Method for preparing graphene/epoxy resin composite

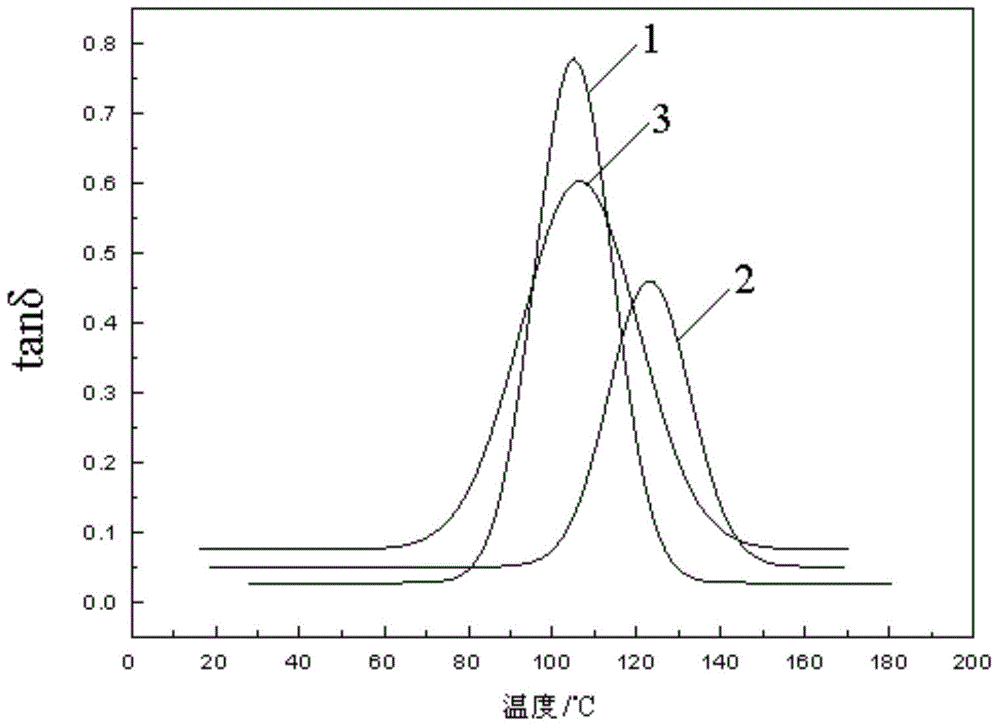

A technology of epoxy resin and composite materials, which is applied in the field of preparation of epoxy resin composite materials, can solve the problems of high brittleness, poor impact resistance, cracking and other problems of epoxy resin, and achieve the improvement of glass transition temperature, simple method and dispersion effect Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0025] Specific embodiment one: present embodiment is a kind of preparation method of graphene / epoxy resin composite material, specifically is finished according to the following steps:

[0026] 1. Preparation of graphene by chemical oxidation method: 1. Add flake graphite powder into the container, then add concentrated sulfuric acid with a mass fraction of 90% to 98% in the container, put the container into an ice-water bath, and stir at a stirring speed Stir for 30min to 60min under the condition of 250r / min~300r / min; then add potassium permanganate and sodium nitrate respectively under the condition of stirring speed of 150r / min~200r / min, and then React for 2h~3h under the condition of 200 / min; then react for 2h~4h under the condition of room temperature and stirring speed of 150r / min~200r / min; Add hydrogen peroxide with a mass fraction of 30% to 35% into the container to obtain a viscous solution;

[0027] The mass and mass fraction of the flaky graphite powder described...

specific Embodiment approach 2

[0043] Embodiment 2: This embodiment differs from Embodiment 1 in that the epoxy resin described in Step 2 is Epoxy Resin E-51, Epoxy Resin E-44 or Epoxy Resin E-42. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0044] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is: the specific operation steps of the method for the two-phase extraction described in step 2 are: first the graphene / ethanol mixed solution is added to the epoxy resin , and then stirred until the ethanol solution in the graphene / ethanol mixed solution changed from brownish yellow to colorless, then stopped stirring, and then removed the upper ethanol solution to complete the two-phase extraction. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com