Aluminum oxide coating on metal substrate surface and preparation method thereof

A technology of alumina coating and metal substrate, which is applied in the anti-corrosion, anti-penetration and heat insulation coating of equipment and various steel pipes, the alumina coating on the surface of metal substrate and its preparation, and the field of superalloy, which can solve the problem Performance decline, matrix protection effect is not obvious, etc., to achieve the effect of lower crystal transformation temperature, excellent corrosion resistance, and improved wetting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

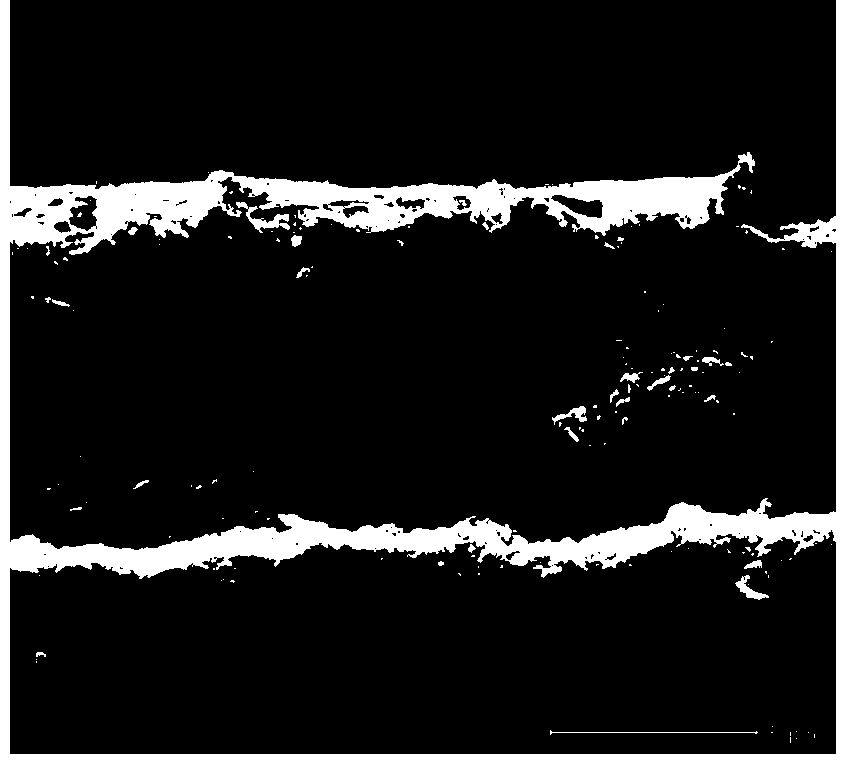

Examples

example 1

[0021] (1) Mix distilled water, aluminum isobutoxide and hydrochloric acid evenly in a molar ratio of 90:1:0.15, stir and react at 85°C for 4 hours, wherein hydrochloric acid is added during the stirring process, and finally a transparent sol is obtained;

[0022] (2) Put the above-prepared sol in a hydrothermal reactor with a filling degree of 70%, then seal the reactor, heat the internal sol to 210°C and keep it warm for 12 hours;

[0023] (3) Clean and degrease the surface of 40# carbon steel (chrome hardness = 35) and then polish it;

[0024] (4) Take out the sol after heat preservation treatment, and adopt the method of spin coating, that is, fixedly rotate the carbon steel on the spin coater, and continuously drip the above sol onto the surface of the substrate to cover the surface evenly, and the spin coater rotates at 50 rpm / minute;

[0025] (5) After 30 seconds of spin coating, stop the sol dripping and rotation, dry the substrate in the air until the surface liquid...

