A kind of preparation method of rubber/clay composite material resistant to heat and oxygen aging

A composite material and nanocomposite material technology, which is applied in the field of preparing clay and rubber nanocomposite materials, can solve the problems that have not yet been reported in research, and achieve the effects of improving mechanical properties, better dispersibility, and simple and environmentally friendly preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

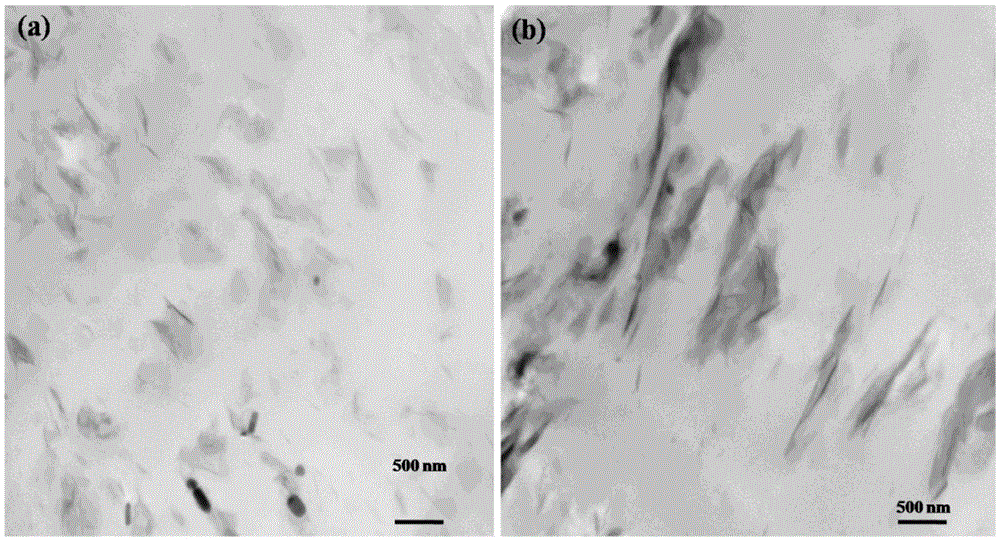

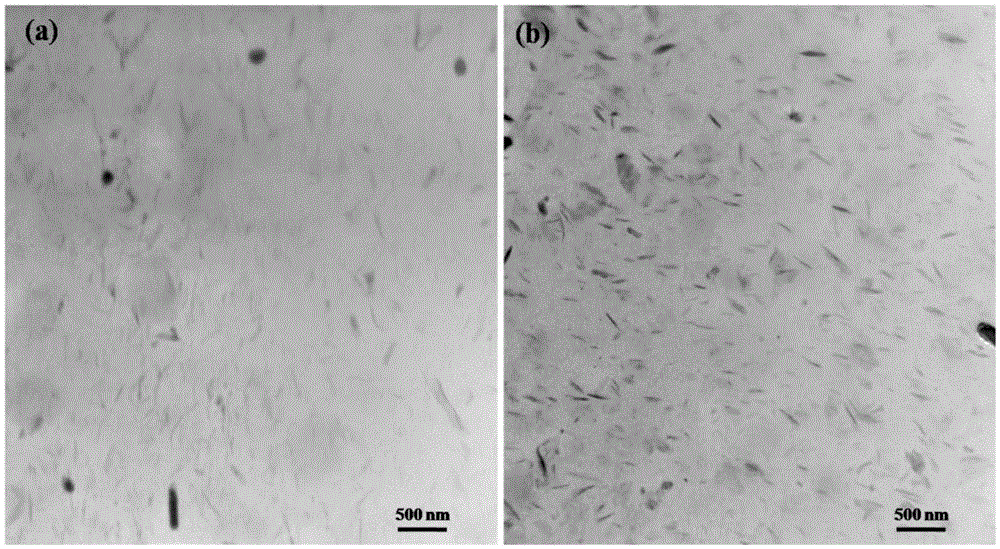

Embodiment 1

[0037] The sodium-based montmorillonite and deionized water were prepared as a 5% mass fraction suspension in proportion, stirred at a speed of 1600 rpm for 8 hours, and then allowed to stand for 24 hours to obtain a stable upper layer with a solid content of 2% Aqueous clay suspension. Measure 250 grams of the above-mentioned clay suspension and conduct ultrasonic peeling treatment (ultrasonic power is 750 watts, ultrasonic time is 3 seconds, interval time is 2 seconds, working cycle is 99 times, the whole process is repeated 6 times); 0.375 g of dopamine, 0.3 g Tris, adjust the pH to 8.5, react for 4 hours at room temperature and high-speed stirring (1000 rpm) to obtain a suspension of dopamine modified clay; combine the suspension of dopamine modified clay with 510.2 grams of styrene butadiene latex (brand 1502, solid content 19.6%) stir and mix at room temperature for 30 minutes at a stirring speed of 600 rpm; then add the dopamine-modified clay-latex mixture to 3 liters (m...

