Platinum/carbon-based nano composite material, and preparation method and application thereof

A technology of carbon-based nanometers and carbon-based materials, which is applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems that cannot meet the needs of large-scale application of fuel cells and limit the scale of supported platinum catalysts Production and other issues, to achieve the effect of good industrial prospects, easy access, and strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

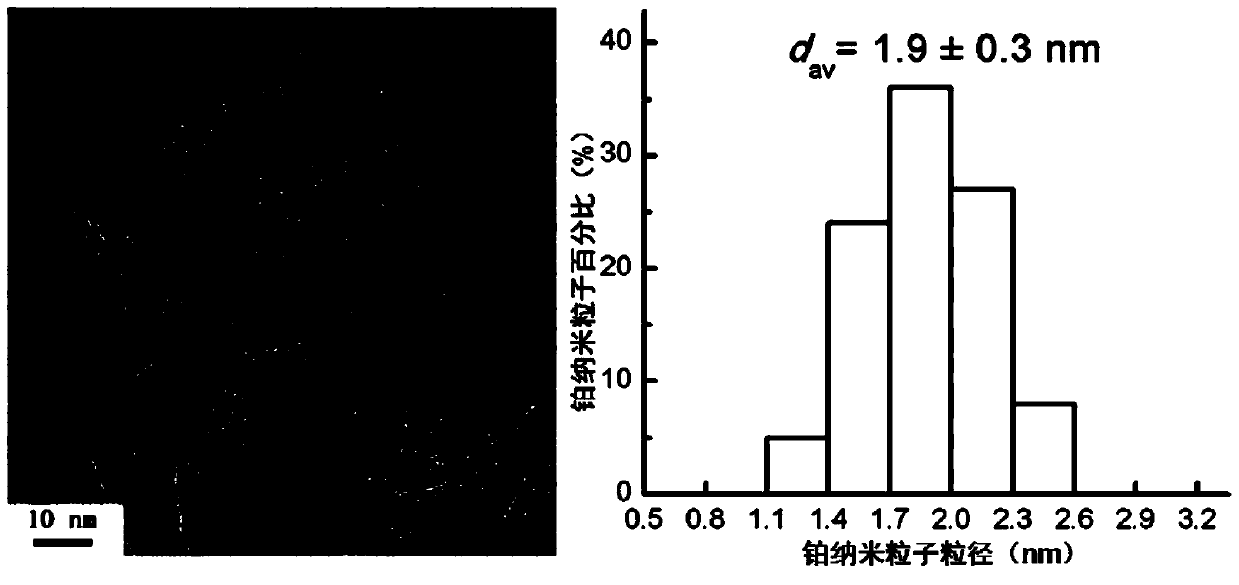

[0049] Example 1, Pt / CNH nanocomposite material (PCNb-20) and its electrocatalytic performance test

[0050] 1) Ultrasonic disperse CNH in ethylene glycol, dissolve sodium hydroxide in ultrapure water, and mix the two evenly. Add 1.96g / L ethylene glycol solution of chloroplatinic acid hexahydrate under stirring, mix well, and then ultrasonically disperse for 30 minutes to obtain CNH concentration of 0.5g / L, chloroplatinic acid hexahydrate concentration of 0.392g / L, volume of alcohol and water A suspension with a ratio of 9:1 has a pH ~12.

[0051] 2) Transfer the mixed liquid to the irradiation tube, pass argon gas for 15 minutes to remove the oxygen in the system, and seal the tube mouth 60 Coγ-rays were irradiated at room temperature with a dose rate of about 25Gy min -1 , The absorbed dose is 25kGy.

[0052] 3) After the irradiation, the sample is filtered through a polypropylene (PP) membrane with a pore size of 0.45 μm. The filtered filter cake is rinsed with ultrapur...

