Preparation method for lithium ion battery from electrode material with core-shell structure

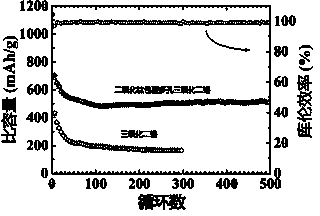

A lithium-ion battery, core-shell structure technology, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of unstable oxide electrodes, poor battery cycle performance, and metal element dissolution, and alleviate the problem of structural damage. , Improve the electrochemical performance, reduce the effect of dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Add 1.86 g of chromium trichloride hexahydrate, 1.16 g of terephthalic acid, and 50 ml of deionized water into a 70 ml hydrothermal kettle; stir for 30 minutes and react at 210°C for 24 hours to obtain the metal-organic framework material MIL Mixture of -101(Cr) and ligand. The mixture was soaked in a 1:1 mixed solution of ethanol and N,N-dimethylformamide to wash, and kept at 80°C for 10 hours. After taking it out, it was washed with ethanol and centrifuged to obtain the metal-organic framework material MIL-101 ( Cr).

[0025] 2) Add 108 ml of deionized water, 240 mg of metal-organic framework material MIL-101(Cr) and 0.996 ml of hydrochloric acid into a 150 ml beaker, stir for 10 minutes, add 12 ml of TALH dropwise and continue stirring for 5 hours to obtain a titanium dioxide package Coated MIL-101(Cr) samples.

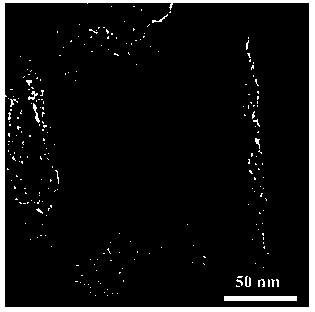

[0026] 3) Heat the sample to 350°C for 5 hours in a tube furnace under an argon atmosphere, and obtain a carbonized material after cooling; continue he...

Embodiment 2

[0033] 1) Add 0.276 g of copper nitrate 2.5 hydrate, 0.165 g of trimesic acid, 70 ml of N,N-dimethylformamide, 70 ml of ethanol and 70 ml of deionized water into a 250 ml beaker; stir at room temperature for 10 Minutes later, 0.3 ml of ammonia water with a mass concentration of 28% was added, stirring was continued for 5 hours, and the mixture was centrifuged to obtain the metal-organic framework material HKUST-1.

[0034] 2) Add 10 ml of ethanol, 50 mg of metal-organic framework material HKUST-1 and 200 μl of tetraisopropyl titanate into a 20 ml beaker, and add 1 ml of deionized water dropwise to the beaker while stirring to make titanate Tetraisopropyl ester is hydrolyzed to generate titanium dioxide that uniformly coats the surface of HKUST-1, forming a core-shell structure material.

[0035] 3) The obtained core-shell structure material was calcined at 350°C for 5 hours in an argon atmosphere, and then kept at 350°C in air for 5 hours to obtain a core-shell structure sampl...

Embodiment 3

[0038] 1) Add 0.45 g of cobalt nitrate hexahydrate, 5.5 g of dimethylimidazole and 23 ml of deionized water into a 25 ml beaker, stir at room temperature for 6 hours, wash and centrifuge to obtain metal-organic framework material ZIF-67.

[0039] 2) Add 50 mg of metal-organic framework material ZIF-67 to 5 ml of ethanol and add 500 μl of butyl titanate to obtain solution 1; and disperse 100 μl of water into 5 ml of ethanol to obtain solution 2. Solution 2 was added dropwise to solution 1, and stirred at room temperature for 5 hours to obtain a metal-organic framework material coated with titanium dioxide.

[0040] 3) The titanium dioxide-coated metal-organic framework material was calcined at 250°C for 4 hours in an argon atmosphere, and then heated to 400°C in air for 4 hours to obtain a core-shell structure material of titanium dioxide-coated zinc oxide.

[0041] 4) Mix the obtained core-shell structure sample with porous carbon and polyvinylidene fluoride to make powder, wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com