Conductive epoxy resin for pipeline repair and pipeline online repair method

A conductive resin, pipeline repair technology, applied in the direction of pipes/pipe joints/fittings, pipe components, mechanical equipment, etc., can solve the problems of internal defects, pipeline introduction, and low pressure bearing capacity of resin materials that cannot be fundamentally solved. Good field application effect, avoid corrosion, practical and simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

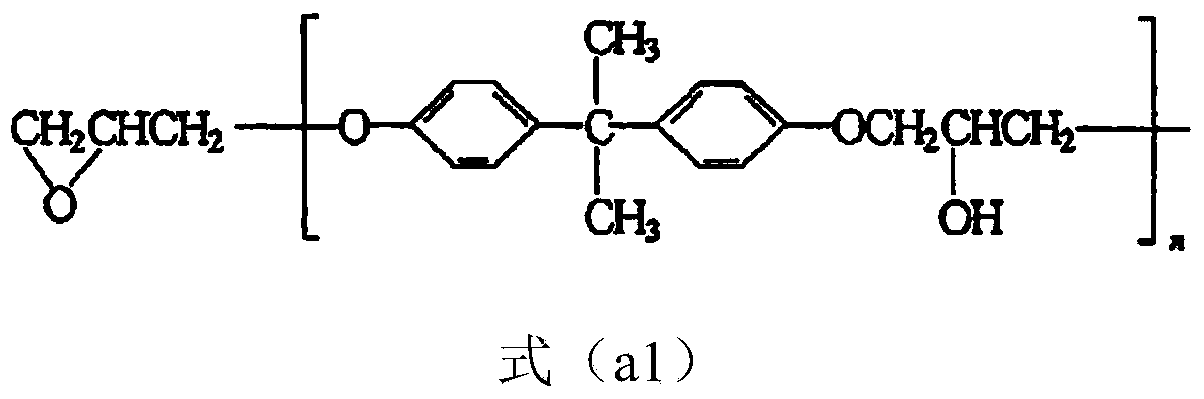

[0038] (1) Add liquid E-44 epoxy resin, liquid polyurethane, dimethyl phthalate and copper powder with a particle size of 80 microns into the vacuum dispersion at the mass percentage of 70%, 5%, 5%, and 20% In the reactor, stir at 500 rpm for 20 minutes at 30°C;

[0039] (2) The MGAZ63B sacrificial anode is processed into a powder with a particle size of 100 microns by a vacuum ball mill, and the powder and ethylenediamine are mixed according to a mass ratio of 1:1 and poured into a vacuum dispersion reactor at 30°C at 500 revolutions per minute. Stir at the speed of 10 minutes;

[0040] (3) Stir the mixture in (1) and (2) above in a vacuum reactor at a mass ratio of 6:1 at a speed of 500 revolutions per minute at 70°C for 20 minutes, and take it out to obtain a liquid conductive epoxy resin;

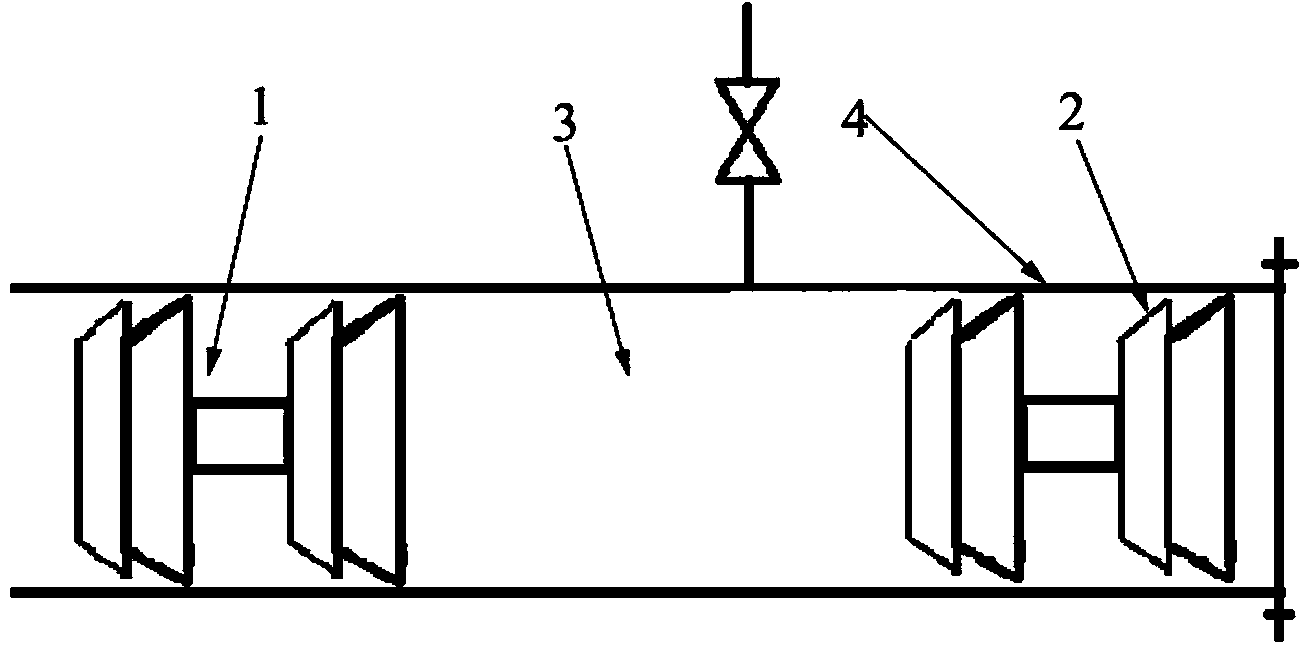

[0041] (4) Put two pigging balls into the pipeline to be repaired, such as figure 1 As shown, 1 and 2 are the front and rear pigs respectively. The liquid conductive epoxy resin 3 is injected...

Embodiment 2~5

[0047] (1) Prepare conductive epoxy resin base material according to the ratio in Table 1 below:

[0048]

Epoxy resin

Liquid polyurethane

Conductive powder

1

50%

15%

10%

25%

2

60%

15%

10%

15%

3

80%

10%

5%

5%

4

90%

3%

2%

5%

[0049] Prepare conductive epoxy resin additives according to the ratio in Table 2 below:

[0050]

Magnesium, aluminum, zinc alloy powder

Amine curing agent

1

30%

70%

2

35%

65%

3

40%

60%

4

45%

55%

5

55%

45%

[0051] 6

60%

40%

[0052] Mix any ratio in Table 1 with any ratio in Table 2, where the mass fraction of the base material in Table 1 is 45% to 75%, and the rest are additives in Table 2.

[0053] (2) Put the two pigging balls into the pipeline to be repaired, and inject the conductive epoxy resin between the two pigs through the valve and make full contact with the pipe wall;

[0054] (3) Maintain a pressure difference of 0.3 MPa between the front and rear of the two pigs, and push ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com