Coal and sludge co-fired green power generation system with fan mill and wind-swept mill

A technology of power generation system and fan mill, applied in dewatering/drying/concentrating sludge treatment, combustion method, combustion type, etc., can solve the problems of complex system, small sludge incineration processing capacity, and high energy consumption of sludge drying, Achieving the effect of large sludge treatment capacity and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

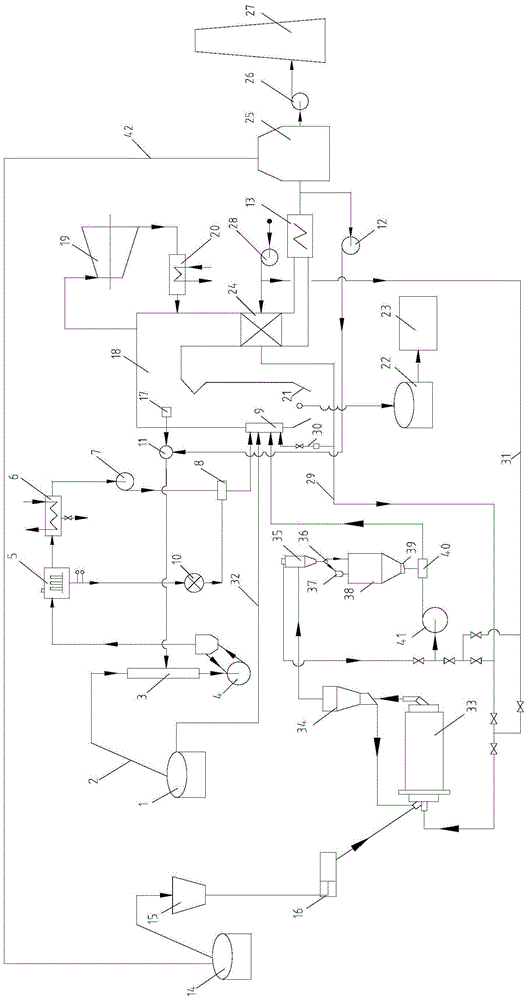

[0023] like figure 1As shown, in the coal and sludge co-firing green power generation system of the present invention, the closed sludge storage bin 1 is connected to the feed port of the drying pipe 3 through the sludge conveying device 2, and the drying The discharge port of the pipe 3 is connected to the fan mill 4, the fan mill 4 is connected to the feed port of the gas powder separator 5, the exhaust air outlet of the gas powder separator 5 is connected to the water recovery device 6, and the water recovery device 6 is connected to the exhaust gas The air blower 7 and the exhaust blower 7 are connected to the air inlet of the second air-powder mixer 8, and the powder outlet at the bottom of the air-powder separator is connected to the second powder feeder 10, and the second powder feeder 10 is connected to the second air powder feeder. The powder inlet of the mixer 8. The outlet of the second wind powder mixer 8 is connected to the burner 9 of the boiler 18 .

[0024] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com