Embodiment 2

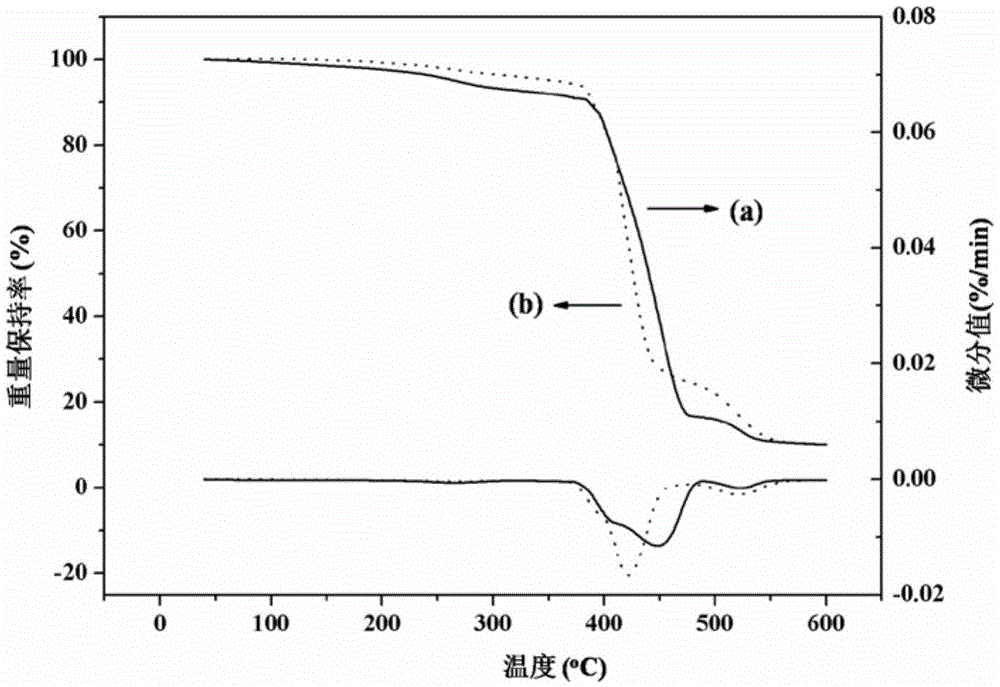

[0039] The operation steps are the same as in Example 1. Measure 500 grams of sodium-based montmorillonite suspension with a mass fraction of 2%, after ultrasonic treatment (ultrasonic power is 750 watts, ultrasonic time is 3 seconds, interval time is 2 seconds, working cycle 99 times, the whole process is repeated 6 times ), add 1.0 g of dopamine, 0.75 g of tris, adjust the pH to 9, and react for 6 hours to obtain a suspension of dopamine modified clay; combine it with 510.2 g of styrene butadiene latex (brand 1502, solid content 19.6%, below Same) uniform mixing; flocculation, washing, drying, mixing and vulcanization to obtain dopamine modified clay / styrene butadiene rubber nanocomposite, including 100 parts of styrene butadiene rubber and 10 parts of dopamine modified clay. Other process conditions are the same as in Example 1. The mechanical properties of composite materials are shown in Table 1, and the thermogravimetric analysis curve of composite materials is shown in ...

Embodiment 3

[0041] The sodium-based rectorite and deionized water were configured as a 5% mass fraction suspension in proportion, stirred at a speed of 1600 rpm for 8 hours, and then allowed to stand for 24 hours to obtain a stable upper layer with a solid content of 2% Aqueous clay suspension. Measure 200 grams of clay suspension with a mass fraction of 2%, and after ultrasonic treatment (ultrasonic power is 1000 watts, ultrasonic time is 3 seconds, interval time is 2 seconds, working cycle is 99 times, the whole process is repeated 8 times), add 0.3 Cedopa, 0.24 g of tris, adjusted to pH 8.5, reacted for 4 hours to obtain a suspension of dopa modified clay; combine it with 166.7 g of natural rubber latex (solid content 60%, the same below) and 33 ml Ionized water is mixed uniformly; after flocculation, washing, and drying, a dopa modified clay / natural rubber nanocomposite is obtained, including 100 parts of natural rubber and 4 parts of dopa modified clay; on a two-roll mill, the dopa mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com