Compound having acridan ring structure and organic electroluminescent element

A technology of dihydroacridine and compounds, applied in the field of organic electroluminescent devices, can solve the problems of insufficient current efficiency, problems of amorphousness, and low driving voltage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0121]

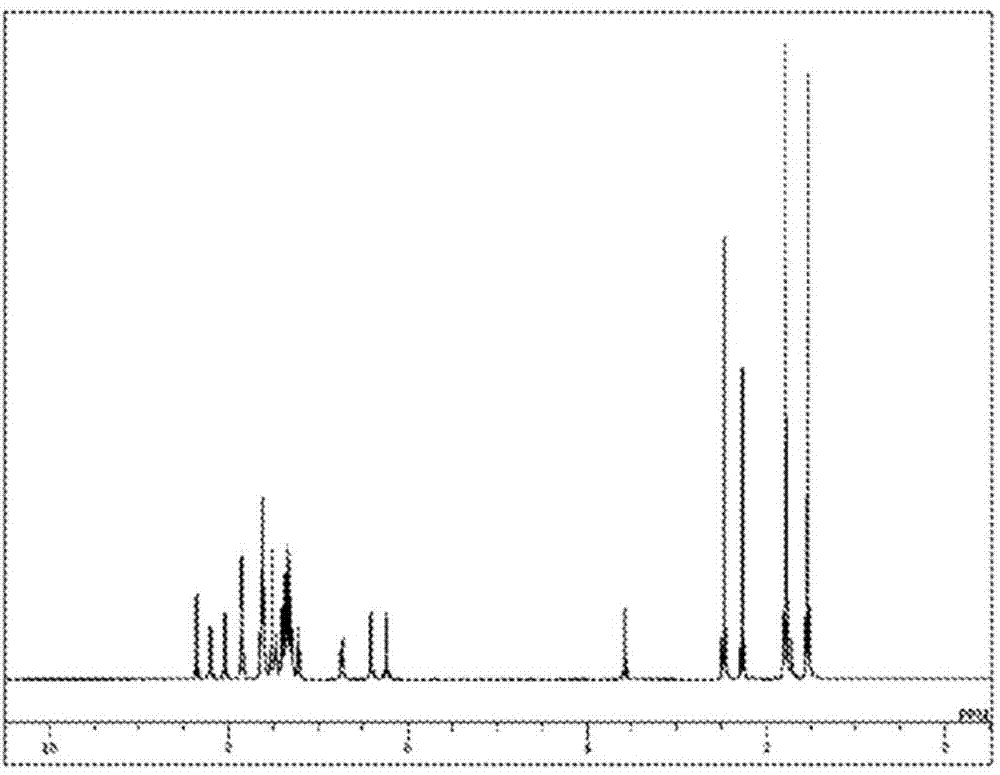

[0122] Under nitrogen atmosphere, add 7-bromo-10-(9,9-dimethyl-9H-fluoren-2-yl)-2,9,9-trimethyl-9,10-dihydro to the reaction vessel Acridine 5.27g, 9-phenyl-3-(4,4,5,5-tetramethyl-[1,3,2]dioxaborolin-2-yl)-9H-carbazole 4.70g, Toluene 79ml, ethanol 20ml, 2M potassium carbonate aqueous solution 8ml, nitrogen gas was passed for 30 minutes while irradiating ultrasonic waves. 0.24 g of tetrakis(triphenylphosphine)palladium was added, heated, and stirred at 67° C. for 5 hours. After naturally cooling to room temperature, 50 ml of toluene was added, and the organic layer was collected by liquid separation. The organic layer was washed with 50 ml of water, dried over anhydrous magnesium sulfate, and concentrated under reduced pressure to obtain a crude product. The crude product was purified by column chromatography (carrier: silica gel, eluent: hexane / toluene). Next, after repeating crystallization in a mixed solvent of toluene and diisopropyl ether and crystallization ...

Embodiment 2

[0126]

