Method for producing collector for electrochemical elements, method for producing electrode for electrochemical elements, collector for electrochemical elements, electrochemical element, and coating liquid for forming collector for electrochemical elements

A technology of electrochemical components and manufacturing methods, which is applied in the direction of electrode collector coating, non-aqueous electrolyte battery electrodes, and electrode manufacturing, which can solve the problems of low conductivity and achieve the effect of low internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

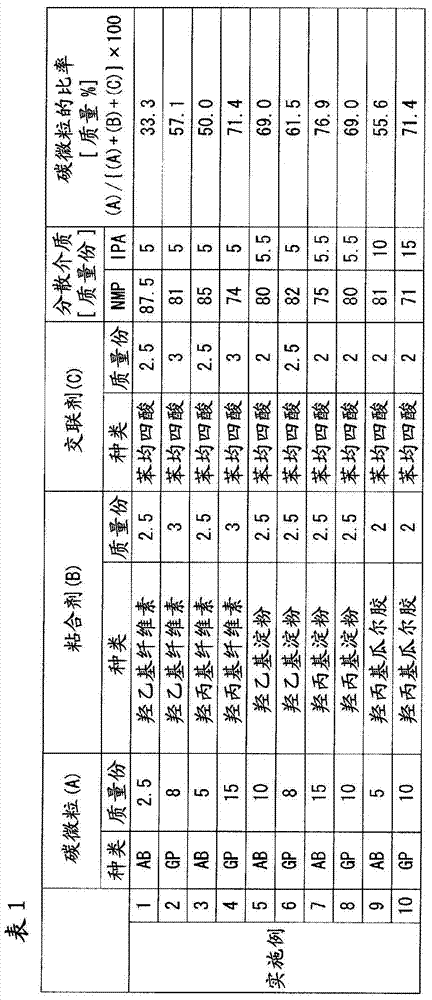

[0148] According to the formula shown in Table 1, the raw materials were put into a dissolving mixer, and mixed at a speed of 300 rpm for 10 minutes. Next, a homogenizer (manufactured by Iada Trading Co., Ltd., product name PRO200) was used to process at 20,000 rpm for 30 seconds to obtain a coating layer coating liquid in which carbon particles and the like were uniformly dispersed in the dispersion medium. Also, in Table 1, the sum of the amounts of the carbon particles (A), the binder (B), the crosslinking agent (C) and the dispersion medium is 100 parts by mass.

[0149] An aluminum foil having a thickness of 30 μm made of an alkali-washed A1085 material was prepared.

