Connecting Material, Solar Cell Connecting Material, Solar Cell Module And Method For Manufacturing Same

A solar cell and connection material technology, applied in the direction of final product manufacturing, conductive adhesive connection, sustainable manufacturing/processing, etc., can solve problems such as cracking and warping of solar cell units, and achieve resistance rise suppression and connection reliability excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0123] The present invention will be further described in detail based on examples and comparative examples below, but the present invention is not limited to these examples.

[0124] [Resistance value evaluation method A]

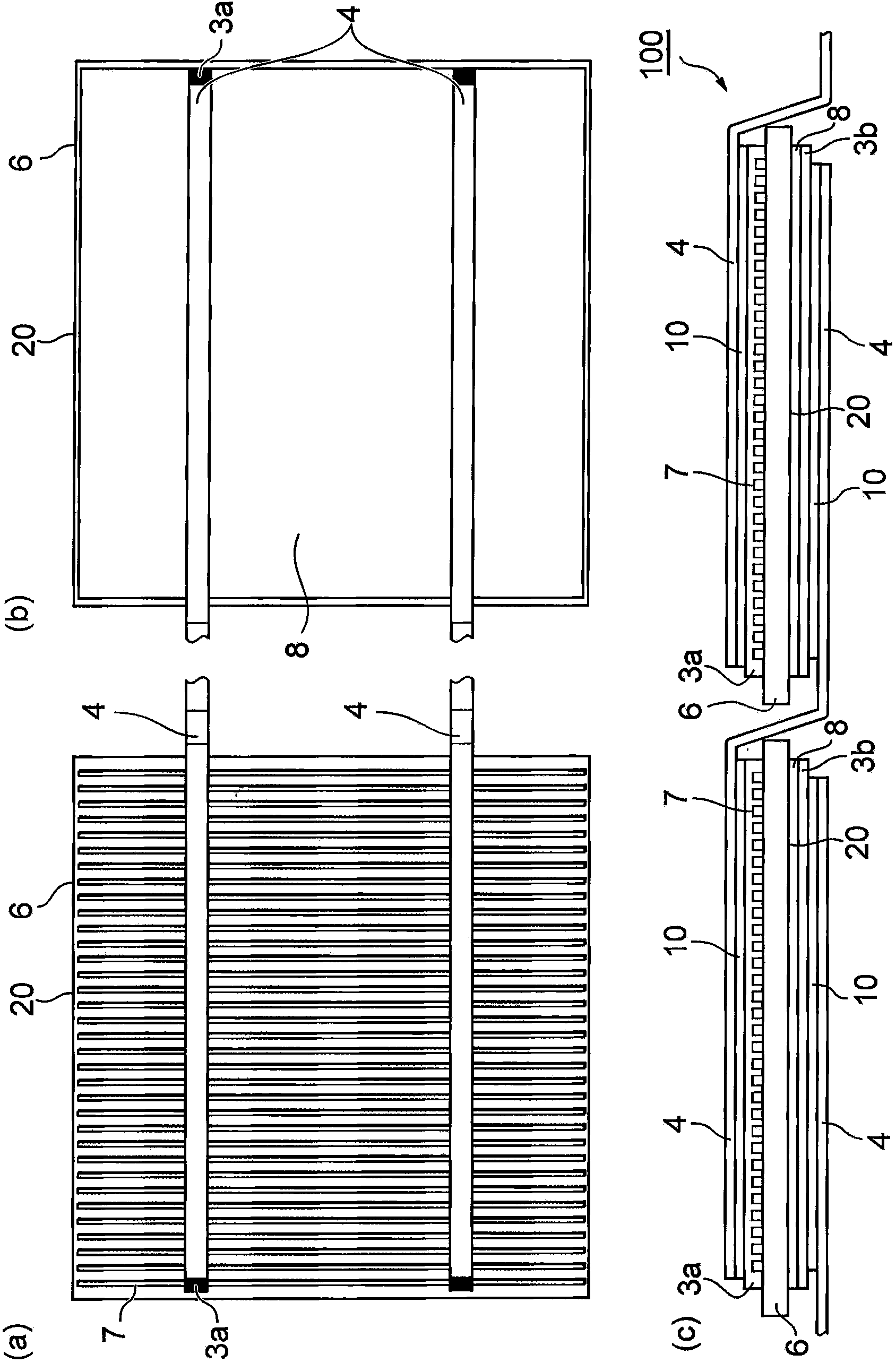

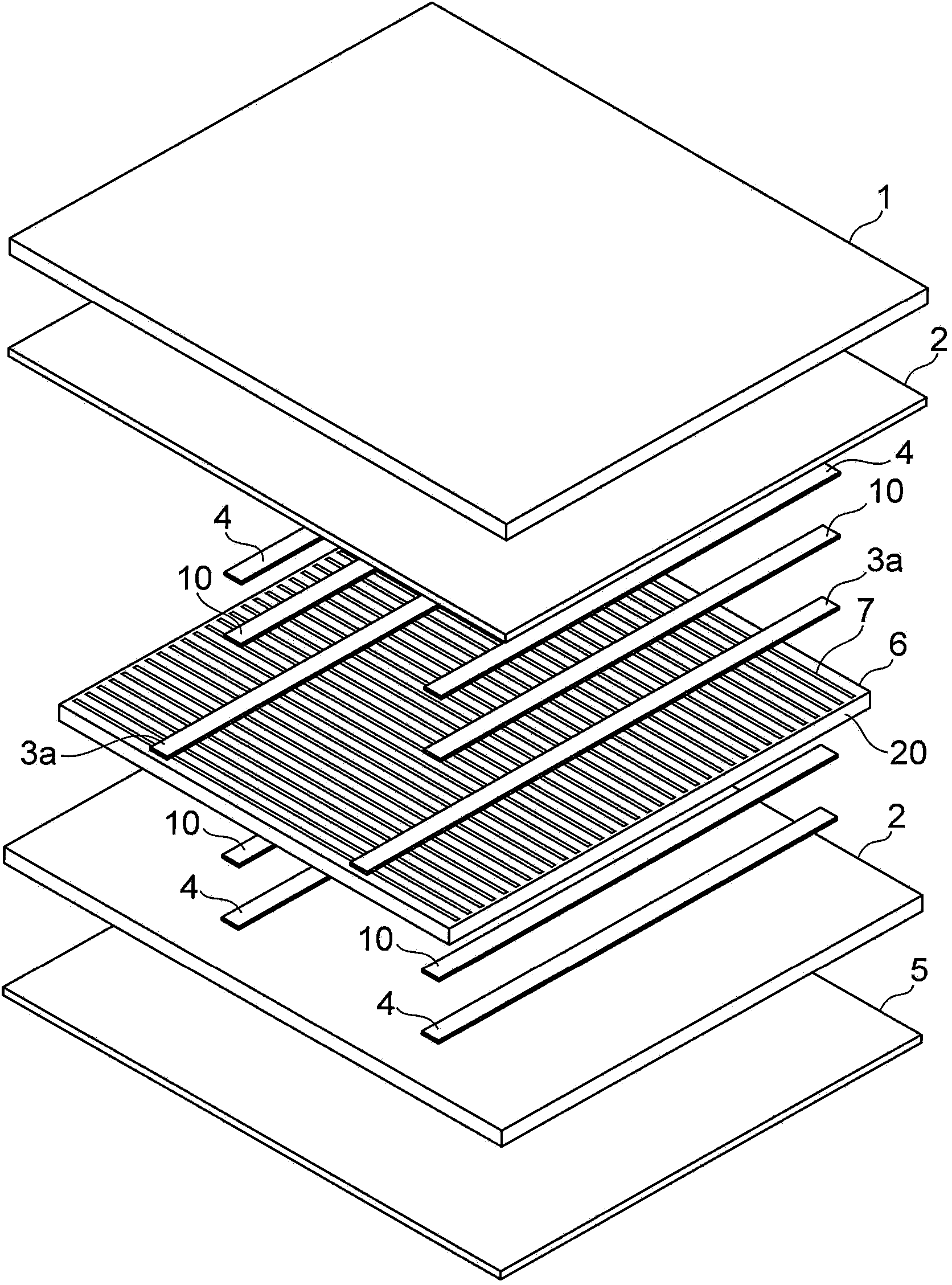

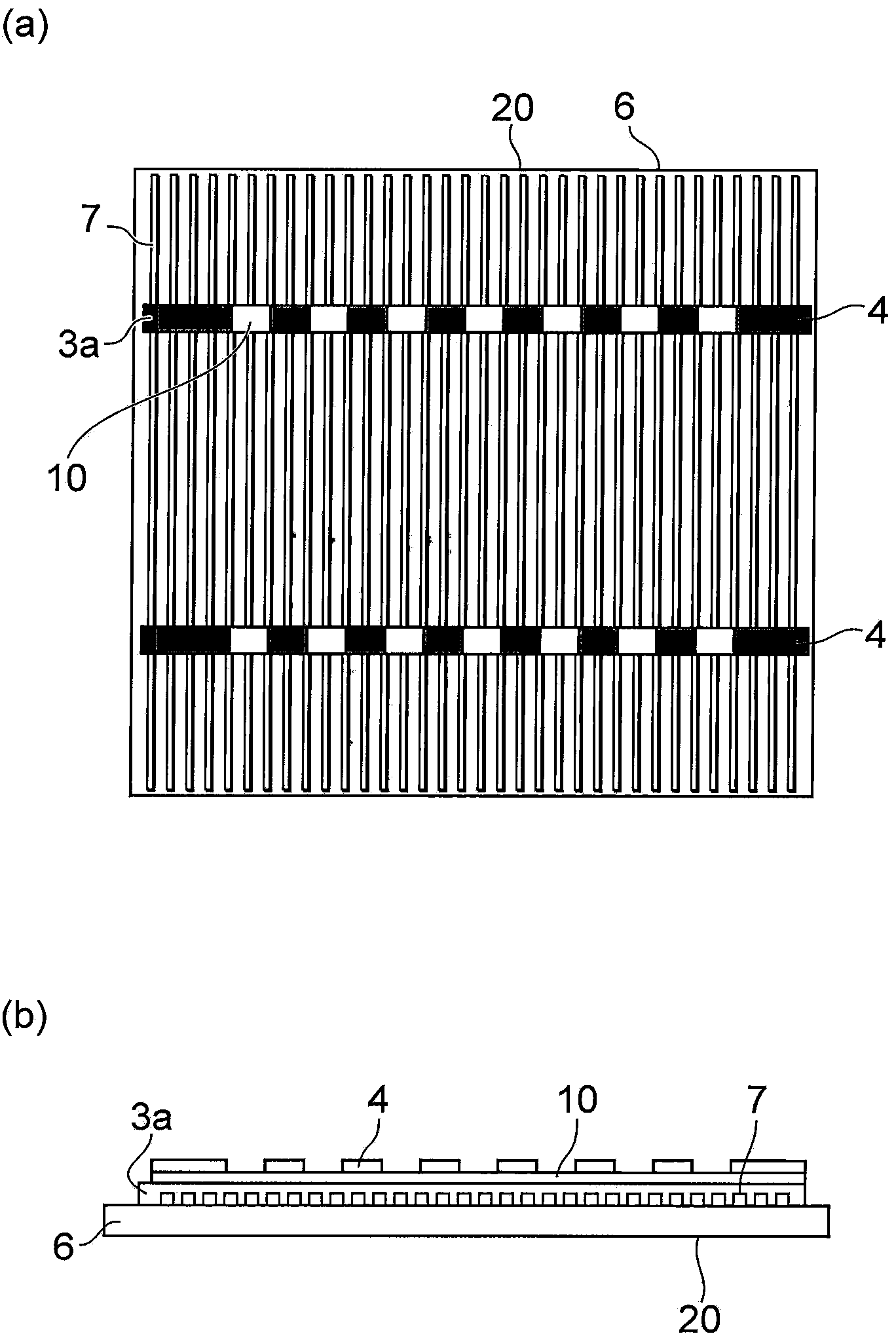

[0125] The following is based on image 3 (a) and (b) The evaluation method of the resistance value of the connection material manufactured in the Example is demonstrated.

[0126]The connection material was bonded to the Ag electrode of the 5-inch solar battery cell 20 on which the Ag electrode (bus bar electrode 3 a ) was formed on the surface using a