Integrative method and device for treating wastewater with advanced oxidation

A technology for advanced oxidation and wastewater treatment, applied in biological treatment devices, chemical instruments and methods, special compound water treatment, etc., can solve the problems of low catalytic oxidation efficiency, large aeration volume, gas adsorption, etc., to improve utilization rate and Effects of energy utilization, improvement of processing efficiency, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In this embodiment, the integrated method for advanced oxidation treatment of wastewater according to the present invention is used to pretreat high-concentration refractory wastewater.

[0054] The raw water quality of wastewater from a coking plant is shown in Table 1.

[0055] Table 1 Raw water quality of wastewater from a coking plant

[0056]

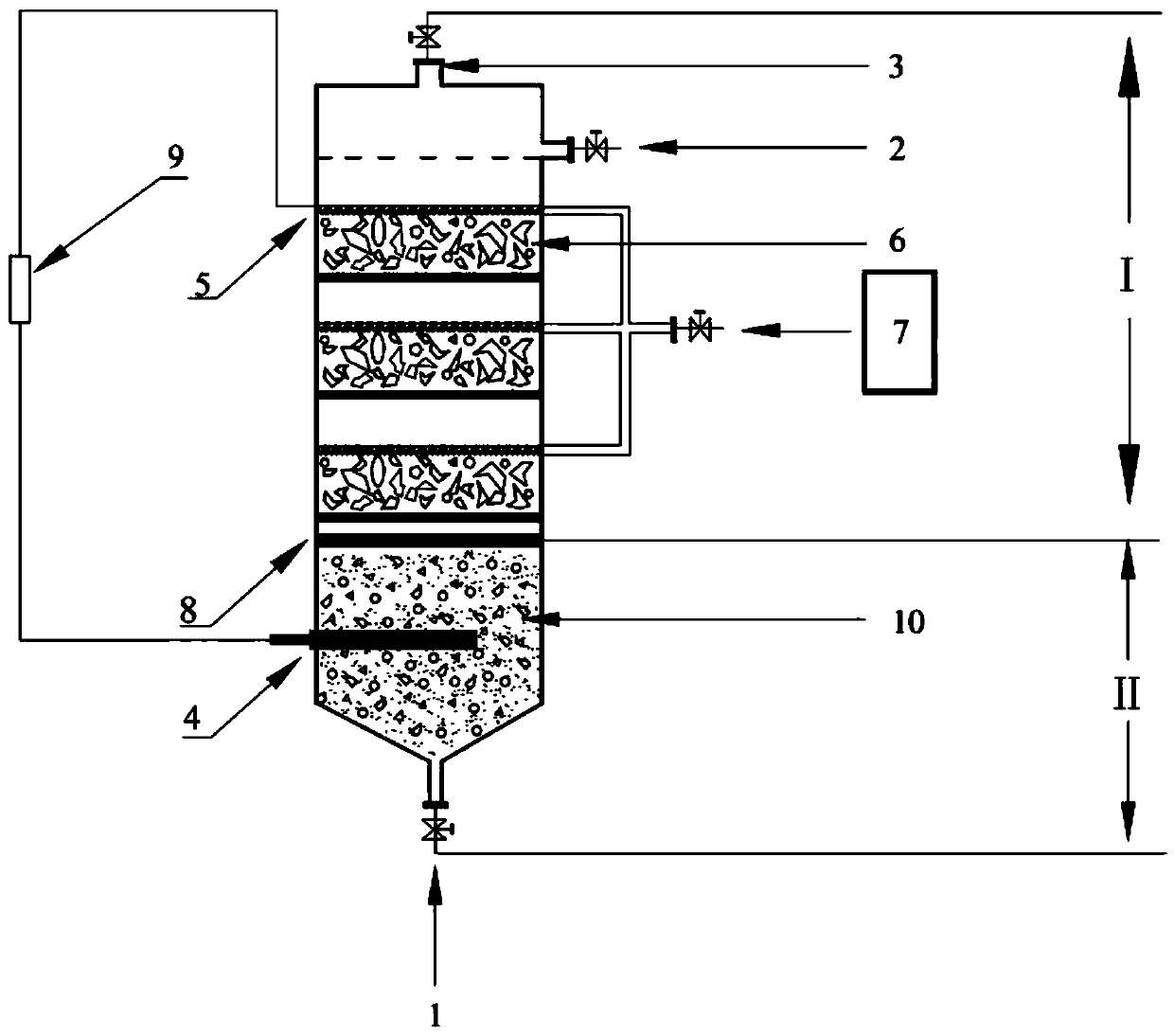

[0057] The raw water of coking wastewater has a pH of 8. Oxygen and wastewater are fed into the reactor respectively. The gas-water flow rate ratio is 30:1. The oxygen supply method is multi-stage cathode plate microporous aeration.

[0058] The height-to-diameter ratio of the reactor is 6:1, the mud-to-water volume ratio is 1:1, and the anode anaerobic microbial reaction chamber II adopts an internal circulation waterway design with a circulation ratio of 3:1.

