A method of improving the yield of Ganoderma lucidum laccase by using waste paper shreds

A technology for pulverized material and waste paper, which is applied in the field of using the pulverized material of waste paper to increase the yield of Ganoderma lucidum laccase, can solve the problems of increasing the difficulty of post-processing of fermentation liquid, failing to exert the value of waste paper resources, and low level of recycling and utilization of waste paper, etc. The effect of short cycle, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

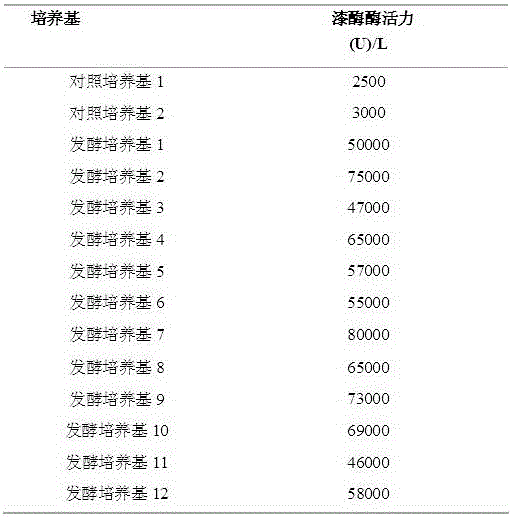

Examples

Embodiment

[0019] 1. Preparation of waste paper shreds

[0020] Soak the shredded waste paper (waste newspaper, book paper and kraft paper) in tap water for 5-8 hours, the moisture content of the waste paper is 50%-80%, dry at 100°C to constant weight, and crush it with a shredder As a powder, waste paper shreds were obtained.

[0021] 2. PDA plate culture medium

[0022] Potatoes 300g, glucose 20g, agar 18g, distilled water to make up to a total volume of 1L, sterilized for later use.

[0023] 3. Seed medium

[0024] 100g cornmeal, 100g bran, 25g peanut shell powder, KH 2 PO 4 10g, MgSO 4 5g, make up to a total volume of 1L with distilled water, and sterilize for later use.

[0025] 4. Fermentation medium

[0026] Control medium 1: cornmeal 100g, bran 10g, peanut shell powder 25g, KH 2 PO 4 10g, MgSO 4 5g, make up to 1L with distilled water, and sterilize for later use.

[0027] Control medium 2: cornmeal 100g, bran 30g, peanut shell powder 25g, KH 2 PO 4 10g, MgSO 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com