Lithium sulfur battery

A lithium-sulfur battery and lithium salt technology, which is applied in the field of new lithium-sulfur battery systems, can solve the problems of reduced electrolyte conductivity, reduced battery performance, and loss of positive active materials, achieving improved cycle stability, improved battery efficiency, and reduced churn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

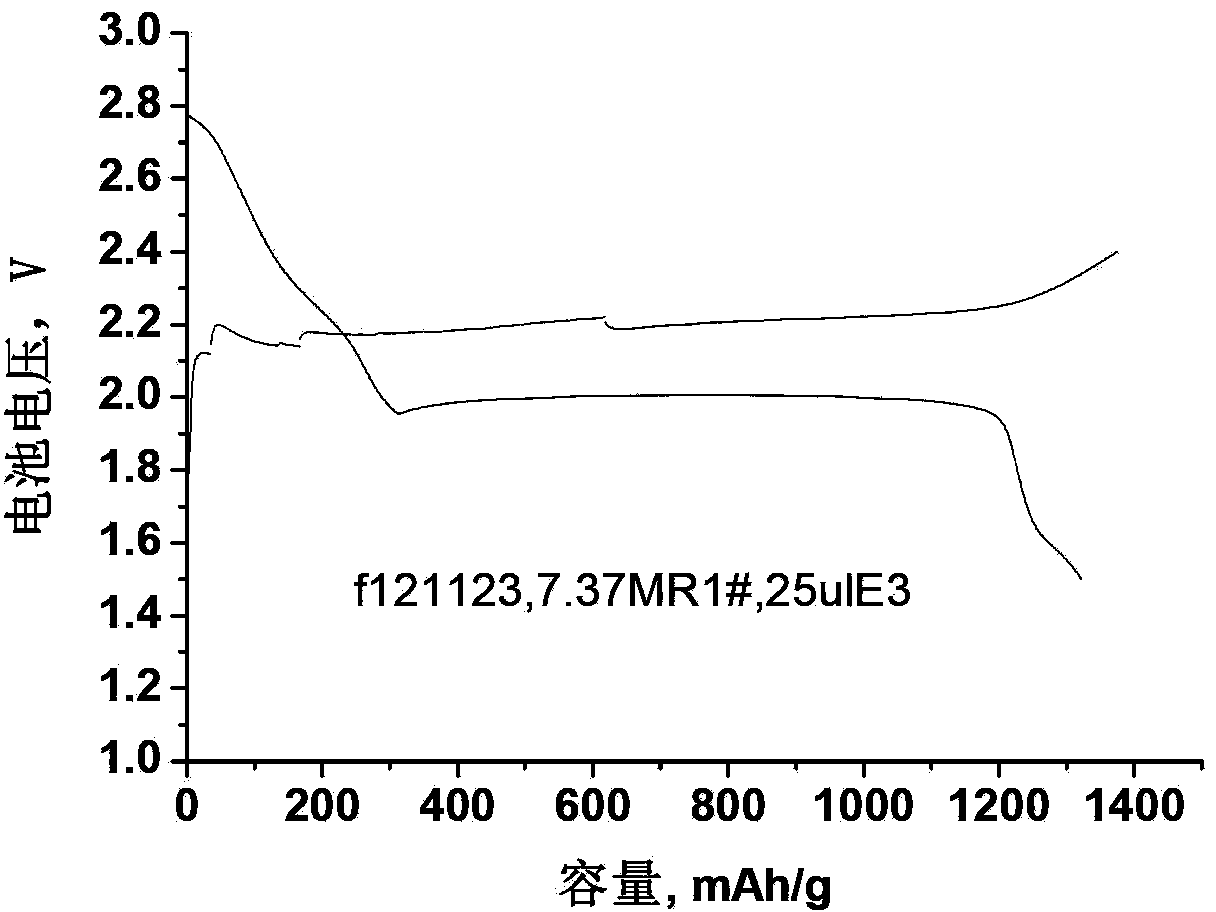

[0030] Prepare a lithium chloride / dimethyl sulfoxide electrolyte solution with a concentration of 1mol / L; place the Celgard2325 microporous membrane at room temperature in a Tris buffer solution of 10mmol / L dopamine / methanol / pH=9.5 (Tris buffer solution of methanol / pH=9.5 Buffer solution (volume ratio: 1:1) was immersed in the solution for 24 hours, washed with methanol, and dried overnight at 60°C under vacuum. Lithium sheet negative electrode is used, the above-prepared electrolyte, treated separator and carbon / sulfur compound are used as the positive electrode (polytetrafluoroethylene as the binder) to assemble a lithium-sulfur button battery, which is charged and discharged at a rate of 0.05C at about 30°C. The obtained voltage-capacity as figure 1 As shown, the discharge platform is 2.0V, the charging voltage is 2.2V, and the first discharge capacity is 1321mAh / g. It is demonstrated that LiCl / DMSO electrolyte can support the charge-discharge reaction of lithium-sulfur ba...

