Carbon electrode modified by cerium-zirconium oxide, preparation method and flow battery

A cerium zirconium oxide, flow battery technology, which is applied to batteries with bipolar electrodes, fuel cells, battery electrodes, etc. Low cost, good stability, easy to achieve the effect of large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0033] (1) 50.4mg cerous nitrate (Ce(NO 3 ) 3 ·6H 2O) Dissolve in 25mL of deionized water, and fully ultrasonically disperse at 25°C for 3min to make a homogeneous solution.

[0034] (2) Let the homogeneous solution prepared in step (1) stand for 5 minutes to remove air bubbles and impurities.

[0035] (3) Cut the pretreated polyacrylonitrile-based graphite felt into the required size, put it in the solution prepared in step (2) and disperse it ultrasonically for 5 minutes, slowly add 2.3mL of ammonia water dropwise under the condition of magnetic stirring, adjust pH=8, and let stand for 30min.

[0036] (4) Place the graphite felt prepared in step (3) in a blast drying oven at 70°C for 12 hours, cool to room temperature and then place it in a nitrogen atmosphere for calcination at 600°C for 2 hours. The prepared sample is recorded as 0.5% CeO 2 / GF. Of which 0.5% CeO 2 The meaning of / GF is as follows: the mass percentage of ceria-modified graphite felt is 0.5%. In the ...

example 2

[0038] Using 69.6mg of zirconium nitrate (Zr(NO 3 ) 4 ·5H 2 O) be dissolved in 25mL deionized water, preparation method is the same as example 1, makes 0.5%ZrO 2 / GF carbon electrode.

