Method for preparing wave-absorbing ceramic component on basis of 3D printing technique

A 3D printing and ceramic technology, applied in the field of wave-absorbing ceramic materials, can solve the problems of poor wave-absorbing effect, high brittleness, difficult industrial application, etc., and achieve good mechanical properties, corrosion resistance, wave-absorbing performance, and reduced thickness , the effect of reducing surface density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

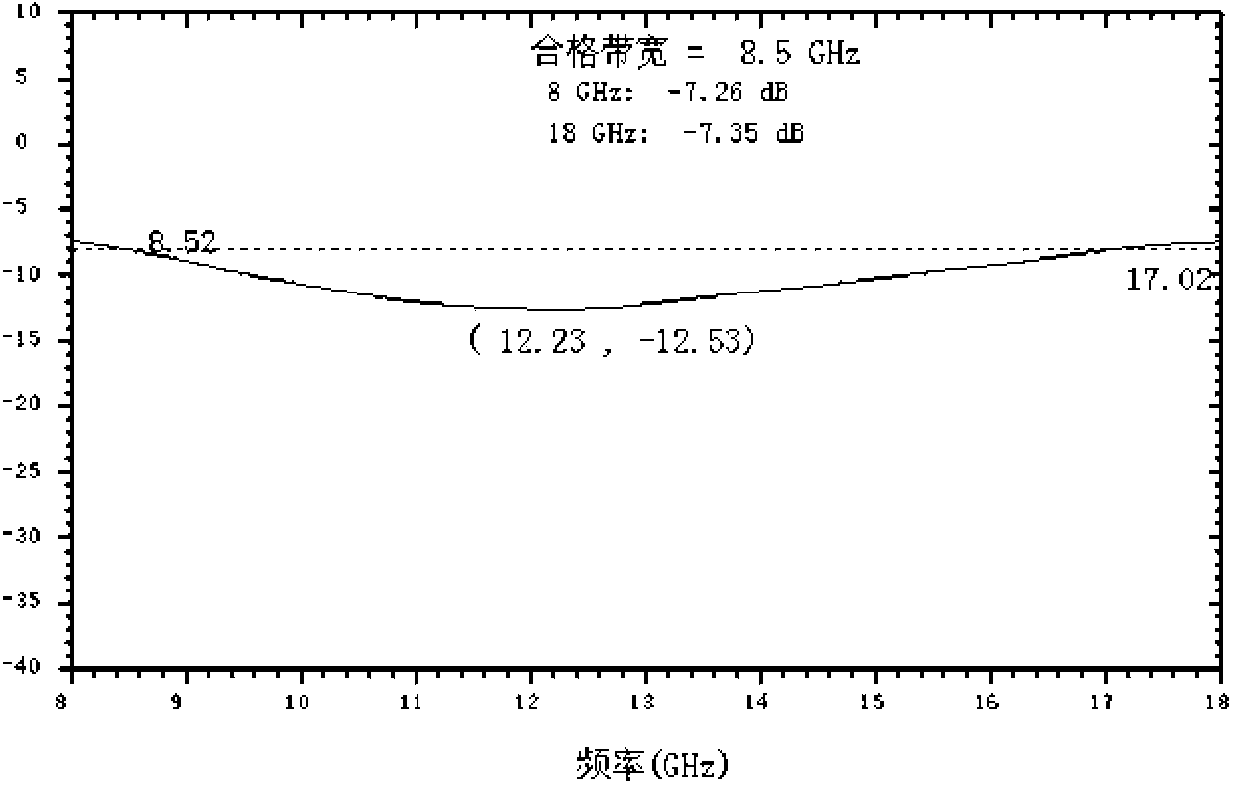

Embodiment 1

[0026] The 3D model of the required wave-absorbing ceramic parts is established in the computer with proE software, and then the computer decomposes the 3D model into a series of two-dimensional sheet models, and the thickness of each sheet is set to 200 μm. Prepare raw materials according to the following volume percentages: 50% silicon carbide powder, 30% nickel powder, and 20% epoxy resin powder. Put the three powders into a specific container and mix them evenly. Pour the evenly mixed powder into the raw material tank of the 3D printer. Perform instrument debugging, set the laser power between 15 and 50 watts, the temperature of the working cylinder at 55°C, and the scanning rate greater than 200m / s. Carry out the pre-powdering operation until the working part is evenly powdered. Multilayer manufacturing begins with computers. After the multi-layer processing is completed, it is naturally cooled, and the remaining powder is carefully removed to obtain the embryo body. T...

