Ciprofloxacin hydrochloride oral solid preparation and preparation process thereof

A technology of ciprofloxacin hydrochloride and solid preparation, applied in the directions of pharmaceutical formulation and drug delivery, can solve the problems of inconsistent drug efficacy, influence drug efficacy, large difference in pH of gastrointestinal tract, etc., so as to ensure drug safety and improve biological efficiency. The effect of the degree of utilization and the simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

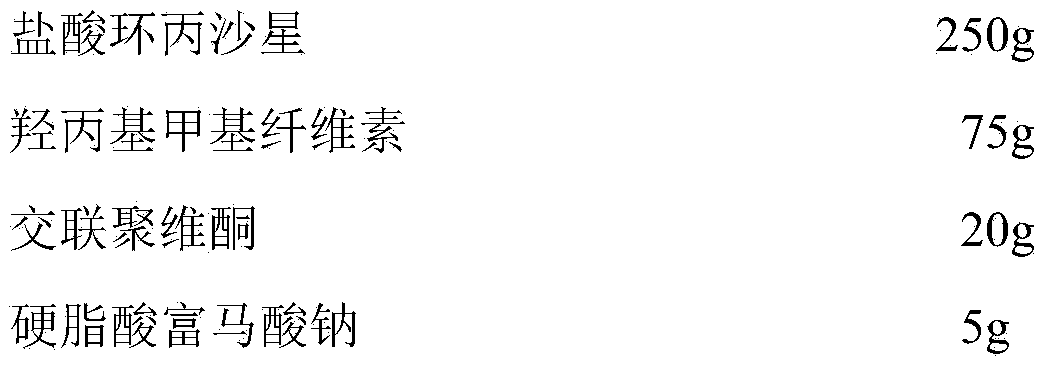

Embodiment 1

[0018]

[0019] Preparation Process:

[0020] (1) Prescription quantity Weigh ciprofloxacin hydrochloride and hydroxypropyl methylcellulose, add to 2000ml water, 100r / min electric stirring, stirring for 2h, obtain a clear and transparent solution, spray this solution into the spray through a peristaltic pump In the dryer, the spray temperature is set to 70°C, and the spray-dried fine powder is collected to obtain a dispersion;

[0021] (2) Take the above-mentioned dispersion in proportion, and put the multi-sport mixer with the crospovidone and sodium stearate fumarate of the prescribed amount, mix for 10min, measure the semi-finished product content, then carry out on the automatic capsule filling machine Filling at a filling speed of 800 capsules / min to obtain ciprofloxacin hydrochloride capsules, which are inner-wrapped on an aluminum-plastic packaging machine, and the heating temperature of the inner-wrapped blister board is 110° C., and finally the outer packaging is r...

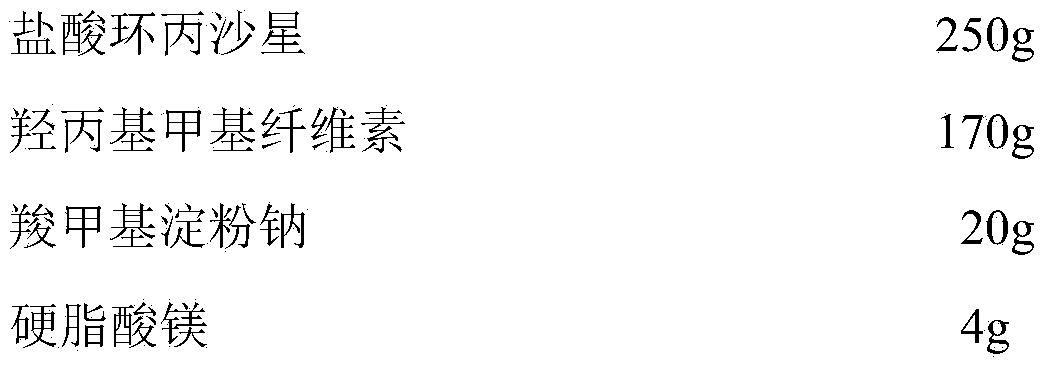

Embodiment 2

[0023]

[0024] Preparation Process:

[0025] (1) Prescription quantity Weigh ciprofloxacin hydrochloride and hydroxypropyl methylcellulose, add to 2500ml water, 150r / min electric stirring, stirring for 1.5h, obtain clear and transparent solution, spray this solution into the In the spray dryer, the spray temperature is set to 75°C, and the spray-dried fine powder is collected to obtain a dispersion;

[0026] (2) Take the above-mentioned dispersion in proportion, put the multi-sport mixer with the sodium carboxymethyl starch and magnesium stearate of the prescribed amount, mix for 15min, measure the semi-finished product content, then fill on the automatic capsule filling machine, fill The speed is 700 capsules / min to obtain ciprofloxacin hydrochloride capsules, which are inner-wrapped on an aluminum-plastic packaging machine, and the heating temperature of the inner-wrapped blister board is 105° C., and finally the outer packaging is ready.

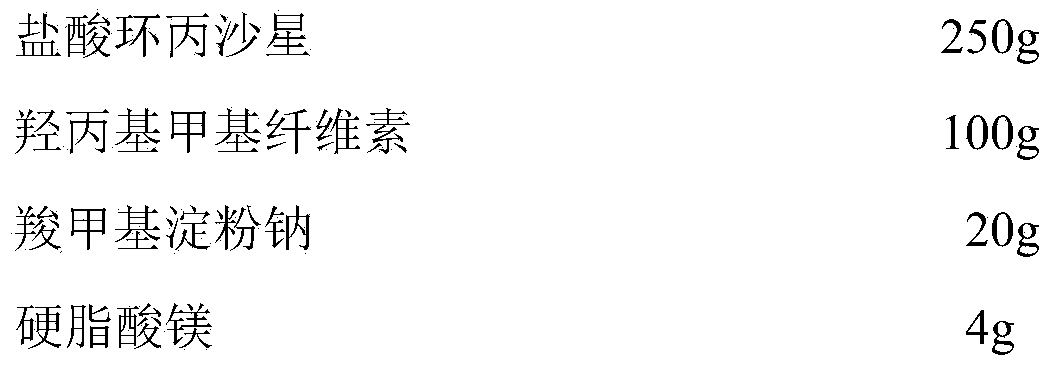

Embodiment 3

[0028]

[0029] Preparation Process:

[0030] (1) Prescription quantity Weigh ciprofloxacin hydrochloride and hydroxypropyl methylcellulose, add them to 2200ml of water, 200r / min electric stirring, stirring for 1h, obtain a clear and transparent solution, and spray this solution into the spray through a peristaltic pump In the dryer, the spray temperature is set to 65°C, and the spray-dried fine powder is collected to obtain a dispersion;

[0031] (2) Take the above-mentioned dispersion in proportion, put in a multi-motion mixer with the sodium carboxymethyl starch and magnesium stearate of the prescribed amount, mix for 20min, measure the semi-finished product content, then fill on the automatic capsule filling machine, fill The speed is 650 capsules / min to obtain ciprofloxacin hydrochloride capsules, which are inner-wrapped on an aluminum-plastic packaging machine, and the heating temperature of the inner-wrapped blister board is 105° C., and finally the outer packaging i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com