laminator. Next, the polyethylene as the supporting film was peeled off from the connecting material, and the tab wires (wiring member 4 ) cut into 5 mm were bonded as a single sheet at 5 mm intervals, and crimped under the following crimping conditions. Among them, the both ends of the Ag electrode on the solar battery cell 20 are tab wires cut to 15 mm. The resistance value of the sample thus obtained ...

Synthetic example 1A~6A

[0132] [Synthesis Examples 1A to 6A: Synthesis of Acrylic Resin]

[0133] Synthesis examples of acrylic resins are shown below. Synthesis was performed under the same conditions except for changing the amount of monomers used and the type of monomers. A summary of the materials used is collectively shown in Table 1A. In addition, the amounts and types of monomers used for the acrylic resins obtained in Synthesis Examples 1A to 6A, and resin properties are shown in Table 2A.

[0134] [Table 1A]

[0135]

methyl ethyl ketone

(First)

(Second)

polymerization initiator

(C)

2-methacryloxyethyl isocyanate (MOI)

[0136] (Synthesis of matrix resin)

[0137] The monomer (A) shown in Table 1A and methyl ethyl ketone (MEK) were added to a 1 L beaker and mixed. After confirming that the copolymerized monomers are sufficiently compatible, a predetermined amount of azobisisobutyronitrile wa...

Embodiment 1A

[0157] As shown in Table 3A, 30 parts by mass of the acrylic resin obtained in the above Synthesis Example 1A as (A) acrylic resin, 30 parts by mass of isocyanuric acid EO-modified acrylate as (B) polymerizable compound, dihydroxy 5 parts by mass of methyltricyclodecane diacrylate, 10 parts by mass of BPA type epoxy diacrylate, 5 parts by mass of PEROYL L as (C) polymerization initiator, (D) conductive particles with an average particle diameter of 5 μm 10 parts by mass of Ni particles and 30 parts by mass of urethane acrylate resin as other components were mixed. This mixed solution was applied onto a PET film as a support film using an applicator, and dried in a dryer at 70° C. for 3 minutes to obtain a film-shaped connection material (conductive adhesive film) having a thickness of 25 μm. The connection reliability evaluation was performed on the obtained connection material according to the above-mentioned [connection reliability evaluation method A]. The results are show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com