Embodiment 2

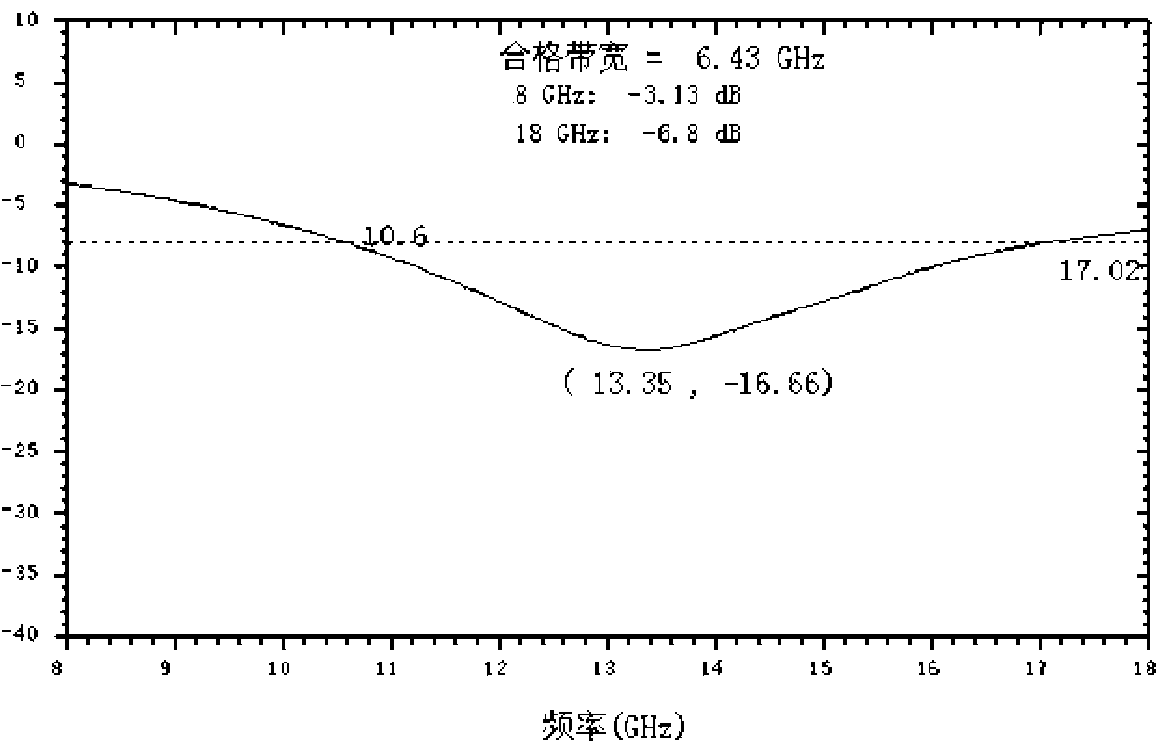

[0028] Establish the 3D model of the required wave-absorbing ceramic components in the computer, and then decompose the 3D model into a series of two-dimensional sheet models by the computer, and the thickness of each sheet is set to 150 μm. Prepare raw materials according to the following volume percentages: 40% boron carbide powder, 30% carbon black powder, and 30% nylon powder. Put the three powders into a specific container and mix evenly. Pour the evenly mixed powder into the raw material tank of the 3D printer. Perform instrument debugging, set the laser power between 170 and 200 watts, the temperature of the working cylinder at 180°C, and the scan rate greater than 200m / s. Carry out the pre-powdering operation until the working part is evenly powdered. Multilayer manufacturing begins with computers. After the multi-layer processing is completed, it is naturally cooled, and the remaining powder is carefully removed to obtain the embryo body. The green body is sintere...

Embodiment 3

[0030] The 3D model of the required wave-absorbing ceramic parts is established in the computer with proE software, and then the computer decomposes the 3D model into a series of two-dimensional sheet models, and the thickness of each sheet is set to 250 μm. Prepare raw materials according to the following volume percentages: 25% aluminum oxide powder, 25% silicon carbide powder, 30% nickel powder, and 20% epoxy resin powder. Put the three powders into a specific container and mix them evenly. Pour the evenly mixed powder into the raw material tank of the 3D printer. Perform instrument debugging, set the laser power between 15 and 50 watts, the temperature of the working cylinder at 55°C, and the scanning rate greater than 200m / s. Carry out the pre-powdering operation until the working part is evenly powdered. Multilayer manufacturing begins with computers. After the multi-layer processing is completed, it is naturally cooled, and the remaining powder is carefully removed to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com