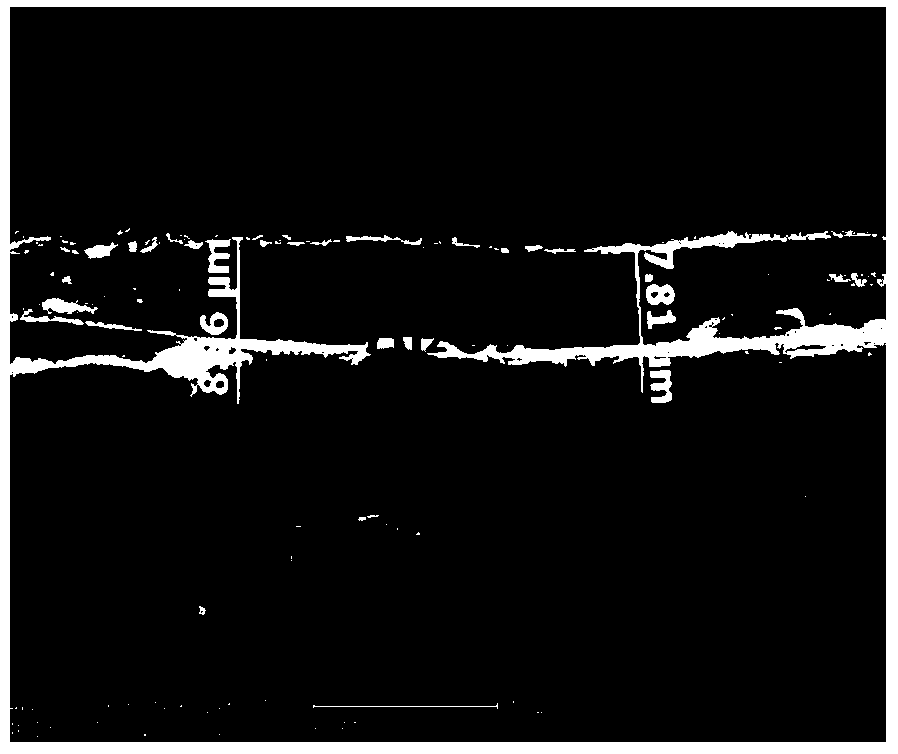

example 2

[0027] (1) Add deionized water and aluminum isopropoxide (analytically pure) into a three-necked flask at a molar ratio of 100 to 1, heat it to 85°C with magnetic stirring in a water bath, then add nitric acid with a molar ratio of 0.1, and continue to keep warm After stirring for 6 hours, a transparent alumina sol was obtained.

[0028] (2) The surface of the test martensitic steel (Chrome hardness = 30) is polished on a polishing machine with 600-mesh, 1500-mesh, and 3000-mesh sandpaper in sequence, and then the substrate is placed in acetone for ultrasonic cleaning to remove the surface After the oil stains were removed, they were placed in a vacuum drying oven for dry storage.

[0029] (3) The obtained alumina sol was introduced into a hydrothermal reaction kettle with a filling degree of 50%, and the reaction kettle was placed in an oven at 200° C. for 12 hours and then taken out.

[0030] (4) Fix the substrate on the spin coater with a rotating speed of 120 rpm. Use an ...

example 3

[0034] (1) Add pure water and aluminum isopropoxide (industrial grade) into a three-necked flask at a molar ratio of 100 to 1, mechanically stir in a water bath and heat to 80°C, then add nitric acid with a molar ratio of 0.1, and continue to keep warm and stir After 10 hours, a nearly transparent alumina sol was obtained.

[0035] (2) The surface of the 9Cr steel (Chrome hardness = 35) used in the test is polished and polished on a polishing machine with 600-mesh and 1500-mesh sandpaper in sequence, and then the substrate is placed in absolute ethanol for ultrasonic cleaning to remove the oil on the surface Store dry in a vacuum desiccator.

[0036] (3) The obtained alumina sol was introduced into a hydrothermal reaction kettle with a filling degree of 70%, and the reaction kettle was placed in an oven at 220° C. for 12 hours and then taken out.

[0037] (4) Fix the substrate on the spin coater with a rotating speed of 80 rpm. Use an acid burette to drop the above-mentioned ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com