Preparation method of sterilization type compound protein enzymolysed and fermented dairy product

A compound protease and sterilization technology, applied in the field of dairy products, can solve the problems of unfavorable sales channel promotion, poor product flavor, and low nutritional value, and achieve the effects of improving product quality, perfect fermentation state, and high nutritional value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

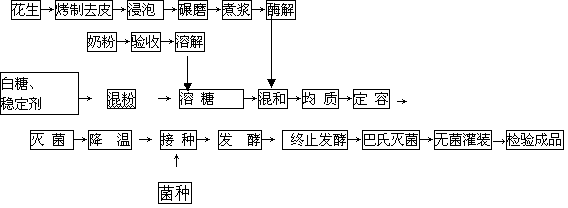

[0037] A method for preparing a sterilized compound proteolysis fermented milk product, comprising the following steps:

[0038] (1) Screening of milk sources: select milk that meets the requirements; select high-quality animal protein raw materials, which is conducive to improving product quality and improving the fermentation state.

[0039] (2) Peanut processing: Peanuts are processed into peanut pulp through roasting, soaking, grinding, boiling, and enzymatic hydrolysis;

[0040] The specific operation steps of peanut processing are as follows:

[0041] Roasting: Peanuts are screened and shelled, roasted and dried at 100°C for 50 minutes to remove the coating to make peanut kernels; suitable roasting temperature can make peanuts produce roasted flavor, and at the same time inactivate the enzymes in peanuts.

[0042] Soaking: Soak the peanut kernels in 0.1% concentrated soda water at a temperature of 60°C to make the peanut kernels fully absorb water. After soaking, rins...

Embodiment 2

[0058] A method for preparing a sterilized compound proteolysis fermented milk product, comprising the following steps:

[0059] (1) Milk source testing and screening: Antibiotics and somatic cell tests are performed on the milk source, and milk that meets the requirements is selected;

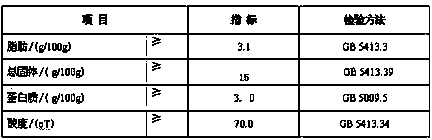

[0060] Somatic cells ≤ 50,000 / ml, total number of colonies: ≤ 100,000 cfu / ml, spores: ≤ 100 cfu / ml, heat-resistant spores ≤ 10 cfu / ml. Selecting high-quality animal protein raw materials is conducive to improving product quality and improving the fermentation state.

[0061] The milk is non-antibiotic liquid milk or milk powder. Dissolve the milk powder before use: heat the pure water to 65°C-70°C, mix the milk powder and pure water according to the mass ratio of 1:8, use high-speed stirring to mix and dissolve, and mix with syrup and stabilizer The solution is mixed well.

[0062] (2) Peanut processing: Peanuts are processed into peanut pulp through roasting, soaking, grinding, boiling, and...

Embodiment 3

[0082] A method for preparing a sterilized compound proteolysis fermented milk product, comprising the following steps:

[0083] (1) Acceptance of milk source: Antibiotic-free milk source screening: Select non-antibiotic milk or milk powder as the milk source, put it in the designated milk tank, test the milk source for antibiotics, somatic cells, etc., and make a record. In production, the quality inspection department will do a small test. The specific method is as follows: Milk (milk powder needs to be reduced by adding water in proportion) is sterilized at 95°C for 5 minutes, cooled to 43°C, and 200ml of sterilized milk is poured into a 500ml triangular bottle (sterilized ), add 10ml of activated strain (finished product), stir evenly, put it in a 43°C incubator for fermentation, and make 3-4 parallel samples at the same time, after 2-3 hours, tilt the conical flask to observe if the milk has clotted, Then the milk can be used as fermentation raw material. Milk powder dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com