High-processability polyurethane shoe sole material stock solution

A sole material, polyurethane technology, applied in the directions of soles, footwear, applications, etc., can solve the problems of difficult processing of the sole surface, decreased sole hardness, and increased production costs, and achieves good toughness, shape stability, and is not easy to deform and damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

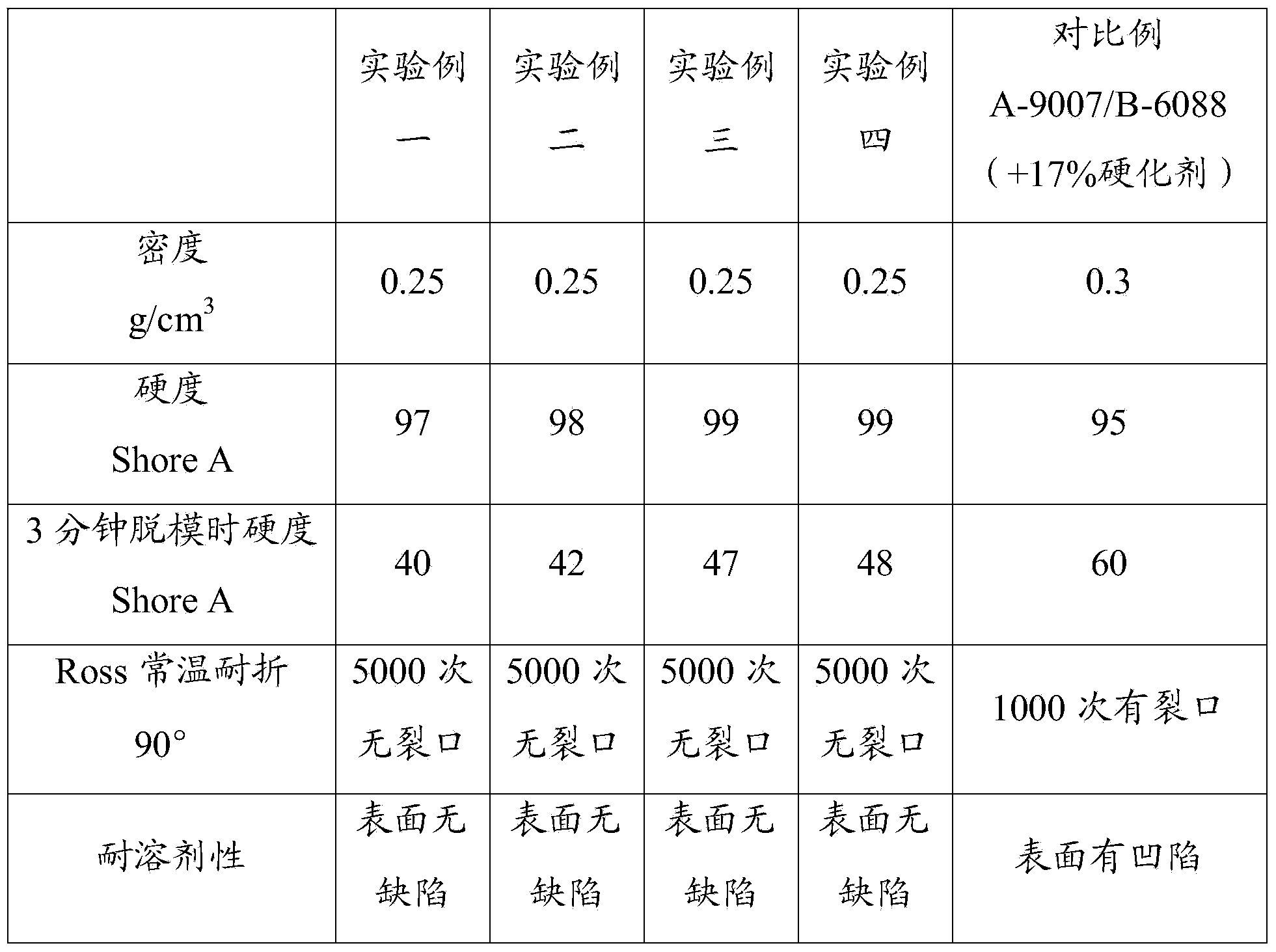

Examples

preparation example Construction

[0029] The preparation of polyester polyol can adopt the conventional preparation method of polyester polyol, and in this embodiment, nitrogen depressurization method is used for preparation.

[0030] The preparation process of the polyethylene glycol adipate diethylene glycol succinate adipate polyol that the number average molecular weight is 1500:

[0031] Add 500g of succinic acid, 1000g of adipic acid, 550g of ethylene glycol, and 450g of diethylene glycol into the reaction kettle in sequence, turn on the stirring, start to raise the temperature, and at the same time, feed nitrogen into the upper part of the reaction kettle, and keep the temperature constant when the temperature rises to 135-140°C Stabilize the dehydration rate for 1 hour (through the rectification tower, the temperature at the top of the tower is maintained at <102°C) and then continue to increase the temperature. When the temperature rises to about 180°C, nitrogen is switched from the lower part of the r...

Embodiment 1

[0041] 1. Synthesis of component A

[0042] In the reactor, adding number average molecular weight is 700 polyethylene adipate diethylene glycol glyceride polyol 1000g, number average molecular weight is 1200 polyphthalic anhydride glycol diethylene glycol adipate polyol 600g , polyethylene adipate diethylene glycol trimethylol propane polyol 400g, number average molecular weight being 2000g of polyethylene adipate diethylene glycol trimethylol propane polyol 2000 with number average molecular weight of 900, Ethylene glycol 600g, glycerin 200g, trimethylolpropane 60g, triethylenediamine ethylene glycol solution 50g, deionized water 20g, dimethylsiloxane 20g; heat up to 50-60°C, stir at high speed for one hour Then lower the temperature below 40°C, slowly add 70g of HCFC-141B, and then stir at a low speed for 0.5h to obtain component A.

[0043] 2. Synthesis of component B:

[0044] Raw materials: the polyethylene adipate diethylene glycol succinate polyol 400g with a number ...

Embodiment 2

[0047] 1. Synthesis of component A

[0048] In reactor, adding number average molecular weight is the polyethylene adipate diethylene glycol glyceride polyol 500g that number average molecular weight is 2000 polyethylene adipate diethylene glycol glyceride polyol 2200g, number average molecular weight is 600, Number-average molecular weight is 800 polyethylene adipate diethylene glycol trimethylol propane polyols 300g, number-average molecular weight is 1800 polyphthalic anhydride diethylene adipate diethylene glycol ester polyols 1000g, 400g of ethylene glycol, 100g of glycerin, 70g of ethylene glycol solution of triethylenediamine, 15g of deionized water, and 20g of dimethylsiloxane; heat up to 50°C-60°C, stir at high speed for one hour and then lower the temperature to 40°C Below ℃, slowly add 100g of HCFC-141B and stir at a low speed for 0.5h to obtain component A.

[0049] 2. Synthesis of component B:

[0050] Raw materials: 300 g of polyethylene succinate adipate dieth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com