Preparation method for graphene field emitting cathode, and graphene field emitting cathode

A technology of emitting cathode and graphene, applied in the field emission field, can solve the problems of easily damaged graphene structure, field emission current decay, small field emission current, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

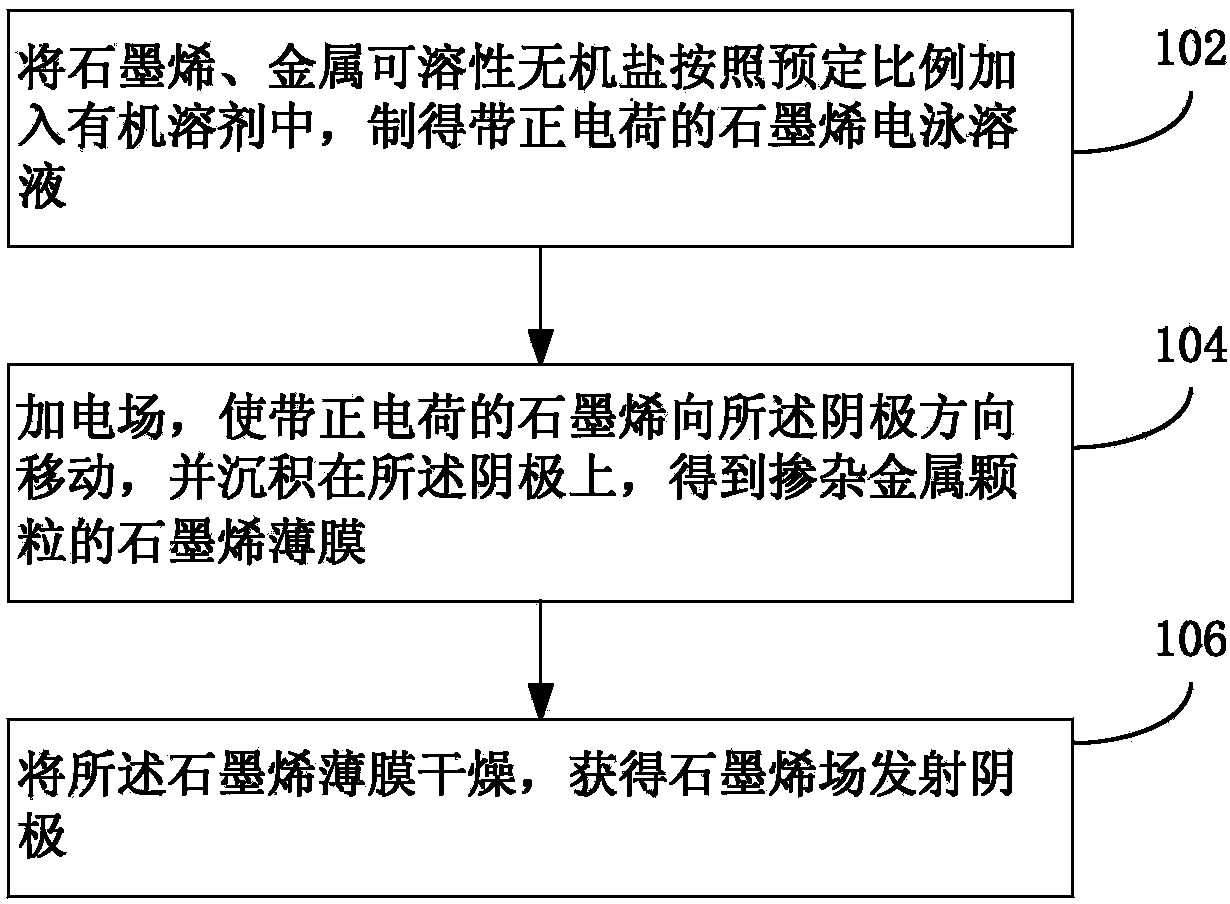

[0025] Such as figure 1 Shown, the graphene field emission cathode preparation method of the present application, an embodiment thereof, comprises the following steps:

[0026] Step 102: Prepare graphene electrophoresis solution.

[0027] Graphene and metal soluble inorganic salts (charge additives) are added to the organic solvent according to a predetermined ratio, and ultrasonically dispersed to prepare a uniform and stable graphene electrophoresis solution.

[0028] Graphene includes single-layer graphene, multi-layer graphene or a mixture of single-layer graphene and multi-layer graphene. The lateral size of graphene is preferably 500 nm-10 μm, and it can be prepared by chemical vapor deposition or chemical exfoliation (Hummer method). The metal soluble inorganic salts include one or more mixtures of soluble inorganic salts of copper, silver, gold and platinum. In one embodiment, the metal-soluble inorganic salt specifically includes copper nitrate, cuprous nitrate, si...

