A method for extracting copper and removing iron from copper ore acid leaching solution

A technology of leachate and slag, applied in rotary drum furnaces, crucible furnaces, furnaces, etc., can solve the problems of large oxidant and neutralizer consumption, high investment and production costs, and large loss of copper with slag, and achieves low environmental protection pressure. , The effect of comprehensive utilization is good, and the consumption of oxidant is small.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

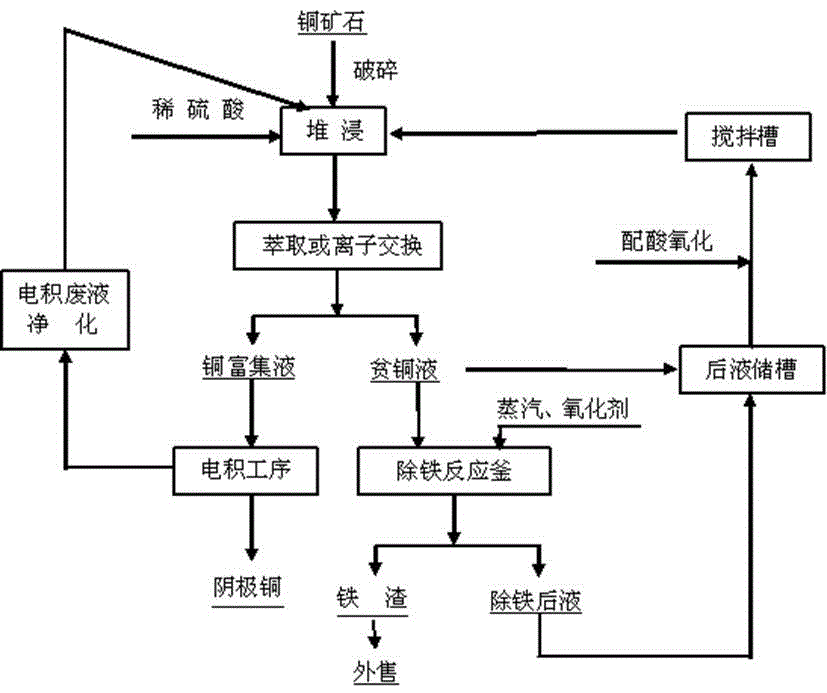

Image

Examples

Embodiment 1

[0038] Example 1: A method for extracting copper and removing iron from a copper ore acid leaching solution, comprising the following steps:

[0039] (1) Heap leaching: collect the low-grade secondary copper oxide ore and secondary copper sulfide ore produced in the process of copper ore hydrometallurgy, break them into pieces of 10-30mm in size, and then press the secondary copper oxide ore and copper sulfide ore in a ratio of 0.2~5:1 (according to the ratio of copper, iron and sulfur), transported to the storage yard for wet heap leaching; use dilute sulfuric acid as leaching agent for spraying Leaching to obtain a weakly acidic leaching solution containing 0.2-10g / L copper, 0.5-30g / L iron, and pH 1-3; send the obtained leaching solution to the copper extraction process;

[0040] (2) Copper extraction process: Extract copper from the leaching solution to obtain a copper-enriched solution containing 30-60g / L copper and less than 500mg / L iron, and obtain a copper-deficient s...

Embodiment 2

[0045] Example 2: The method for extracting copper and removing iron of copper ore acid leaching solution, operation is the same as example 1, and difference is:

[0046] (1) Heap leaching: Mix evenly according to the ratio of 0.2~1 of secondary oxide copper ore and copper sulfide ore, transport to the storage yard for wet heap leaching; use dilute sulfuric acid as leaching agent to spray and leaching to obtain 0.2~3g of copper / L, iron 0.5~10g / L, pH1~3 weakly acidic leaching solution; the obtained leaching solution is sent to the copper extraction process;

[0047] (2) Copper extraction process: copper is extracted from the leaching solution to obtain a copper enriched solution containing 30-60g / L copper and less than 500mg / L iron; the copper-poor solution after extraction contains Cu0.5g / L, Fe 2+ 14.3g / L, Fe 3+ 1.1g / L, pH1.2, the copper-poor solution is sent to the iron removal process;

[0048] (3) Iron removal process: preheat the copper-poor liquid to 90-98°C with ste...

Embodiment 3

[0050] Example 3: The method for extracting copper and removing iron of copper ore acid leaching solution, operation is the same as example 1, and difference is:

[0051] (1) Heap leaching: Mix evenly according to the ratio of 3~5:1 of secondary oxide copper ore and copper sulfide ore, transport to the storage yard for wet heap leaching; use dilute sulfuric acid as leaching agent to spray and leaching to obtain copper-containing 5 ~10g / L, iron 10~30g / L, pH 1~3 weakly acidic leachate;

[0052] (2) Copper extraction process: The leaching solution obtained by heap leaching is subjected to ion exchange adsorption through resin to obtain a copper-enriched solution containing 30-60 g / L of copper and less than 500 mg / L of iron; the obtained copper-poor solution contains Cu1. 2g / L, Fe 2+ 23.7g / L, Fe 3+ 0.8g / L, pH3.0, the copper-poor solution is sent to the iron removal process;

[0053] The copper-poor liquid is sent to the storage yard for leaching after being oxidized with an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com