A kind of amoxicillin dispersible tablet, its preparation method and application

A technology of amoxicillin and amoxicillin original drug, applied in the field of amoxicillin dispersible tablets, and its preparation field, can solve the problems of large differences in splinter, tablet weight, poor powder fluidity, etc., and achieve fast absorption, fast onset, and stability Sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

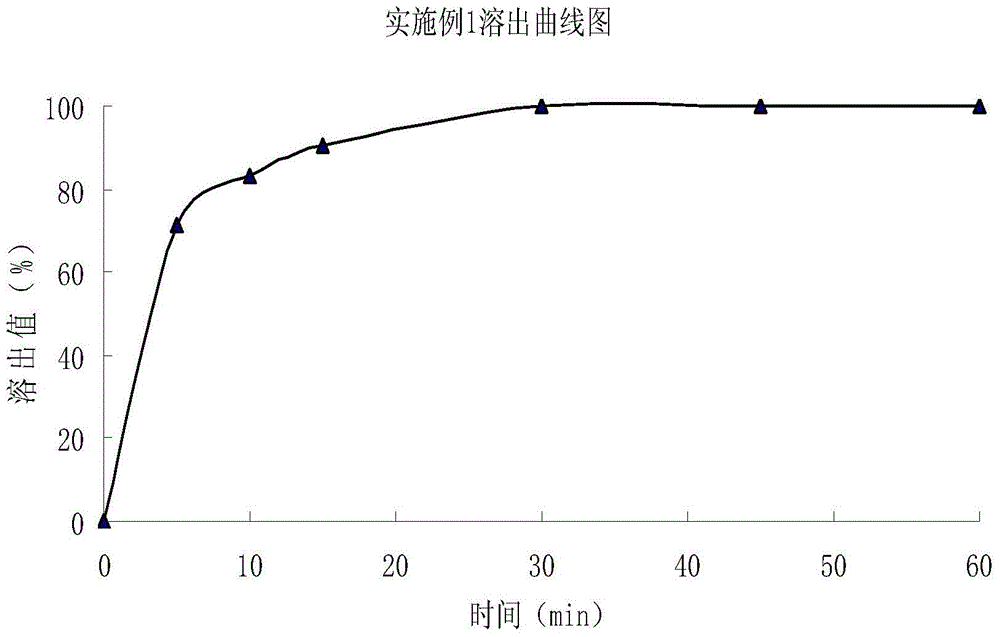

Embodiment 1

[0050] prescription:

[0051]

[0052] Preparation:

[0053] (1) Pulverize the amoxicillin raw material and pass through an 80-mesh sieve;

[0054] ⑵According to the above prescription, anhydrous lactose and crospovidone were mixed in a CH200 mixer for 30 minutes, and passed through a 80-mesh sieve;

[0055] (3) Put the materials obtained in the above two steps into a V-shaped mixer, add the prescribed amount of micropowder silica gel and magnesium stearate, and mix for 30 minutes to fully mix the materials;

[0056] (4) The mixed material obtained from (3) is directly compressed into tablets to obtain dispersible tablets of amoxicillin, with a specification of 0.25 g per tablet.

Embodiment 2

[0058] prescription:

[0059]

[0060] Preparation:

[0061] (1) Pulverize the amoxicillin raw material and pass through an 80-mesh sieve;

[0062] (2) According to the above prescription, microcrystalline cellulose, sodium carboxymethyl starch and aspartame were mixed in a CH200 mixer for 30 minutes, and passed through a 80-mesh sieve;

[0063] (3) Put the materials obtained in the above two steps into a V-shaped mixer, add the prescribed amount of micropowder silica gel and magnesium stearate, and mix for 30 minutes to fully mix the materials;

[0064] (4) The mixed material obtained from (3) is directly compressed into tablets to obtain dispersible tablets of amoxicillin, with a specification of 0.25 g per tablet.

Embodiment 3

[0066] prescription:

[0067]

[0068] Preparation:

[0069] (1) Pulverize the amoxicillin raw material and pass through an 80-mesh sieve;

[0070] (2) According to the above prescription, microcrystalline cellulose, crospovidone and aspartame were mixed in a CH200 mixer for 30 minutes, and passed through a 80-mesh sieve;

[0071] (3) Put the materials obtained in the above two steps into a V-shaped mixer, add the prescribed amount of micropowder silica gel and magnesium stearate, and mix for 30 minutes to fully mix the materials;

[0072] (4) The mixed material obtained from (3) is directly compressed into tablets to obtain dispersible tablets of amoxicillin, with a specification of 0.25 g per tablet.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com