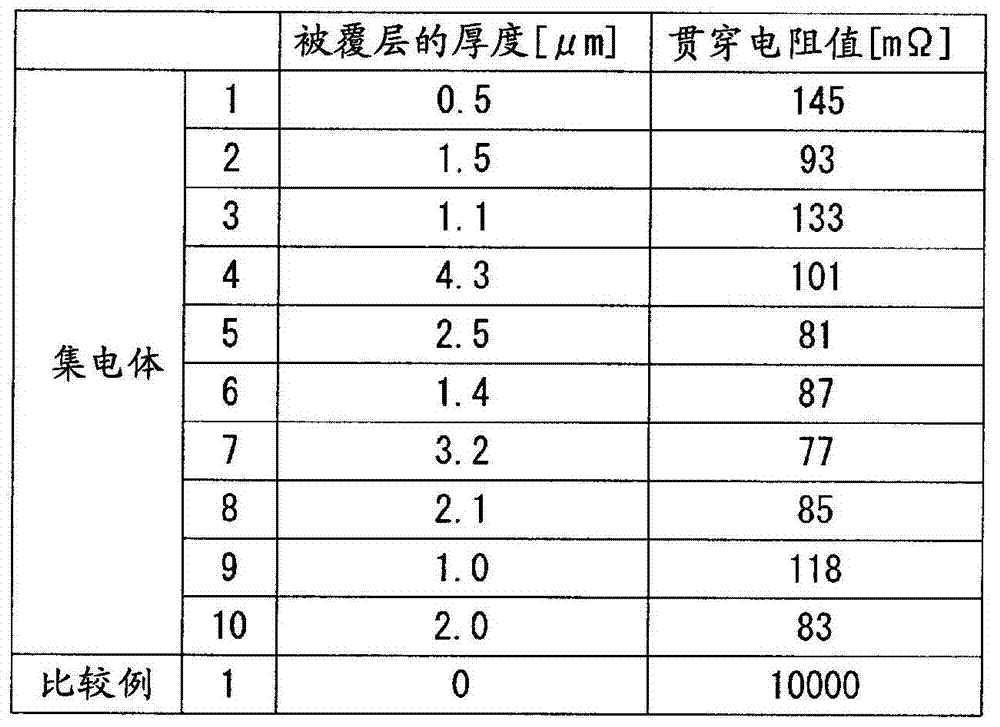

[0150] Using an applicator, the above-mentioned coating layer coating solution was applied to both sides of the aluminum foil by a casting method. Thereafter, heat treatment was carried out at 180° C. for 3 minutes, and drying was performed to obtain current collectors 1 to 10 provided with coating layers....

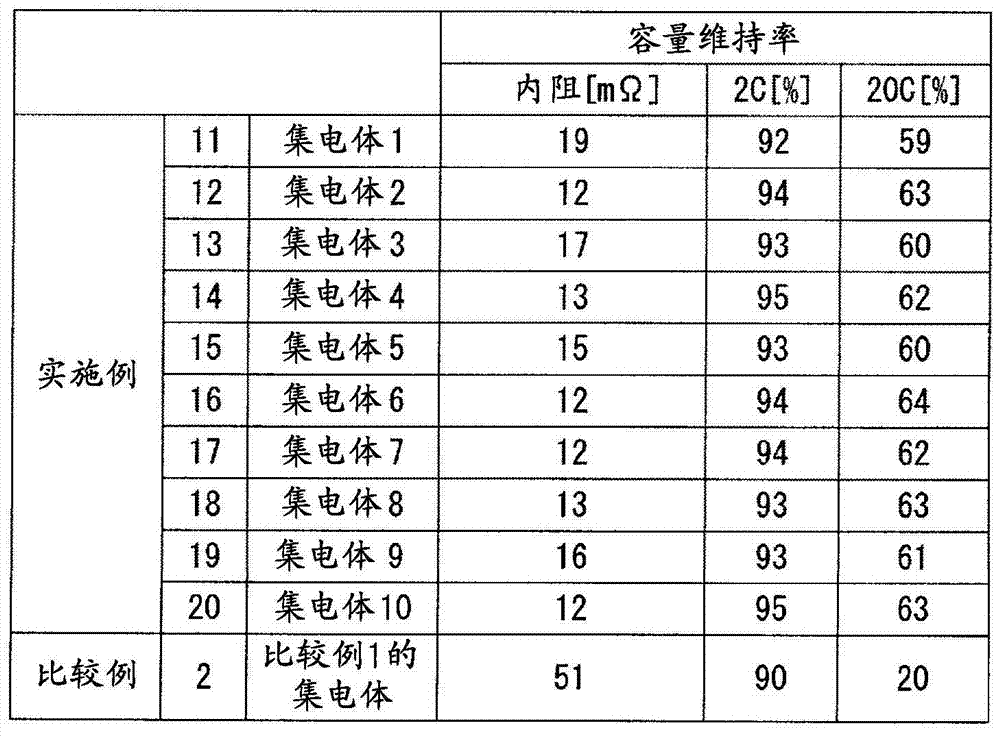

Embodiment 11~20、 comparative example 2

[0162] The current collectors obtained in Examples 1 to 10 and Comparative Example 1 were cut out into a size of 10 cm×10 cm. 95 parts by mass of lithium cobaltate (manufactured by Nippon Chemical Industry Co., Ltd., trade name Celshid C), 2 parts by mass of acetylene black (manufactured by Denka Kogyo Co., Ltd., Denka Black (powder)), polyvinylidene fluoride (Co., Ltd. 3 parts by mass of KF Polymer #1120 manufactured by KLEHA Co., Ltd., and 95 parts by mass of N-methyl-2-pyrrolidone (industrial grade) were mixed to obtain a slurry. This slurry was applied to both surfaces of the cut-out current collector. Thereafter, it was dried and pressed to form a positive electrode active material layer with a thickness of 50 μm on one side, which was used as a positive electrode.

[0163] On the other hand, 94 parts by mass of artificial graphite (manufactured by Showa Denko Co., Ltd., trade name SCMG-AR), 1 mass part of acetylene black (manufactured by Denka Kogyo Co., Ltd., trade name ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com