A falling pyrolyzer

A pyrolyzer and pyrolysis technology, used in special forms of dry distillation, biofuels, coke ovens, etc., can solve the problems of inability to efficiently complete pyrolysis, unfavorable full pyrolysis of large particles, and short residence time. The ability to expand and contract is strong, it is not easy to raise dust, and the effect of improving the calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

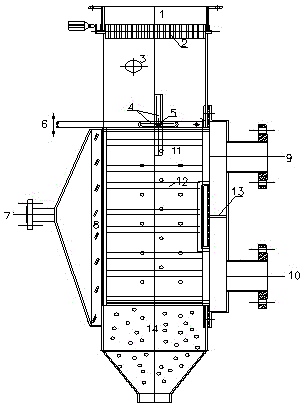

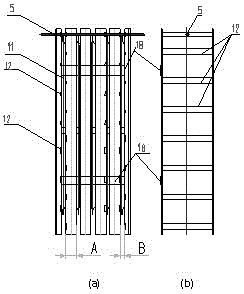

[0049] figure 1 It shows a specific optimized implementation of a descending pyrolyzer provided by the present invention. The pyrolyzer of this specific embodiment comprises a feeding port 1, a uniform feeding mechanism 2, and a water vapor outlet 3 in the preheating section; It is composed of a car frame connected by connecting pieces 18; the main reactor is composed of a vertical plate heat transfer surface 11; one side has a volatile matter filter layer 8 and its outlet 7; the other side has a heat source, that is, a heat source inlet for high-temperature flue gas 9 and heat source outlet 10; there is a heat source partition 13 between the inlet and outlet of the heat source; biomass and waste are discharged into the charcoal discharge section 14 after the main reactor is reacted; they are continuously discharged after a proper stay in the discharge section 14. The distance between the heat transfer surfaces 11 of the vertical plate (material side) is A, and the size is 1....

Embodiment 2

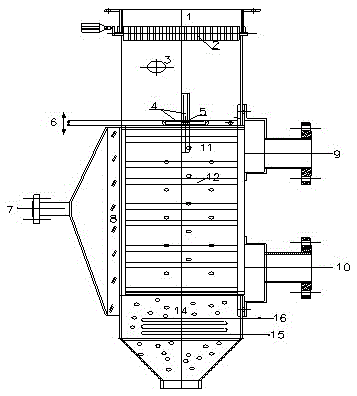

[0056] figure 2 It shows another specifically optimized implementation of the descending pyrolyzer provided by the present invention. The pyrolyzer of this specific embodiment comprises a feeding port 1, a uniform feeding mechanism 2, and a water vapor outlet 3 in the preheating section; It is composed of a car frame connected by connecting pieces 18; the main reactor is composed of a membrane-type vertical tube heat transfer surface 11; one side has a volatile matter filter layer 8 and its outlet 7; the other side has a heat source, that is, the inlet of high-temperature flue gas 9 and outlet 10; biomass and waste are discharged into the charcoal discharge section 14 after the main reactor reacts; they are continuously discharged after proper cooling in the charcoal discharge section 14. The distance between the heat transfer surfaces 11 of the film vertical tube is A; the diameter of the heat transfer surface is d; the length of the heat transfer surface is C; the width of...

Embodiment 3

[0060] After a certain sludge is dried, the moisture content is 30%, and the largest particle is below 28mm. Using the existing rotary pyrolysis reactor is easy to generate dust. A cyclone dust collector needs to be installed, and the cyclone dust collector is often blocked by tar. Adopt falling type pyrolyzer of the present invention ( figure 2 ), the sludge is fed to the preheating section by the uniform feeding mechanism 2; the generated water vapor is discharged from the water vapor outlet 3 of the preheating section, so that the moisture in the volatile matter is reduced and the calorific value is increased. The dry pre-reacted material then descends to the main reactor, which consists of vertical plates ( Figure 4) heat transfer surface 11, the distance B on the heat source side of the vertical plate is 15mm, high-temperature flue gas flows through, and the distance A on the sludge side is 45mm, heated to 600°C by the high-temperature flue gas, and the volatile matter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com