Embodiment 1

[0045] Graphene prepared by the chemical exfoliation method with a lateral size of 0.5-3μm and a thickness of 0.5-3.7nm is added to absolute ethanol, and 10% Cu(NO3)2 (based on graphene weight) is added, and the graphene concentration is 0.05mg / ml , using an ultrasonic cell disruptor to ultrasonically disperse for 30 minutes to obtain a uniform and stable graphene electrophoresis solution;

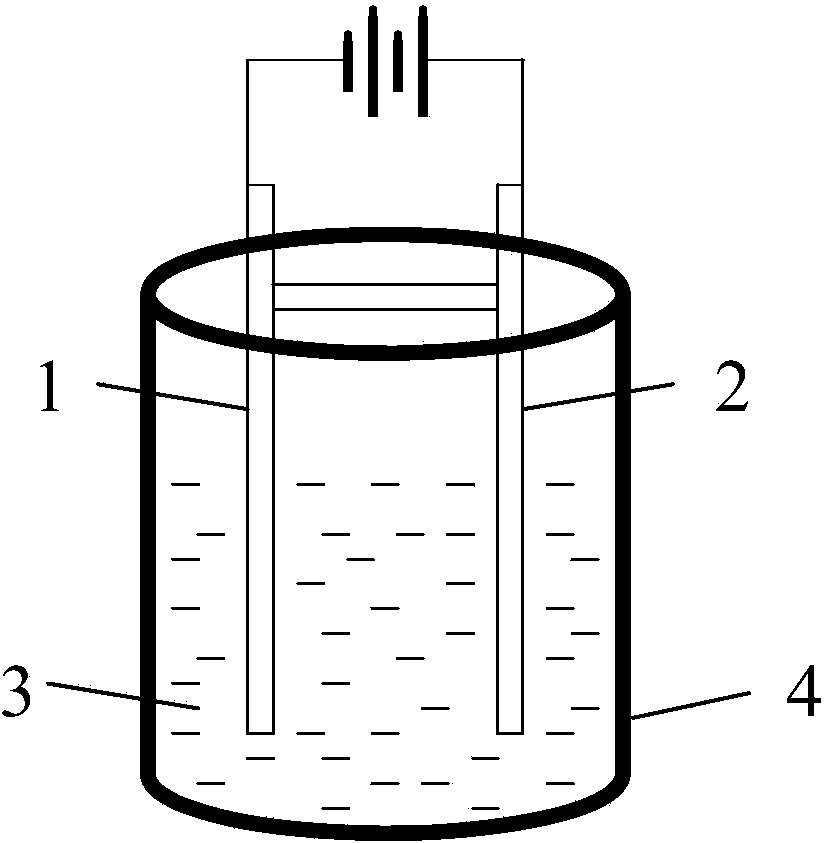

[0046] Select ITO conductive glass and oxygen-free copper sheet as electrodes, clean them with acetone and ethanol for 10 minutes ultrasonically, and dry them with N2 before use. Then, the ITO conductive glass was used as the cathode, and the oxygen-free copper sheet was used as the anode, inserted into the graphene solution, the distance between the cathode and the anode was 1 cm, the DC electrophoresis voltage was 100 V, and the electrophoresis time was 5 min. Graphene film.

[0047] The graphene film was vacuum-dried at 60° C. for 30 min to obtain a graphene field emission cathode.

Embodiment 2

[0049] Add the graphene prepared by the chemical exfoliation method with a lateral size of 0.5-3μm and a thickness of 0.5-3.7nm into isopropanol, add 50% AgNO3 (based on the weight of graphene), and the graphene concentration is 1mg / ml, and use ultrasonic cell disruption Machine ultrasonic dispersion for 2 hours to obtain a uniform and stable graphene electrophoresis solution;

[0050] Select ITO conductive glass and nickel sheet as electrodes, clean them ultrasonically with acetone and ethanol for 10 min, and dry them with N2 before use. Then, the ITO conductive glass was used as the cathode, the nickel sheet was used as the anode, inserted into the graphene solution, the distance between the cathode and the anode was 0.1cm, the DC electrophoresis voltage was 200V, and the electrophoresis time was 30s, and graphite doped with Ag nanoparticles was prepared on the ITO substrate. vinyl film.

[0051] The graphene film was vacuum-dried at 120° C. for 2 h to obtain a graphene fie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com