Microbial oil preparation method with biodiesel byproducts as carbon sources

A microbial oil and biodiesel technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of expensive raw materials of biodiesel and expensive cost of microbial oil, achieve short preparation cycle, reduce preparation cost, The effect of large application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

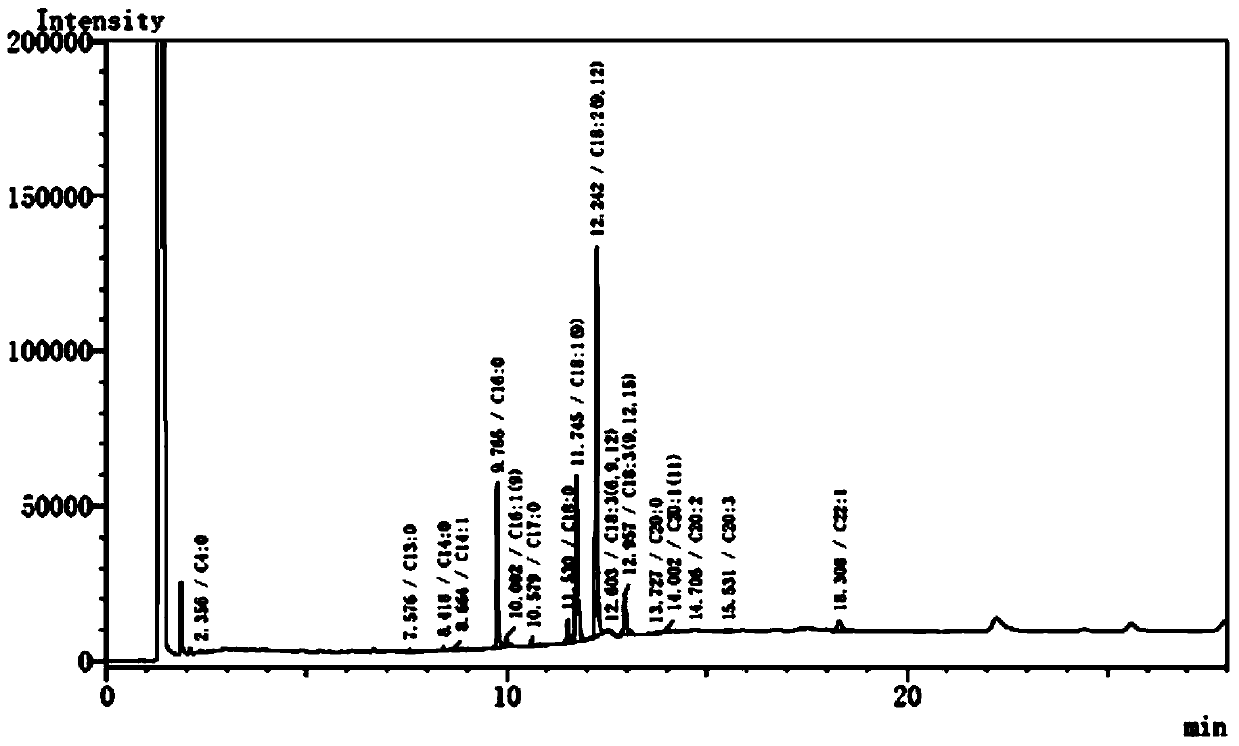

Image

Examples

Embodiment 1

[0032] The above inoculum was added to the sterilized medium at a ratio of 10% and cultivated for 7 days, the pH of the medium was 6.0, the sterilization temperature was 121°C, the sterilization time was 30 minutes, the shaker speed was 200r / min, crude glycerol Ingredients: 27% glycerin, 18% methanol, 10% ethanol, 45% water. Medium composition: crude glycerol 27g / L (to ensure that the carbon content in the medium is consistent with 20g / L glucose), NH 4 SO 4 5g / L, KH 2 PO 4 1g / L, yeast extract powder 0.5g / L, Mg 2 SO 4 0.5g / L. The rest of the experimental conditions and steps are the same as in Comparative Example 1. At this time, the dry weight of the cells was measured to be 20.5 g / L, and the oil content in the dry weight of the cells was 47.8%.

[0033] From Comparative Example 1, Comparative Example 2 and Example 1, it can be seen that the dry cell weight and oil yield of microbial oils prepared with crude glycerol as carbon source are higher than those of cells when ...

Embodiment 2

[0035] The inoculum was added to the sterilized medium at a ratio of 5% and cultivated for 6 days, the pH was 5.8, the sterilization temperature was 121°C, the sterilization time was 30 minutes, the shaker speed was 180r / min, and the crude glycerin composition: glycerol 25%, methanol 25%, ethanol 15%, water 30%, fatty acid sodium 2%, fatty acid ester 1%, NaCl 2%. Crude glycerol medium composition: crude glycerol 100g / L, NH 4 SO 4 5g / L, KH 2 PO 4 1g / L, yeast extract powder 0.5g / L, Mg 2 SO 4 0.5g / L. Put 32489 5ml of Rhodotorula viscosus obtained after fermentation in a centrifuge, centrifuge at 4000r / min for 30 minutes, take the lower layer of bacteria and put them in an oven, and dry them at 65°C until they reach a constant weight. At this time, the dry weight of the cells was measured to be 16.5 g / L. Put the dried Rhodotorula viscosus 32489 into a centrifuge tube, add 10ml of 4mol / L hydrochloric acid to the dried bacteria, place the shaker to mix well, leave it at room ...

Embodiment 3

[0037] Add the inoculum to the sterilized medium at a ratio of 10% and cultivate for 10 days, the pH is 6.0, the sterilization temperature is 121°C, the sterilization time is 30 minutes, the shaker speed is 220r / min, and the crude glycerin composition: glycerol 45%, methanol 15%, ethanol 5%, water 31%, fatty acid sodium 1%, fatty acid ester 2%, NaCl 1%. Crude glycerol medium composition: crude glycerol 20g / L, NH 4 SO 4 5g / L, KH 2 PO 4 1g / L, yeast extract powder 0.5g / L, Mg 2 SO 4 0.5g / L. Take 32489 5ml of Rhodotorula viscosus obtained after fermentation and put it in a centrifuge, centrifuge at 4000r / min for 30 minutes, take the lower layer of bacteria and put them in an oven, and dry them at 45°C until they reach a constant weight. At this time, the dry weight of the cells was measured to be 13.5 g / L. Put the dried Rhodotorula viscosus 32489 into a centrifuge tube, add 10ml of 4mol / L hydrochloric acid to the dried cells, place the shaker to mix well, leave it at room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com