Composite film for achieving efficient photoinduction electron transfer in visible region, preparation method and application

An electron transfer and composite technology, which is applied in the direction of photosensitive equipment, capacitor parts, etc., can solve the problem that the composite film cannot realize electron transfer, and achieve the effect of transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method of the nitrogen-doped carbon nano-dots preferably includes:

[0035] Step 1: Mix and dissolve citric acid and urea in deionized water to obtain a transparent solution;

[0036] Step 2: microwave the mixed solution obtained in step 1 to obtain brown-black viscous liquid;

[0037] Step 3: drying, dissolving, and centrifuging the brown-black viscous liquid obtained in Step 2 to obtain nitrogen-doped carbon nano-dots.

[0038]The mass ratio of citric acid and urea in the present invention is preferably 1:2, the microwave heating power of step 2 is preferably 500-900W, and the heating time is preferably 5-10 minutes; The liquid is dried, then dissolved in deionized water, and centrifuged to remove large insoluble aggregates of carbon nano-dots to obtain nitrogen-doped carbon nano-dots. The centrifugal speed is preferably 8000 rpm.

[0039] The present invention also provides a method for preparing a composite film capable of realizing high-efficienc...

Embodiment 1

[0049] ① Mix and dissolve citric acid and urea in deionized water at a mass ratio of 1:2 to obtain a transparent solution;

[0050] ②The mixed solution obtained in ① was reacted by microwave heating for 5 minutes, the heating power was 700w, and a brown-black viscous liquid was obtained;

[0051] ③Dry the brown-black viscous liquid obtained in ②, dissolve it in deionized water, and centrifuge three times at a speed of 8000 rpm to remove larger insoluble aggregates of carbon nano-dots to obtain nitrogen-doped carbon nano-dots.

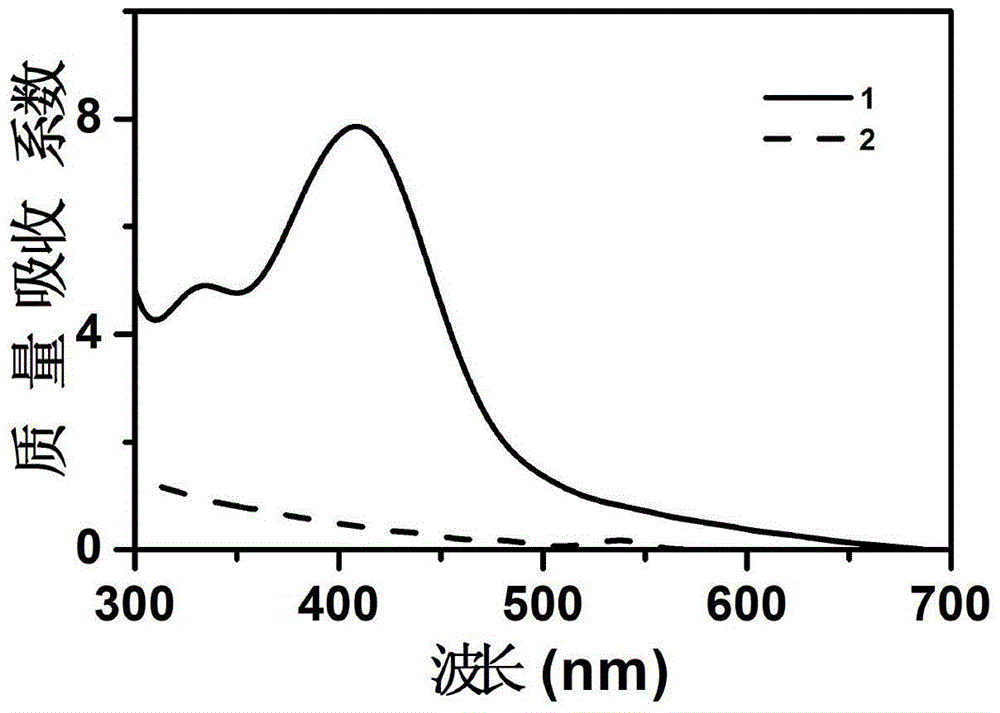

[0052] figure 1 It is the mass absorption coefficient spectrogram of nitrogen-doped carbon nano-dot (label 1 curve) and commercialized CdSeZnS quantum dot (label 2 curve) used in the present invention, from figure 1 It can be seen that the absorption ability of the nitrogen-doped carbon nano-dot material of the present invention to visible light is much higher than that of traditional semiconductor quantum dots.

Embodiment 2

[0054] ① Spin-coat a transparent ITO conductive film on a glass substrate;

[0055] ②Using the transparent ITO conductive film as the electron extraction layer, the titanium dioxide slurry was spin-coated on the glass substrate containing the ITO film at a spin-coating speed of 2000 rpm (the spin-coating time was 70s) to obtain a titanium dioxide film, and the titanium dioxide film was placed Calcining in a muffle furnace at a temperature of 500°C for 45 minutes to obtain a titanium dioxide film with a nano-mesoporous structure;

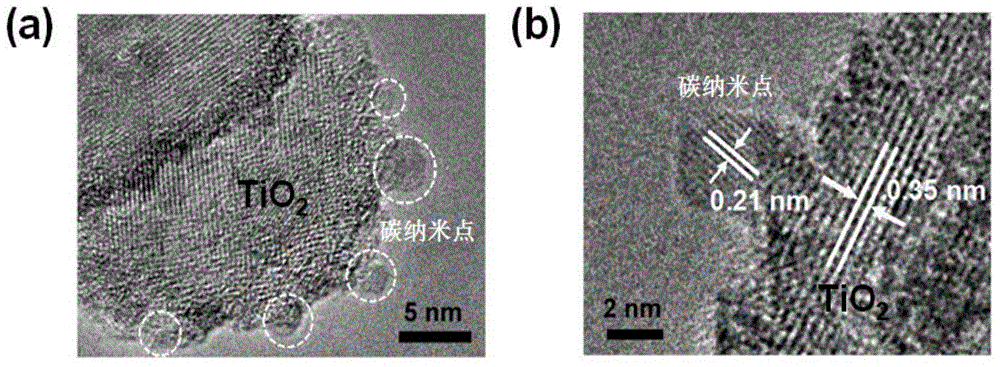

[0056] ③ Soak the titanium dioxide film with nano-mesoporous structure obtained in ② in the aqueous solution of carbon nano-dots for 6 hours, absorb carbon nano-dots as the photosensitive layer, the concentration of carbon nano-dots is 5 mg per milliliter, and then rinse the film repeatedly with deionized water. The thin film is used to remove the carbon nano-dots that are not adsorbed on the titanium dioxide, and after natural drying, a composite th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com