NO 3 The concentration is 2.3mol / L; finally adjust the pH to 5.9 with 1mol / L ammonia water to obtain the reaction bottom liquid;

[0049]C. Preparation of hydrotalcite carbon paper composite material: 1)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com