A preparation method of enhanced flat composite microporous membrane with improved hydrophilicity

A microporous membrane and enhanced technology, which is applied in the field of preparation of enhanced flat composite microporous membrane, can solve the problems of weak interfacial bonding force of flat composite membrane, easy breaking and falling off of membrane functional layer, insufficient mechanical strength, etc., and achieve strong interface Binding force and anti-backwashing ability, improve anti-backwashing ability, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment )

[0045] The total mass percentage of polymer film material P1 and polymethyl methacrylate P2 in the casting solution is 12-25% (increasing or decreasing by 1% within the value range can be used as an optional specific embodiment), And in terms of weighing percentage, P2 / P1=0.05~0.25 (in the value range, every increment or decrement of 0.01 can be used as an optional specific embodiment), and the mass percentage of water-soluble polymer additive is 2~12% ( Every increase or decrease by 1% within the value range can be used as an optional specific embodiment), the mass percentage of inorganic salt is 1-5% (every increase or decrease by 1% within the value range can be used as an optional Selected specific embodiment), the mass percentage of organic solvent is 58 ~ 85% (in the value range, every increment or decrement by 1% can be used as an optional specific embodiment);

[0046] The polymer membrane material is any one of polyethersulfone, polysulfone, phthalazine polyethersulfo...

Embodiment 1

[0061] Fully dissolve polymethyl methacrylate with a mass percentage of 8% in N-methylpyrrolidone (NMP), filter and defoam to prepare a coating solution for a scraping film;

[0062] Dissolve 15% polyethersulfone, 3% polymethyl methacrylate, 6% polyvinylpyrrolidone, 4% polyethylene glycol, and 2% lithium chloride in 70% N- In methylpyrrolidone (NMP) organic solvent, stir at 60°C for 48 hours until the polymer is completely dissolved, mix thoroughly to make a uniform casting solution, filter, vacuumize and defoam, and then stand for use.

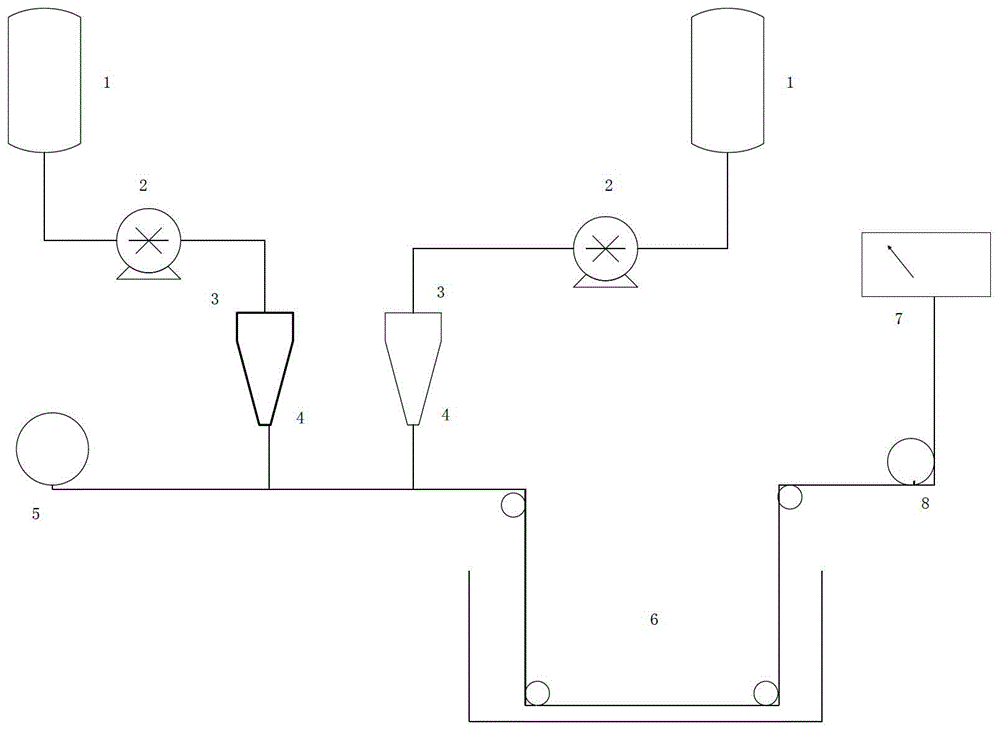

[0063] At an ambient temperature of 28°C, install the non-woven fabric 5 on the film scraping machine, control the cloth running speed controller 7 so that the non-woven cloth running speed is 0.8m / min, adjust the scraper 4 and the non-woven fabric that acts as a supporting layer The distance between 5 is 20 μm, and the coating solution with a temperature of 28 ° C is scraped and coated on the non-woven fabric through the material tank 1, the...

Embodiment 2

[0068] Fully dissolve polymethyl methacrylate with a mass percentage of 12% in the organic solvent N-methylpyrrolidone (NMP), filter and defoam to prepare a coating solution for a scraping film;

[0069] Dissolve 10% polysulfone, 2% polymethyl methacrylate, 7% polyvinylpyrrolidone, 2% polyethylene glycol, and 1% lithium chloride into 78% N-methyl chloride by mass percentage. Pyrrolidone (NMP) organic solvent, stirred at 60°C for 36 hours until the polymer was completely dissolved, mixed thoroughly to make a uniform casting solution, filtered, vacuumed and defoamed, and then left to stand for use.

[0070]At an ambient temperature of 28°C, install the non-woven fabric 5 on the film scraping machine, control the cloth running speed controller 7 so that the non-woven cloth running speed is 0.8m / min, adjust the scraper 4 and the non-woven fabric that acts as a supporting layer The distance between 5 is 20 μm, and the coating solution with a temperature of 27 ° C is scraped onto th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com