Embodiment 2

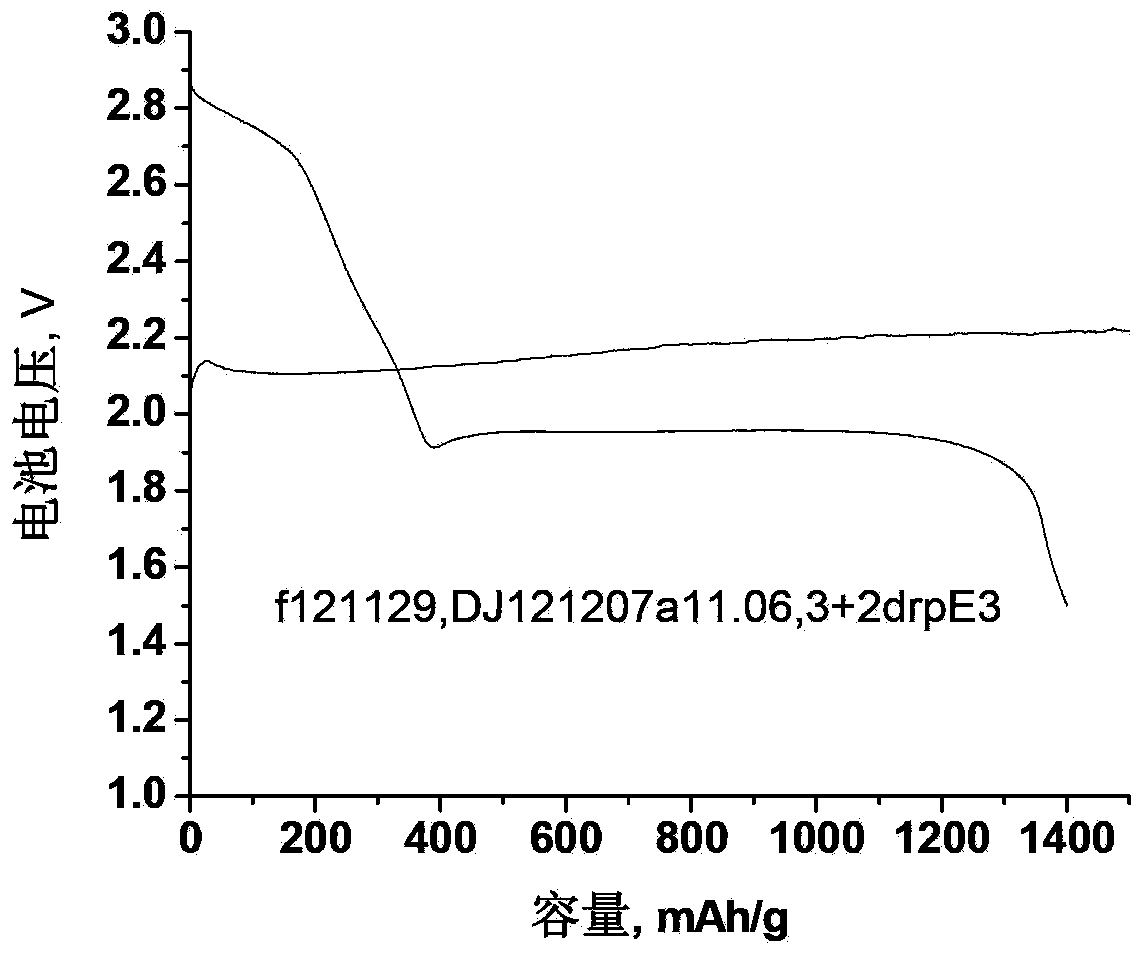

[0032]Celgard2325 was soaked in 10mmol / L dopamine / methanol / pH=9.5 Tris buffer solution (methanol / pH=9.5 Tris buffer volume ratio is 1:1) solution at room temperature for 24 hours, rinsed repeatedly with methanol, vacuumed at 60°C Dry overnight, and then hot press at 85°C and 3MPa for 2 minutes to reduce the pore size. Prepare a lithium chloride / dimethyl sulfoxide electrolyte with a concentration of 1 mol / L. The obtained microporous diaphragm and electrolyte were used to assemble a button battery, the negative pole was a lithium sheet, and the positive pole was a C / S composite electrode (polytetrafluoroethylene was used as a binder). The battery is charged and discharged at a rate of 0.05C at about 30°C, and the following figure 2 As shown in the voltage-capacity curve, the discharge platform is 1.96V, the charging voltage is 2.2V, and the first discharge capacity is as high as 1400mAh / g, which is better than that of Example 1, which proves that the combination of the micropo...