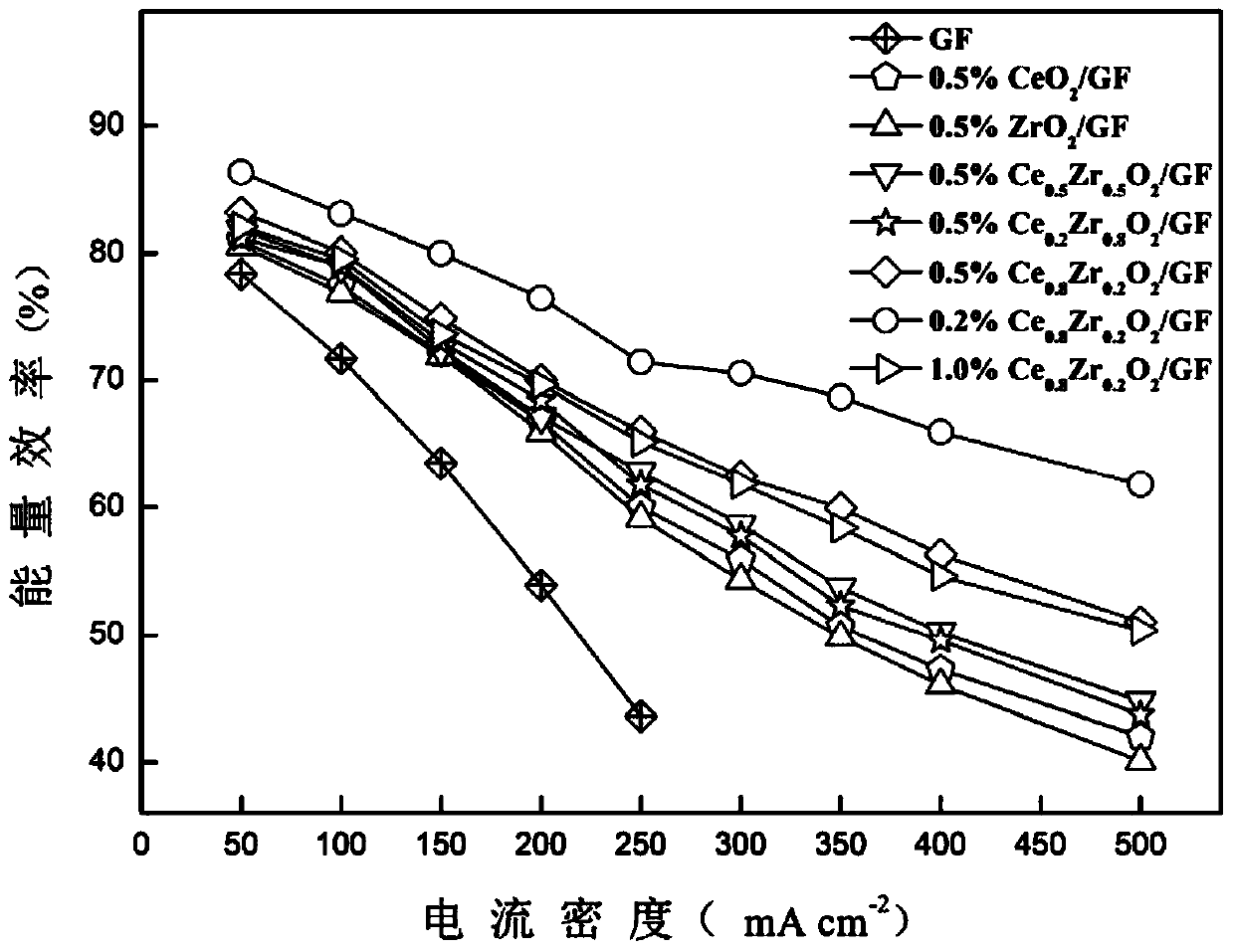

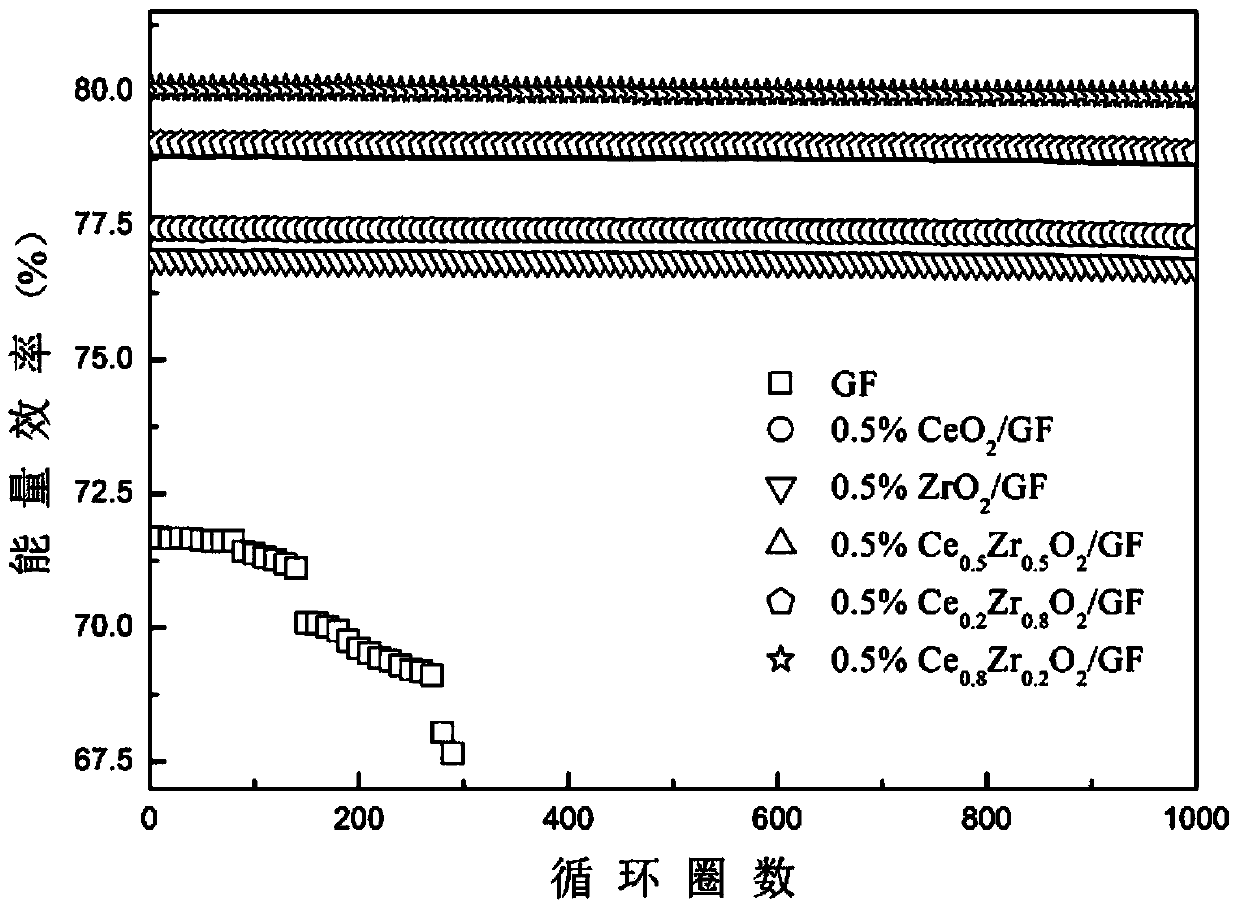

[0039] With the 0.5% ZrO 2 / GF carbon electrode assembly vanadium redox flow battery, other assembly conditions and test conditions are the same as Example 1. In the charge and discharge experiment, the battery charge and discharge current density is 100mA cm -2 , the energy efficiency of the battery is 76.9%; when the battery charge and discharge current density is 300mA cm -2 , the energy efficiency of the battery is 54.3%; when the battery charge and discharge current density is 500mA cm -2 , the energy efficiency of the battery is 40.1% (such as figure 1 shown). In the charge-discharge cycle life experiment, when the battery charge-discharge current density is 100mA cm -2 , after 1000 cycles of charging and discharging, the energy efficiency of the battery remains at about 76.8%, b...

example 3

[0041] Using 29.4mg of cerous nitrate (Ce(NO 3 ) 3 ·6H 2 O), 29.1mg of zirconium nitrate (Zr(NO 3 ) 4 ·5H 2 O) be dissolved in 25mL deionized water, preparation method is the same as example 1, makes 0.5%Ce 0.5 Zr 0.5 o 2 / GF carbon electrode.

[0042] With the 0.5% Ce 0.5 Zr 0.5 o 2 / GF carbon electrode assembly vanadium redox flow battery, other assembly conditions and test conditions are the same as Example 1. In the charge and discharge experiment, the battery charge and discharge current density is 100mA cm -2 , the energy efficiency of the battery is 78.9%; when the battery charge and discharge current density is 300mA cm -2 , the energy efficiency of the battery is 58.6%; when the battery charge and discharge current density is 500mA cm -2 , the energy efficiency of the battery is 40.8% (such as figure 1 shown). In the charge-discharge cycle life experiment, when the battery charge-discharge current density is 100mA cm -2 , after 1000 cycles of charging ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com