Embodiment 2

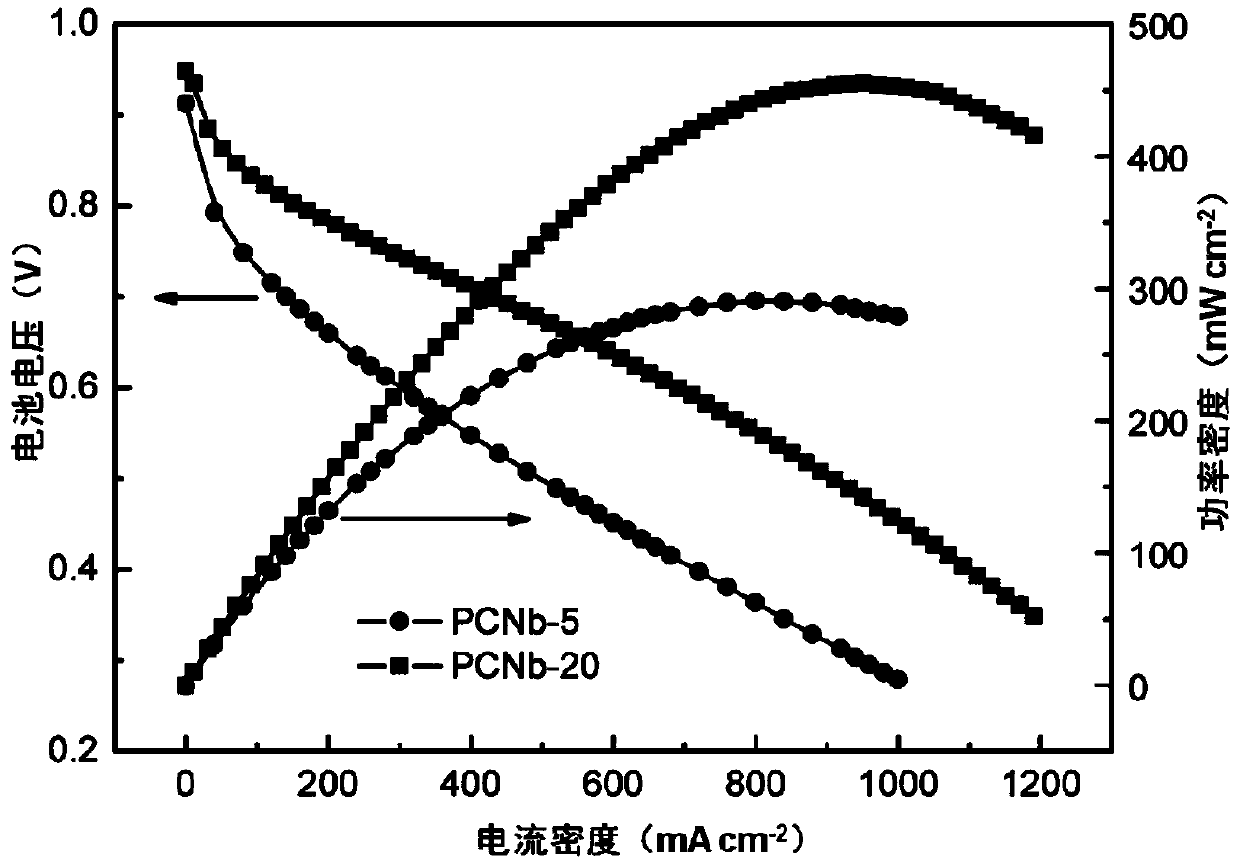

[0055] Example 2, Pt / CNH nanocomposite material (PCNb-5) and its electrocatalytic performance test

[0056] Consistent with the preparation method in Example 1, step 1) was changed to: ultrasonically disperse CNH in ethylene glycol, dissolve sodium hydroxide in ultrapure water, and mix the two evenly. Add 1.96g / L ethylene glycol solution of chloroplatinic acid hexahydrate under stirring, mix well, and then ultrasonically disperse for 30 minutes to obtain CNH concentration of 0.5g / L, chloroplatinic acid hexahydrate concentration of 0.098g / L, volume of alcohol and water A suspension with a ratio of 9:1 has a pH ~12.

[0057] After obtaining the Pt / CNH nanocomposite material in the form of black fluffy powder, the platinum loading in the composite material was measured by ICP-AES and TGA to be 5 wt%, and the sample was named PCNb-5.

[0058] Consistent with the electrocatalytic performance test method in Example 1, the performance of the PEMFC single cell using the PCNb-5 nanoco...

