Synthetic method of polystyrene block copolymer for ultramicro filter membrane

A polystyrene block and block copolymer technology, which is applied in the synthesis field of new functional polymer materials, can solve the problems of high pore density, controllable thickness of selective layer, difficulty in preparing regular pore size, etc., and achieves simple implementation steps. , Reduce the purification steps, the effect of low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

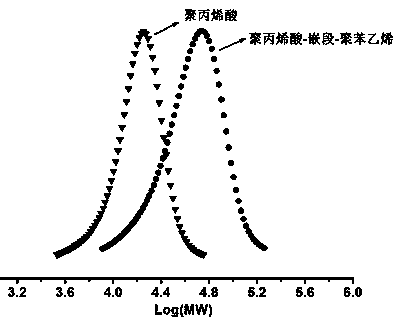

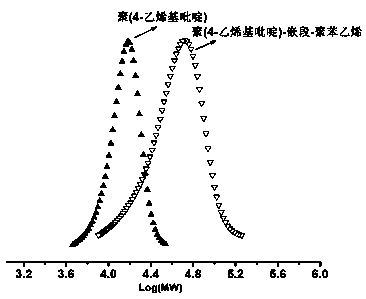

Image

Examples

preparation example Construction

[0027] According to the present invention, a kind of synthetic method of polystyrene block copolymer for ultra-microfiltration membrane comprises the following steps:

[0028] (1) Dissolving the first monomer, initiator and chain transfer agent in solvent A to form a homogeneous solution;

[0029] Wherein, the first monomer is selected from acrylic acid, N-isopropylacrylamide, N,N-dimethylacrylamide, N,N-ethyl dimethacrylate, N-(3-dimethylaminopropyl) Acrylamide, hydroxyethyl acrylate, hydroxyethyl acrylamide, methyl acrylate, ethyl acrylate, butyl acrylate, tert-butyl acrylate, polyethylene glycol acrylate, 4-vinylpyridine, 2-vinylpyridine, Vinylimidazole.

[0030] Described initiator is selected from benzoyl peroxide, azobisisobutyrocyanide, azobiscyanovaleric acid;

[0031] The chain transfer agent is selected from trithioester compounds, and the leaving group (i.e. R group) of the trithioester compound is selected from ethyl, propyl, butyl, pentyl, hexyl, heptyl Base, O...

Embodiment 1

[0041] A kind of synthetic method of polystyrene block copolymer for ultra-microfiltration membrane, the steps are as follows:

[0042](1) Dissolve acrylic acid, azobisisobutylcyanide, and S-dodecyl-S'-(dimethylacetic acid)-trithioester in 3000 ml of dimethylformamide to form a homogeneous solution, in which The molar concentrations of acrylic acid, azobisisobutylcyanide, and S-dodecyl-S'-(dimethylacetic acid)-trithioester were 3 mol / L, 1.5×10 -3 mol / L, 1.5×10 -2 mol / L;

[0043] (2) React the above reaction under a nitrogen atmosphere for 8 hours, and the reaction temperature is 75°C;

[0044] (3) Then add 25mol styrene monomer that has been pre-deoxygenated;

[0045] (4) Keep the nitrogen atmosphere unchanged, raise the reaction temperature to 80°C and continue the reaction for 36 hours, then stop the reaction and cool to room temperature naturally;

[0046] (5) Precipitate the reaction solution to 3×10 4 ml of petroleum ether, the solid product was isolated as a two-b...

Embodiment 2

[0048] A kind of synthetic method of polystyrene block copolymer for ultra-microfiltration membrane, the steps are as follows:

[0049] (1) Dissolve acrylic acid, benzoyl peroxide, and S-dodecyl-S'-(dimethylacetic acid)-trithioester in 1000 ml of dimethylformamide to form a homogeneous solution, in which acrylic acid , benzoyl peroxide, and S-dodecyl-S'-(dimethylacetic acid)-trithioester have a molar concentration of 3 mol / L, 1.5×10 -3 mol / L, 1.5×10 -2 mol / L;

[0050] (2) React the above reaction under a nitrogen atmosphere for 8 hours, and the reaction temperature is 75°C;

[0051] (3) Then add 25 mol of pre-deoxygenated styrene and 5 mol of pre-deoxygenated butyl acrylate;

[0052] (4) Keep the nitrogen atmosphere unchanged, raise the reaction temperature to 85°C and continue the reaction for 30 h, then stop the reaction and cool to room temperature naturally;

[0053] (5) Precipitate the reaction solution into 8000ml of isopropanol, and separate the solid product as a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com