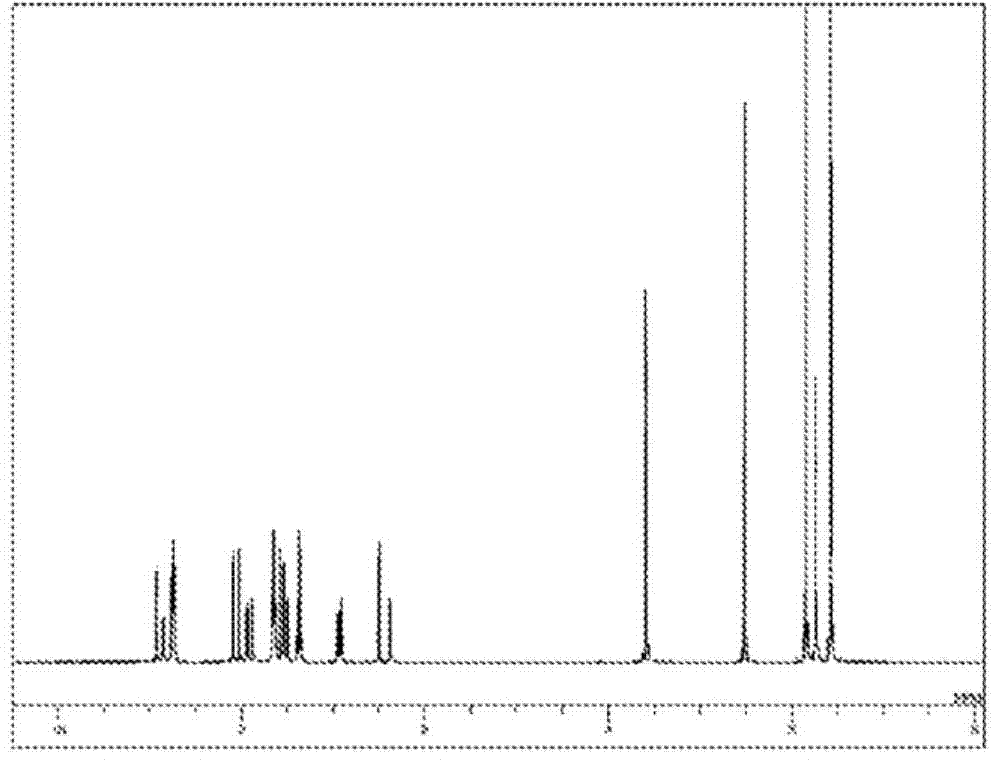

[0127] Under nitrogen atmosphere, add 2-bromo-10-(9,9-dimethyl-9H-fluoren-2-yl)-9,9-dimethyl-9,10-dihydroacridine to the reaction vessel 7.00g, 4,4,5,5-tetramethyl-2-(triphenylene-2-yl)-[1,3,2]dioxaborane 5.16g, tetrakis(triphenylphosphine)palladium 0.34 g, 4.03 g of potassium carbonate, 40 ml of toluene, 10 ml of ethanol, and 15 ml of water were heated and stirred under reflux for 3 hours. Naturally cooled to room temperature, water and toluene were added, and the organic layer was collected by liquid separation. The organic layer was dried over anhydrous magnesium sulfate, and concentrated under reduced pressure to obtain a crude product. The crude product was purified by column chromatography (carrier: silica gel, eluent: toluene / hexane=1 / 1) to obtain 10-(9,9-dimethyl-9H-fluoren-2-yl)- 5.40 g of white powder of 9,9-dimethyl-2-(triphenylene-2-yl)-9,10-dihydroacridine (compound 71) (yield 59%).

[0128] For the obtained white powder, structure identification was...

Embodiment 3

[0131] Synthesis of

[0132] Under a nitrogen atmosphere, 11.0 g of 1-bromo-4-(dibenzofuran-2-yl)benzene, 4,4,5,5-tetramethyl-2-(10-phenyl- 2,9,9-trimethyl-9,10-dihydroacridin-7-yl)-[1,3,2]dioxaborane 17.3g, tetrakis(triphenylphosphine)palladium 0.78g, 7.05 g of potassium carbonate, 110 ml of toluene, 18 ml of ethanol, and 25 ml of water were heated and stirred under reflux for 6.5 hours. Naturally cooled to room temperature, water and toluene were added, and the organic layer was collected by liquid separation. The organic layer was dried over anhydrous magnesium sulfate, and concentrated under reduced pressure to obtain a crude product. The crude product was purified by column chromatography (carrier: silica gel, eluent: toluene / heptane=1 / 4) to obtain 2-[(dibenzofuran-2-yl)benzene-4-yl)- 13.2 g of white powder of 7,9,9-trimethyl-10-phenyl-9,10-acridine (compound 80) (yield 71%).

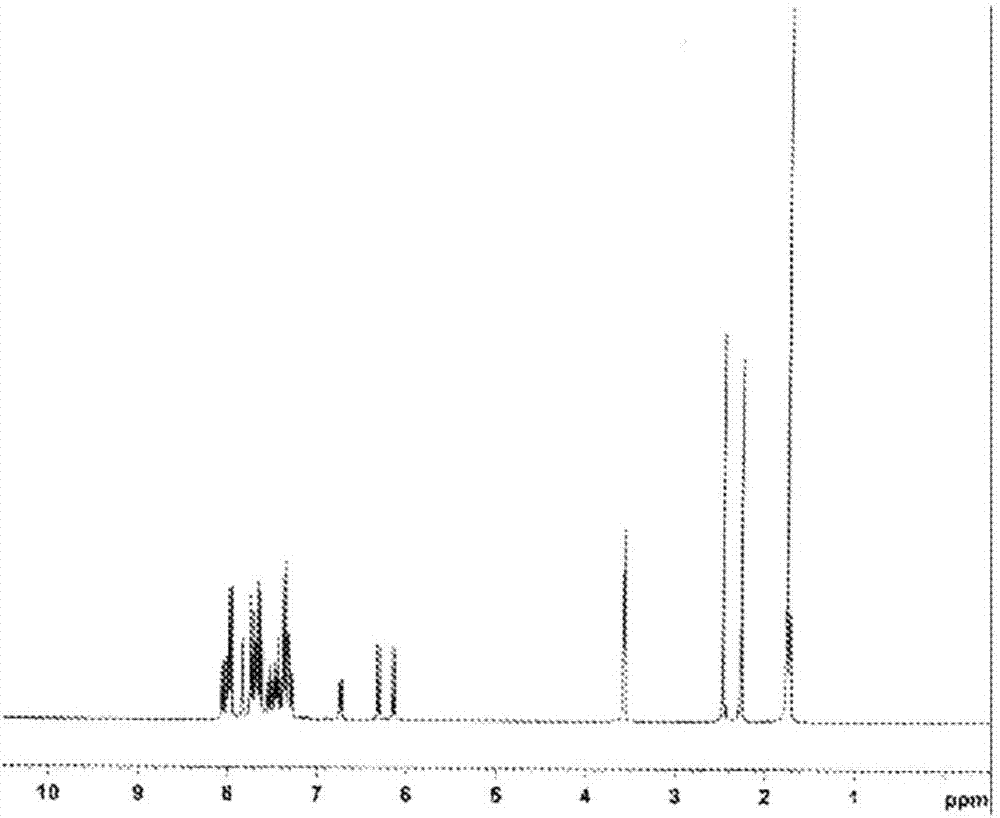

[0133] For the obtained white powder, structure identification was carried out using NMR. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com