Embodiment 3

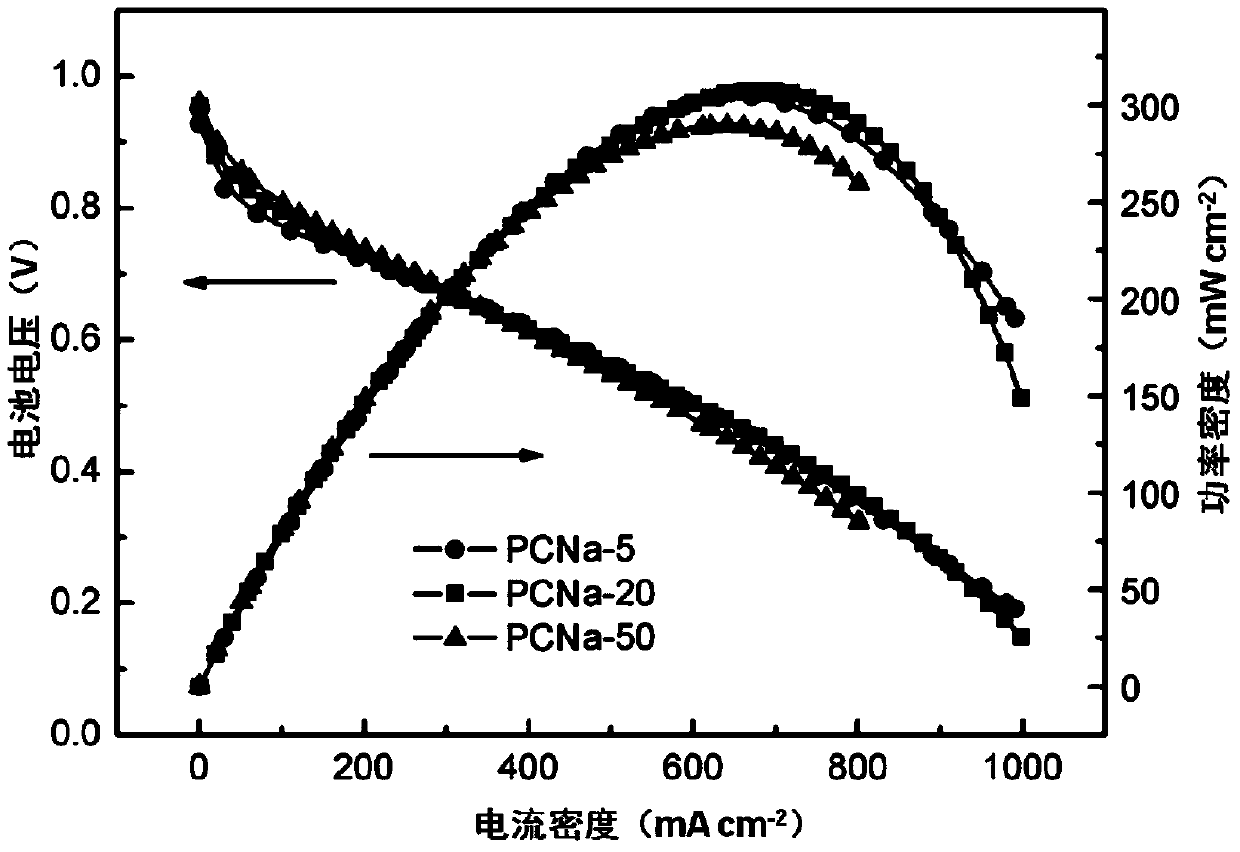

[0060] Example 3, Pt / CNH nanocomposite material (PCNa-20) and its electrocatalytic performance test

[0061] Consistent with the preparation method of Example 1, step 1) is changed to: ultrasonically disperse CNH in ethylene glycol, add 1.96g / L ethylene glycol solution of chloroplatinic acid hexahydrate under stirring, mix well, and then ultrasonically disperse After 30 minutes, a suspension with a CNH concentration of 0.5 g / L and a chloroplatinic acid hexahydrate concentration of 0.392 g / L was obtained, and its pH was ~4.

[0062] After obtaining the Pt / CNH nanocomposite material in the form of black fluffy powder, the platinum loading in the composite material was measured to be 20 wt% by ICP-AES and TGA, and the sample was named PCNa-20.

[0063] 5) Consistent with the electrocatalytic performance test method of Example 1, the performance of the PEMFC single cell using the PCNa-20 nanocomposite material as the electrocatalyst was measured. Platinum loading per unit area is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com