[0059] After reacting for 4 hours, samples were taken to measure COD, volatile phenol and chromaticity. The water quality after treatment is shown in Table 2. ...

Embodiment 2

[0063] In this embodiment, the integrated method for advanced oxidation treatment of wastewater according to the present invention is used for advanced treatment of low-concentration refractory wastewater.

[0064] Table 3 shows the effluent quality of the secondary sedimentation tank after biochemical treatment in a coking plant.

[0065] Table 3 The effluent water quality of the secondary settling tank after biochemical treatment in a coking plant

[0066]

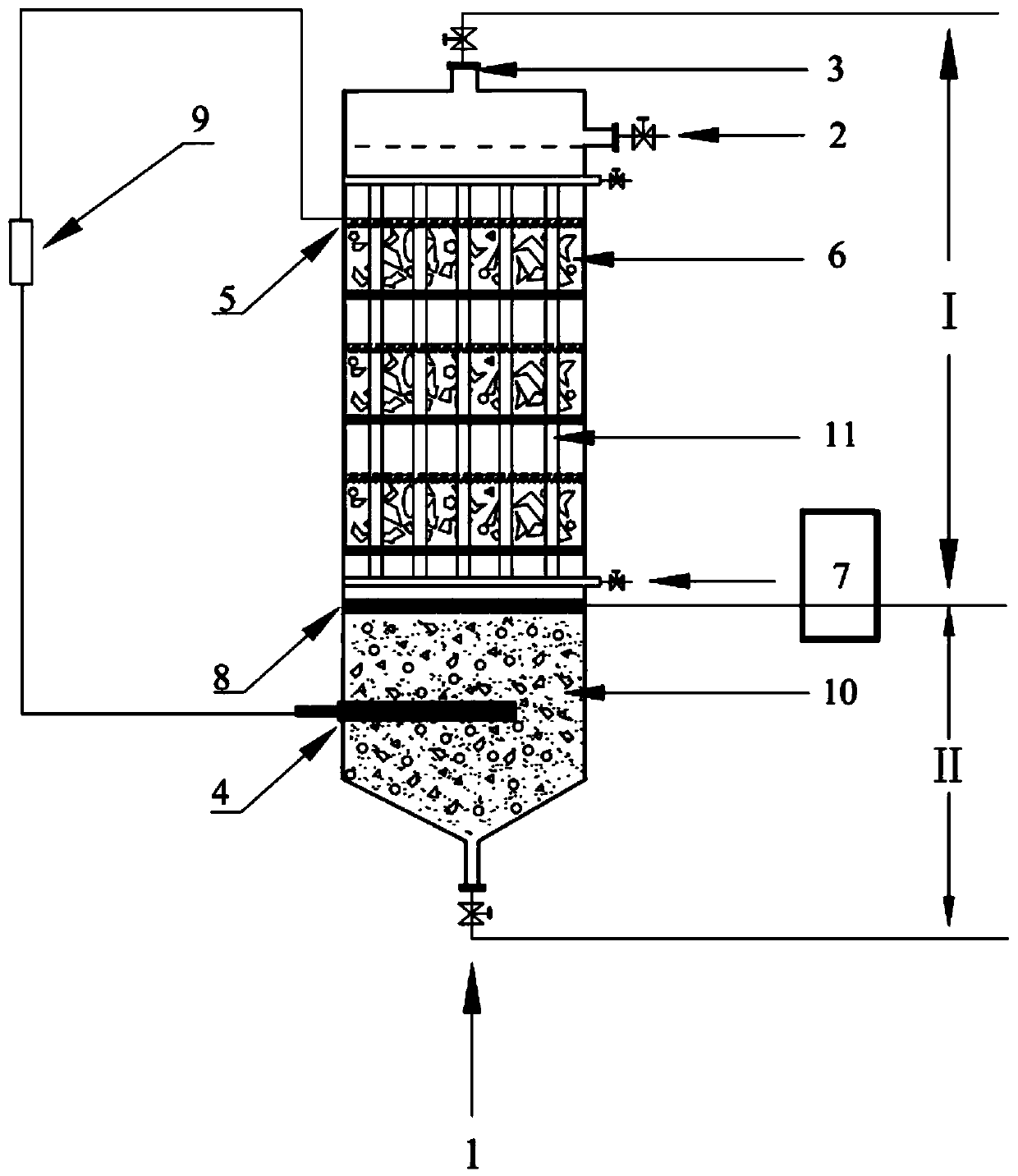

[0067] The pH of the raw water effluent from the coking wastewater secondary sedimentation tank is 6.5. Oxygen and wastewater are fed into the reactor respectively. The gas-water flow rate ratio is 15:1. The oxygen supply method adopts the hollow fiber membrane module 11 to supply gas.

[0068] The aspect ratio of the reactor is 6:1. The volume ratio of mud to water is 1:1, and the anode anaerobic microbial reaction chamber II adopts the design of internal circulation waterway, and the circulation ratio is 1:2.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com