Preparation method of monodisperse fluorescent microspheres

A fluorescent microsphere, monodisperse technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of large amount of fluorescent substances added, complicated preparation process, etc., and achieve simple and easy operation, strong chemical stability, and high fluorescence intensity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

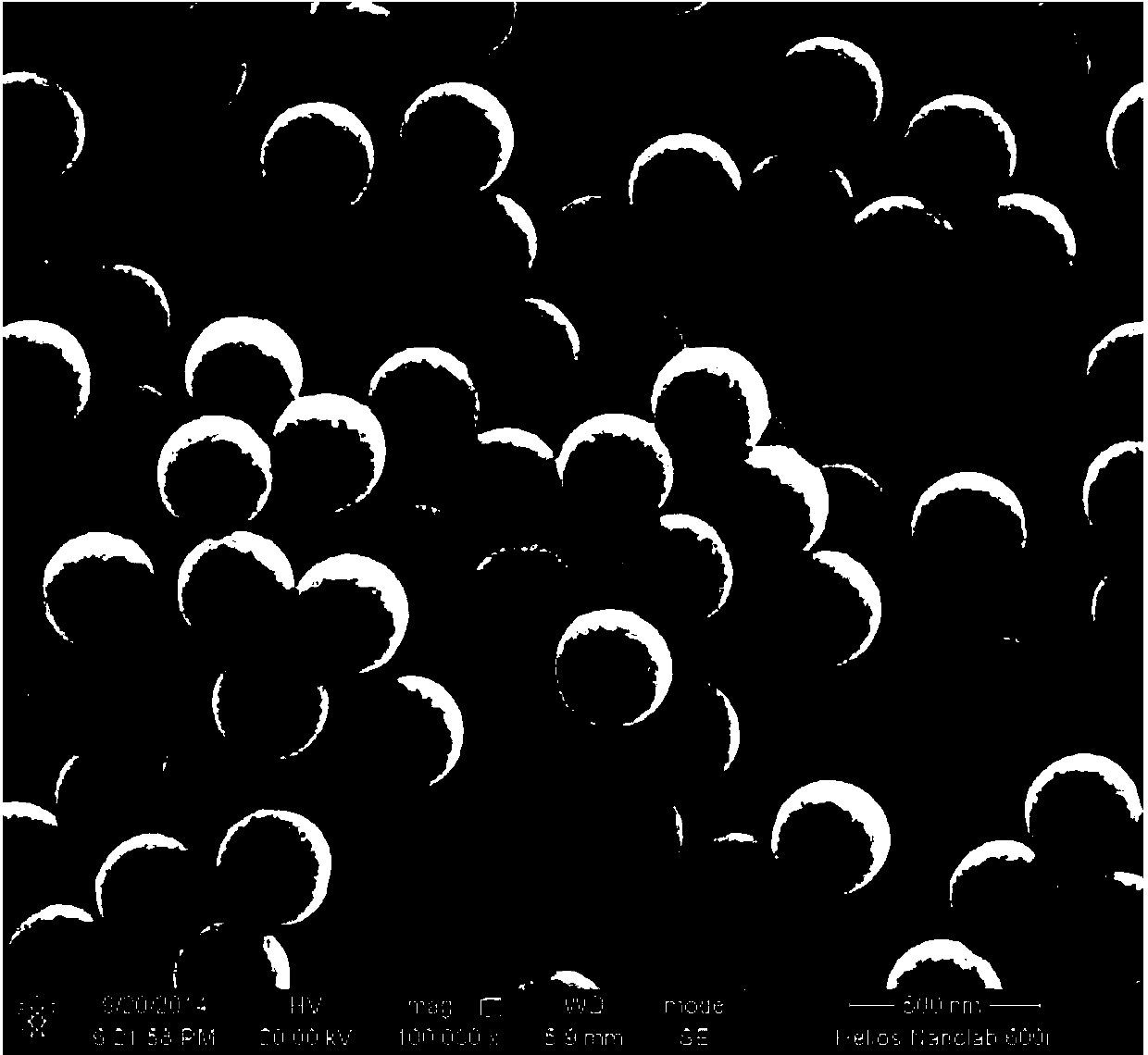

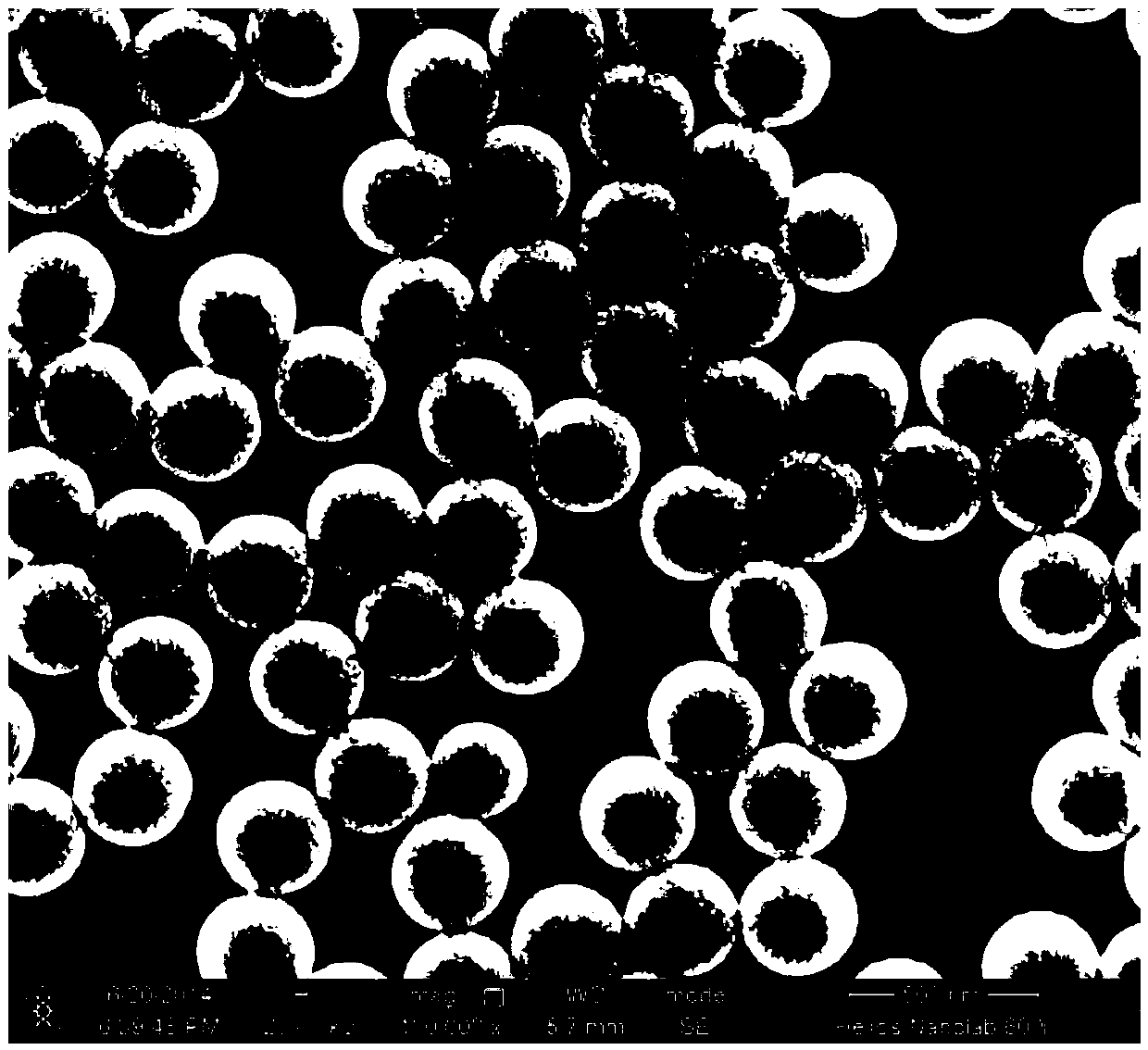

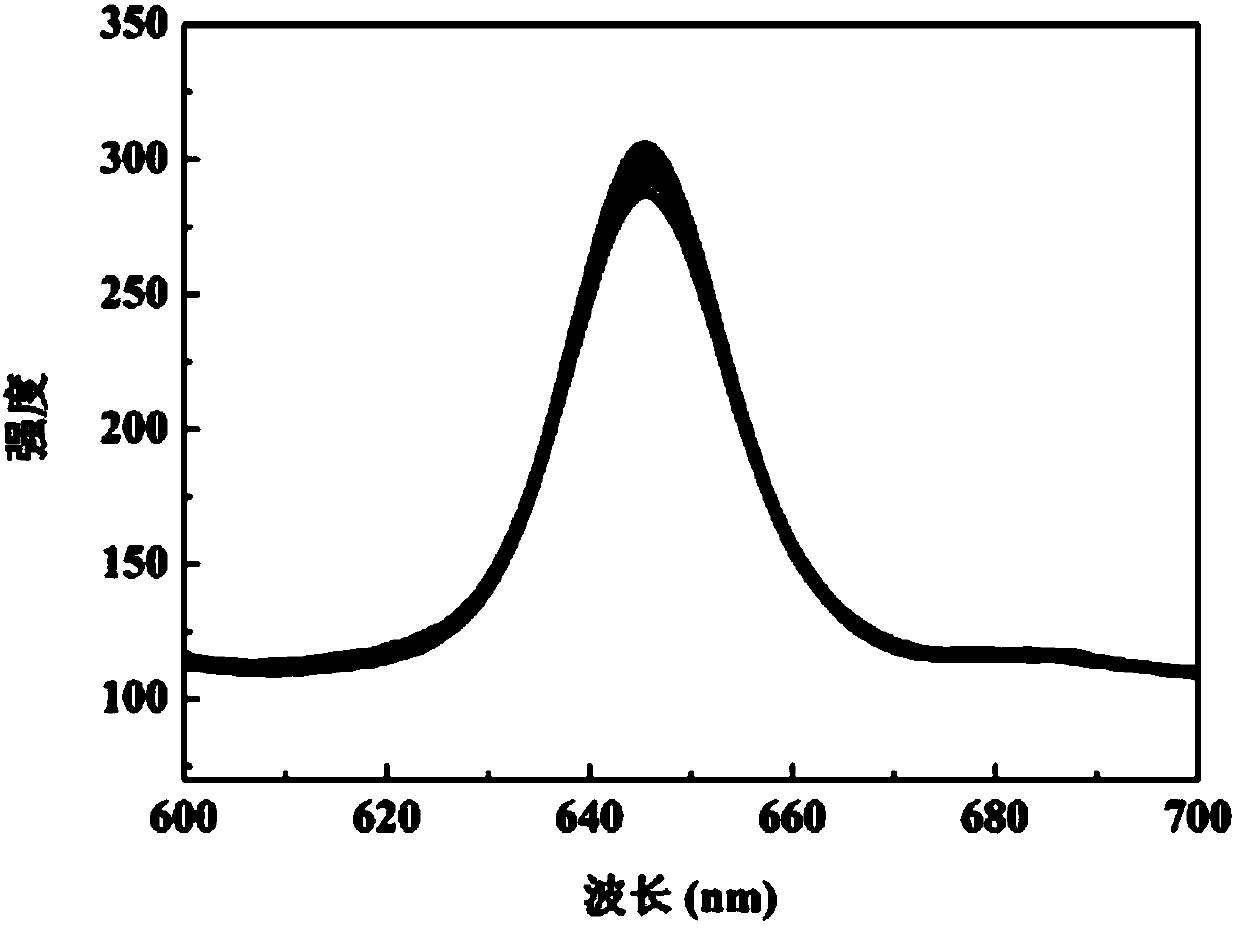

[0024] Specific embodiment one: the preparation method of a kind of monodisperse fluorescent microsphere of this embodiment is carried out according to the following steps:

[0025] 1. Preparation of polystyrene microspheres: Ultrasonicate the glass reactor with acetone, methanol and pure water for 15-20 minutes, then dry it, then add 100-200 mL of ultra-pure water, stir mechanically at 300-400 rpm, and maintain a nitrogen atmosphere, 20 Add 3~10mL of styrene monomer after ~30min, add 8~10mL of 1% potassium persulfate after stirring for 15~20min, then set the speed at 400~500rpm, condense and reflux at a temperature of 60~80°C for 12 ~24 hours to obtain polystyrene microspheres;

[0026] 2. Preparation of fluorescent indicator solution: the concentration of 6-8mg was 1×10 -3 ~1×10 -6 The mol / L fluorescent indicator is evenly dispersed in 10-20mL of organic solvent to prepare a fluorescent indicator solution;

[0027] 3. Preparation of fluorescent microspheres by swelling me...

specific Embodiment approach 2

[0034] Embodiment 2: This embodiment is different from Embodiment 1 in that: in step 1, mechanical stirring is performed at 400 rpm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the temperature is 70° C. and the reaction is refluxed for 24 hours. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com