Embodiment 3

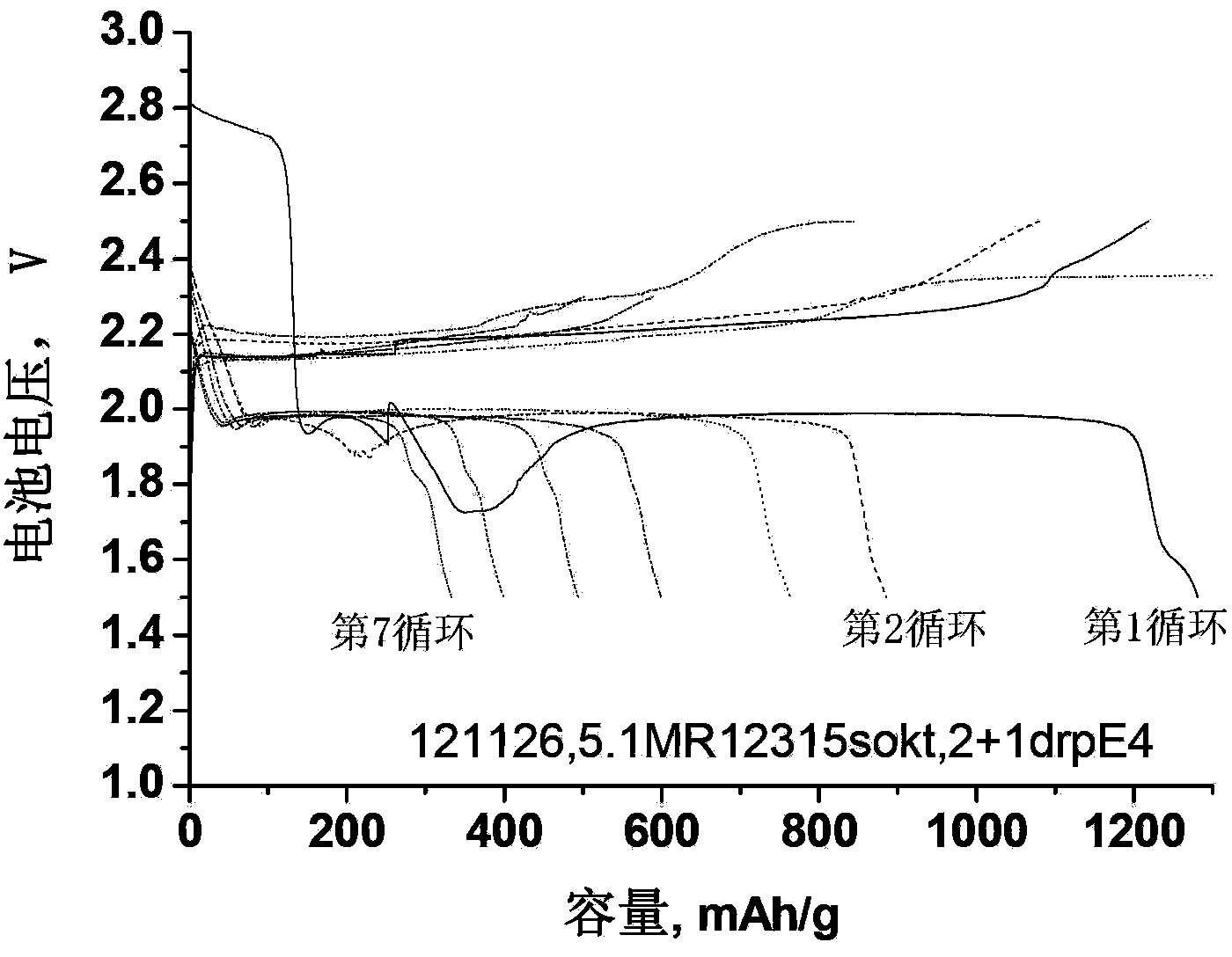

[0034] Celgard2325 was soaked in 10mmol / L dopamine / methanol / pH=9.5 Tris buffer solution (methanol / pH=9.5 Tris buffer volume ratio is 1:1) solution at room temperature for 24 hours, rinsed repeatedly with methanol, vacuumed at 60°C Dry overnight, and then hot press at 85°C and 3MPa for 2 minutes to reduce the pore size. Prepare a lithium bromide / dimethyl sulfoxide electrolyte with a concentration of 1 mol / L. The obtained microporous diaphragm and electrolyte were used to assemble a button battery, the negative pole was a lithium sheet, and the positive pole was a C / S composite electrode (polytetrafluoroethylene was used as a binder). The battery is charged and discharged at a rate of 0.05C at 30°C, and the obtained voltage-capacity curve is as follows image 3 As shown, the discharge platform is 1.98V, the charging voltage is 2.2V, the first discharge capacity reaches 1282mAh / g, and multiple charge and discharge cycles can be realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com