Vanadium-based SCR catalyst and preparation method thereof

An SCR catalyst and catalyst technology, applied in the chemical field, can solve problems such as poor hydrothermal durability and catalyst durability, and achieve the effects of ensuring high temperature durability, maintaining hydrothermal durability, and suppressing specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

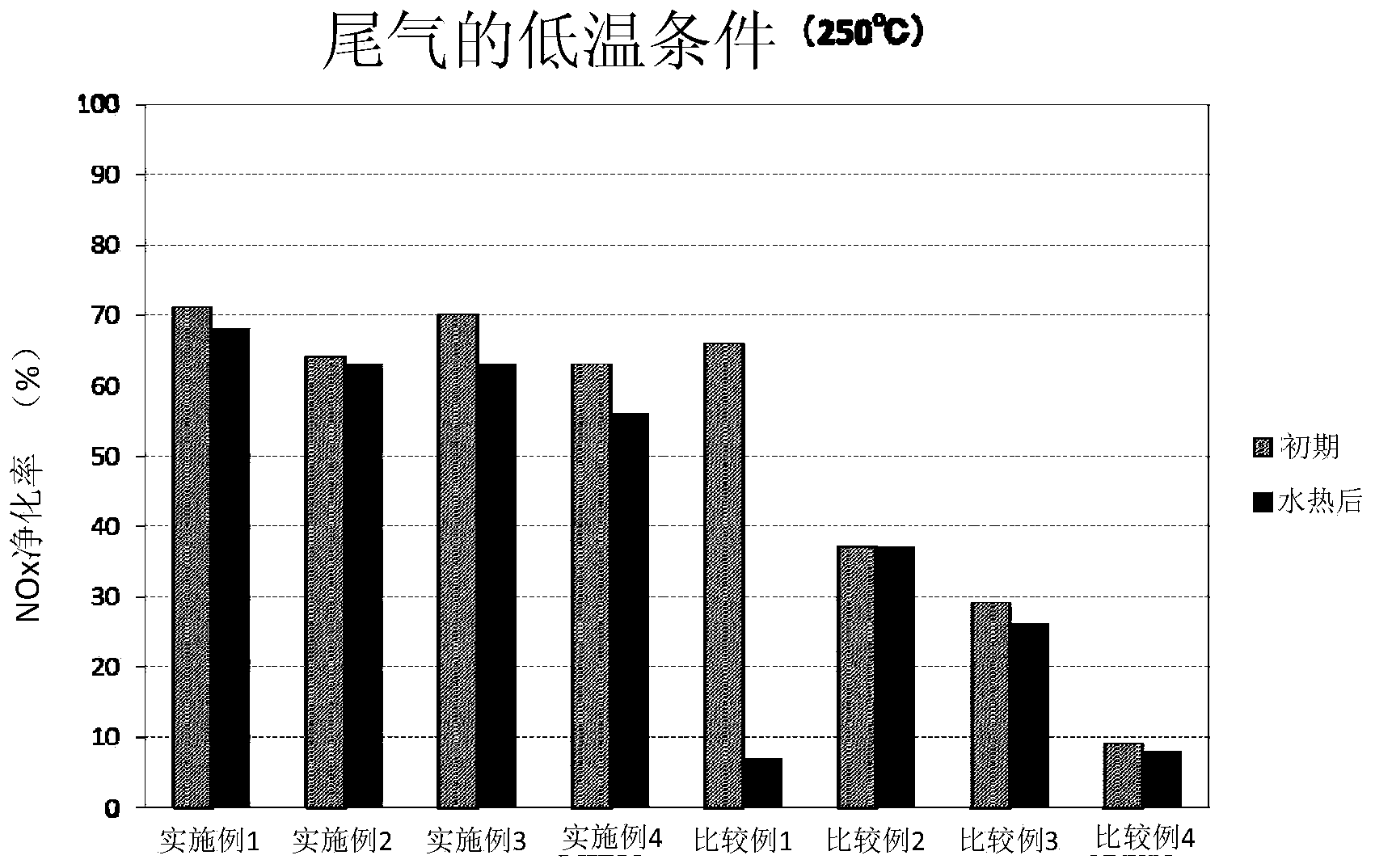

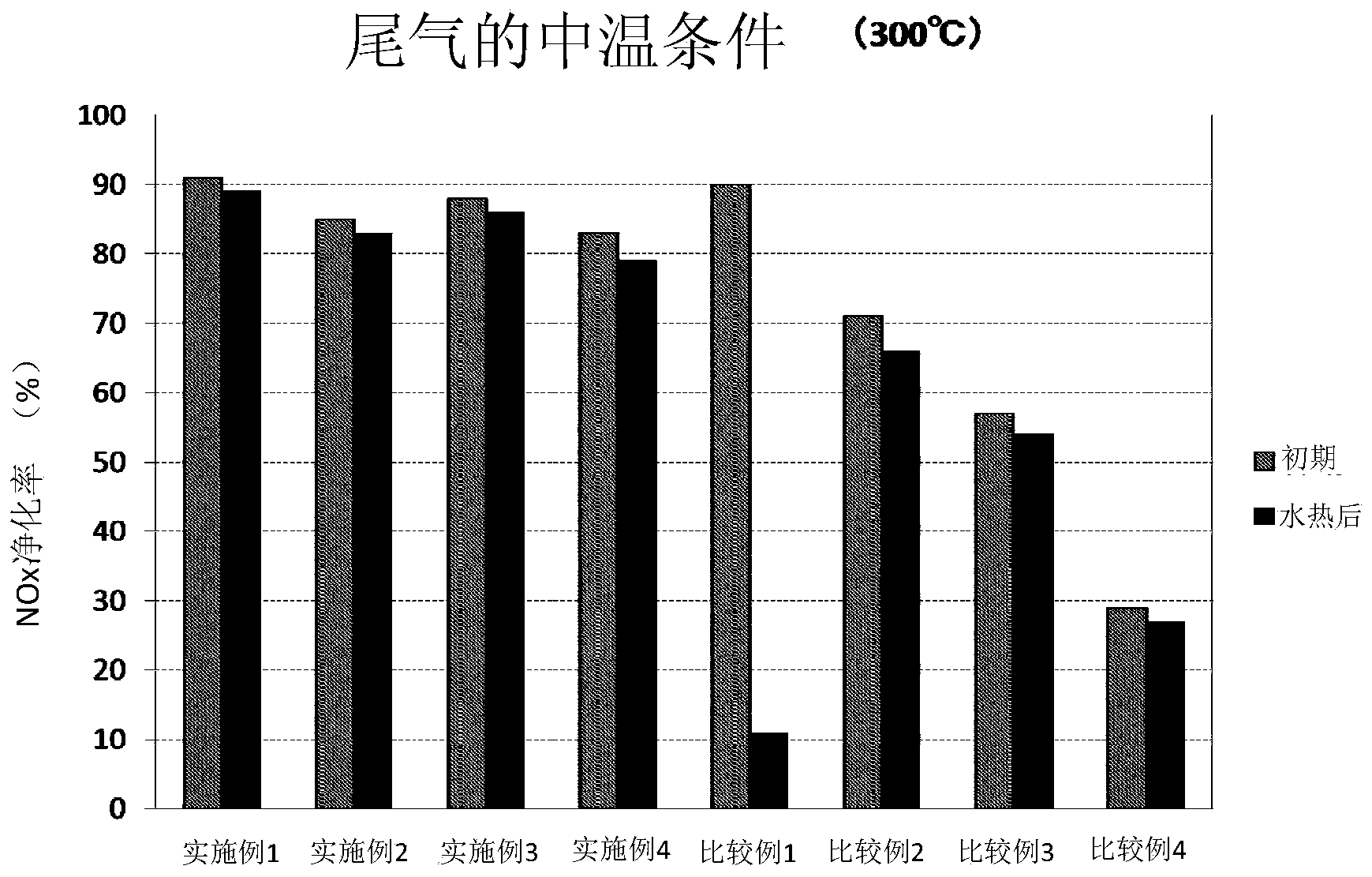

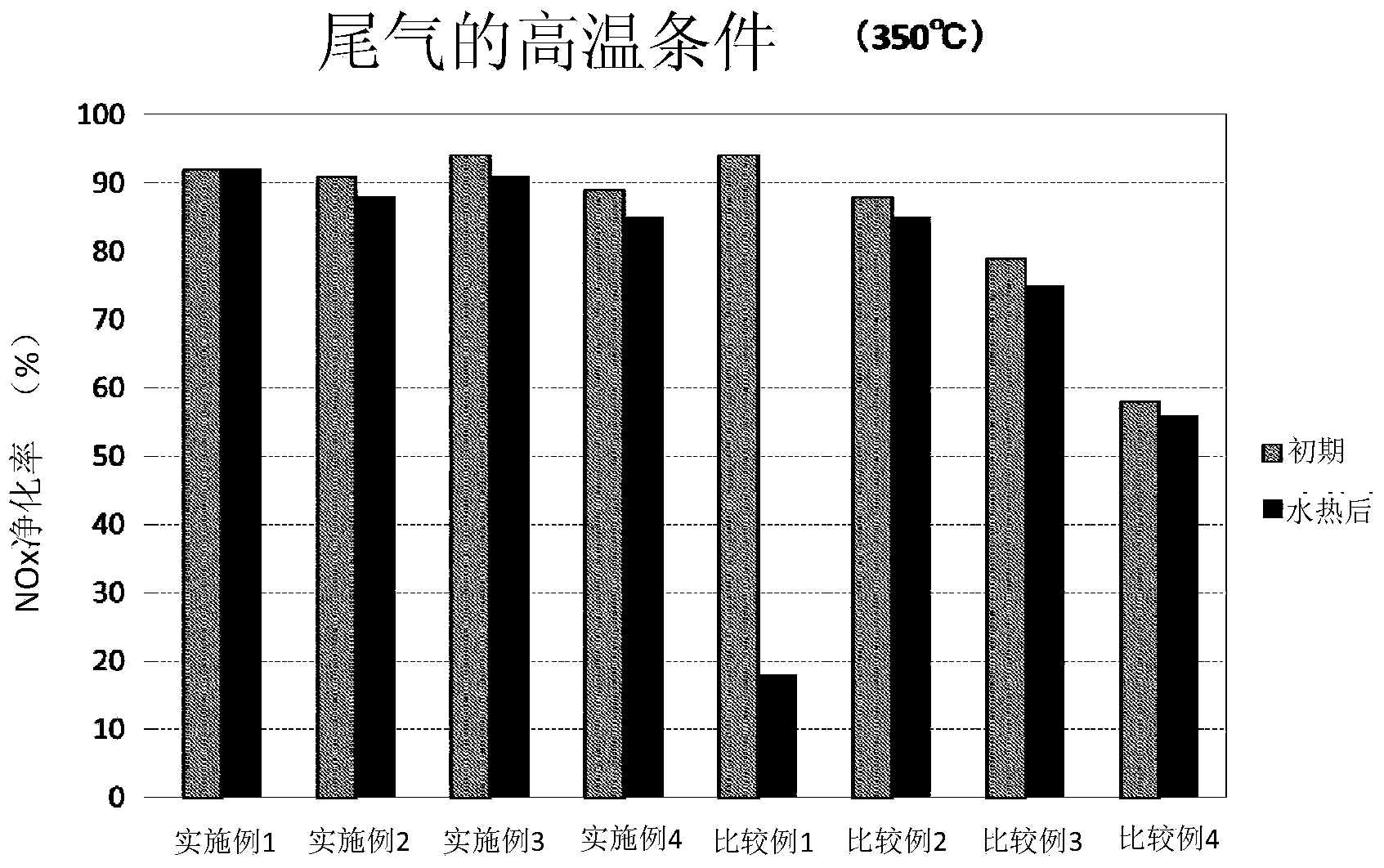

Examples

Embodiment 1

[0051] Embodiment 1 is to use anatase type porous titanium dioxide as carrier, after loading ammonium sulfate, load V 2 o 5 and WO 3 catalyst.

[0052] 1.1 Preparation of anatase-type porous titanium dioxide hydrated colloid

[0053] Mix 100 g of titanyl sulfate and 10% sodium hydroxide by mass, titrate into 1 L of ion-exchanged water for 1 hour, and stir to keep the pH value between 2.5 and 3.5. Then, water washing and filtration are repeated to make the pH value reach 5-6, and the obtained coagulation is dried at 180° C. to obtain a hydrated colloid.

[0054] 1.2 Treatment of ammonium sulfate

