Water floating type pesticide controlled-release granule carrier and applications thereof

A water surface floating and controlled release technology, which is applied in the fields of agricultural gas emission reduction, chemicals for biological control, application, etc., can solve the problems of fast release of active ingredients, weak adsorption, and influence on drug efficacy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 500g of dry corn stalks, crush them and put them into several crucibles in batches, cover the crucibles, put them into a muffle furnace, heat up to 350°C, keep them warm for 3 hours, and cool down the crucibles to room temperature, then take them out of the crucibles Residual solid carbonaceous material. Add hydrochloric acid with a concentration of 2mol / L at a ratio of 20mL / g carbonaceous material, soak continuously for 24h and then filter with suction, dry the filtered solid matter, crush and sieve (<0.10mm), and obtain 105g of acidified biocarbonaceous material .

[0036]Take 50g of acidified biological carbonaceous material, mix them with 10g of sodium bicarbonate and 2g of sodium lignosulfonate respectively, spray the binder aqueous solution containing 2g of sodium alginate to obtain wet powder, and use a swing granulator to produce Particles with an average particle diameter of about 0.30 mm are dried to obtain a granular carrier.

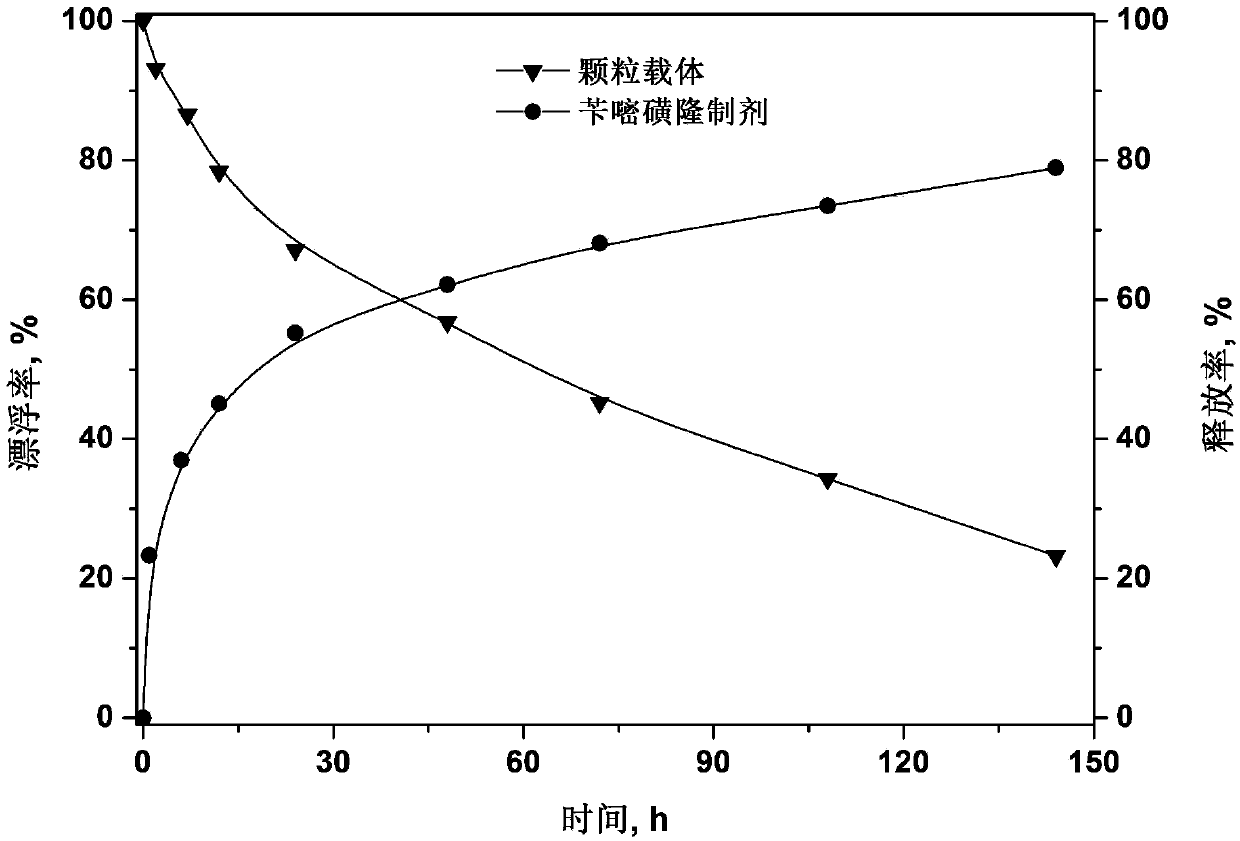

[0037] Take 1g (m0) of ...

Embodiment 2

[0041] Get 50g of the acidified biological carbonaceous material material described in Example 1, after mixing evenly with 10g sodium bicarbonate and 2g sodium lignosulfonate respectively, mix in 15g of bensulfuron-methyl original drug, spray with 2g of sodium alginate Binder aqueous solution to obtain wet powder, using a swing granulator to obtain bensulfuron-methyl granules with an average particle size of about 0.30 mm, and drying to obtain bensulfuron-methyl granule preparations. The content of bensulfuron-methyl in the granular preparation was determined to be 18.0% by sampling.

[0042] Get bensulfuron-methyl granule 40mg (benzsulfuron-methyl content is 7.2mg (M 0 )) into a stoppered Erlenmeyer flask filled with 300mL of distilled water. Place the Erlenmeyer flask in a 25°C water bath and shake at constant temperature. After a certain time interval, water samples were taken to analyze the concentration of bensulfuron-methyl, and the mass M of bensulfuron-methyl release...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com