[0055] Next, 2.5 g of ammonium sulfate was dissolved by adding 43 g of ion-exchanged water, and this ammonium sulfate aqueous solution and 43 g of the above-mentioned titanium dioxide hydrogel were sufficiently kneaded in a magnetic mortar. The kneaded material was degassed in a vacuum furnace at a vacuum pressure of 4 to 7 Torr without heating. Then, it was dried at 120° C., an...

Embodiment 2

[0061] Embodiment 2 is to use the specific surface area with embodiment 1, and the anatase type titanium dioxide that catalyst forms is different is carrier, loads ammonium sulfate, stacks V then 2 o 5 and WO 3 catalyst.

[0062] 2.1 Preparation of anatase-type porous titanium dioxide hydrated colloid

[0063] Mix 100 g of titanyl sulfate and 10% sodium hydroxide by mass, titrate into 1 L of deionized water for 1 hour, and stir to keep the pH value between 2 and 3. Then, washing with water and filtering are repeated to make the pH value reach 5-6, and the obtained gel is dried at 180° C. to obtain the desired xerogel.

[0064] 2.2 Treatment of ammonium sulfate

[0065] Add 43 g of deionized water to 2.5 g of ammonium sulfate to dissolve, and use this aqueous solution of ammonium sulfate, 43 g of the above-mentioned water and colloid, and fully knead in a magnetic mortar. The kneaded material was degassed in a vacuum furnace at a vacuum pressure of 4 to 7 Torr without heat...

Embodiment 3

[0073] Embodiment 3 is to use the specific surface area with embodiment 1, and the anatase type titanium dioxide that catalyst forms is different is carrier, loads ammonium sulfate, stacks V then 2 o 5 and WO 3 catalyst.

[0074] 3.1 Preparation of anatase-type porous titanium dioxide hydrated colloid

[0075] Mix 100 g of titanyl sulfate and 10% sodium hydroxide by mass, titrate it into 1 L of ion-exchanged water for 1 hour, and stir to keep the pH value between 3 and 4. Then, washing with water and filtering are repeated to make the pH value reach 5-6, and the obtained gel is dried at 180° C. to obtain a dry gel.

[0076] 3.2 Treatment of ammonium sulfate

[0077] 2.5 g of ammonium sulfate was dissolved by adding 43 g of ion-exchanged water, and this ammonium sulfate aqueous solution, 43 g of the above-mentioned water and colloid were fully kneaded in a magnetic mortar. The kneaded material was degassed in a vacuum furnace at a vacuum pressure of 4 to 7 Torr without hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com